- Joined

- March 13, 2005

- Messages

- 7,262

- Reaction score

- 22

- City, State

- Martinsburg WV

- Year, Model & Trim Level

- 84 BII "Li'l Samson"

I saw a magazine article that showed someone doing some emergency welding using their 12v battery as a welder. I'm wondering has anyone here done this and just what do you need as far as stinger end and ground?

If I remember they used a set of jumper cables which I carry. Then all I would have to do is throw some welding rods in the truck.

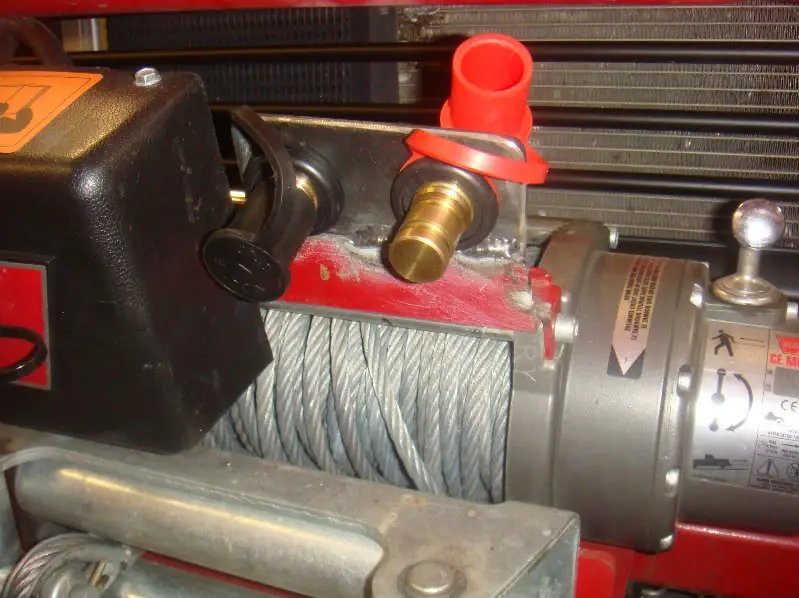

I'm in the process of installing a remote 12V set of terminals and just thought that it may be worth the while to rig up something. Unless it's just a waste of time as far as the welding part is concerned.

I would think that if it did work that it would just be for tacking something like a tail pipe hanger

If I remember they used a set of jumper cables which I carry. Then all I would have to do is throw some welding rods in the truck.

I'm in the process of installing a remote 12V set of terminals and just thought that it may be worth the while to rig up something. Unless it's just a waste of time as far as the welding part is concerned.

I would think that if it did work that it would just be for tacking something like a tail pipe hanger