Mr. Alligator

Explorer Addict

- Joined

- November 30, 2014

- Messages

- 1,296

- Reaction score

- 1,049

- City, State

- Tampa, Florida

- Year, Model & Trim Level

- 1997 XLT Explorer

On these twenty five (+) year old trucks, weatherstripping is starting to flatten, shrink, tear, and collapse. I had replaced mine as needed with salvage weatherstripping, but it was always as old as the OEM I was replacing … Finally decided to replace mine with new weatherstripping. Here are some old and new photo comparisons. The project is fairly straight forward, and patience is your best friend.

The essential tools: a T-50 torx bit and ratchet, a dremel to cut the weatherstripping, a trim panel removal tool. and a mallet. You could cut the weatherstripping with tin snips, but it might not be as clean. The mallet is just to slightly tap the weatherstripping in place… obviously, this is a project where force should be avoided.

Obtained the new weatherstripping from 1A Auto. It is standard material, and the front and rear appear the same, except for length. The new weatherstripping material seems well made, but each section was about 18” too long… better than too short, but needed to be cut. Also, the two front sections were about about $40 cheaper than the two rear sections, which were sold separately. The rear door sections were “no longer manufactured”, or something like that. But they all were more than long enough and otherwise identical, so it would have been possible to order two sets of front stripping, and save $40.

It may have been possible, but difficult and annoying, to do this by loosening the trim pieces. I found a salvage vehicle with very nice trim pieces, and replaced all of the trim in my truck while I was doing this project. if you just try to loosen the trim, you are much more like to get a little too aggressive and break plastic.

But either way, it is good to know where the clips are and what is going on when loosening or removing the interior trim. (Sine the weatherstripping is attached to the body of the truck, the door panels were not removed.)

It is best practice to do this one side at a time, in case you need to use the other side as a reference.

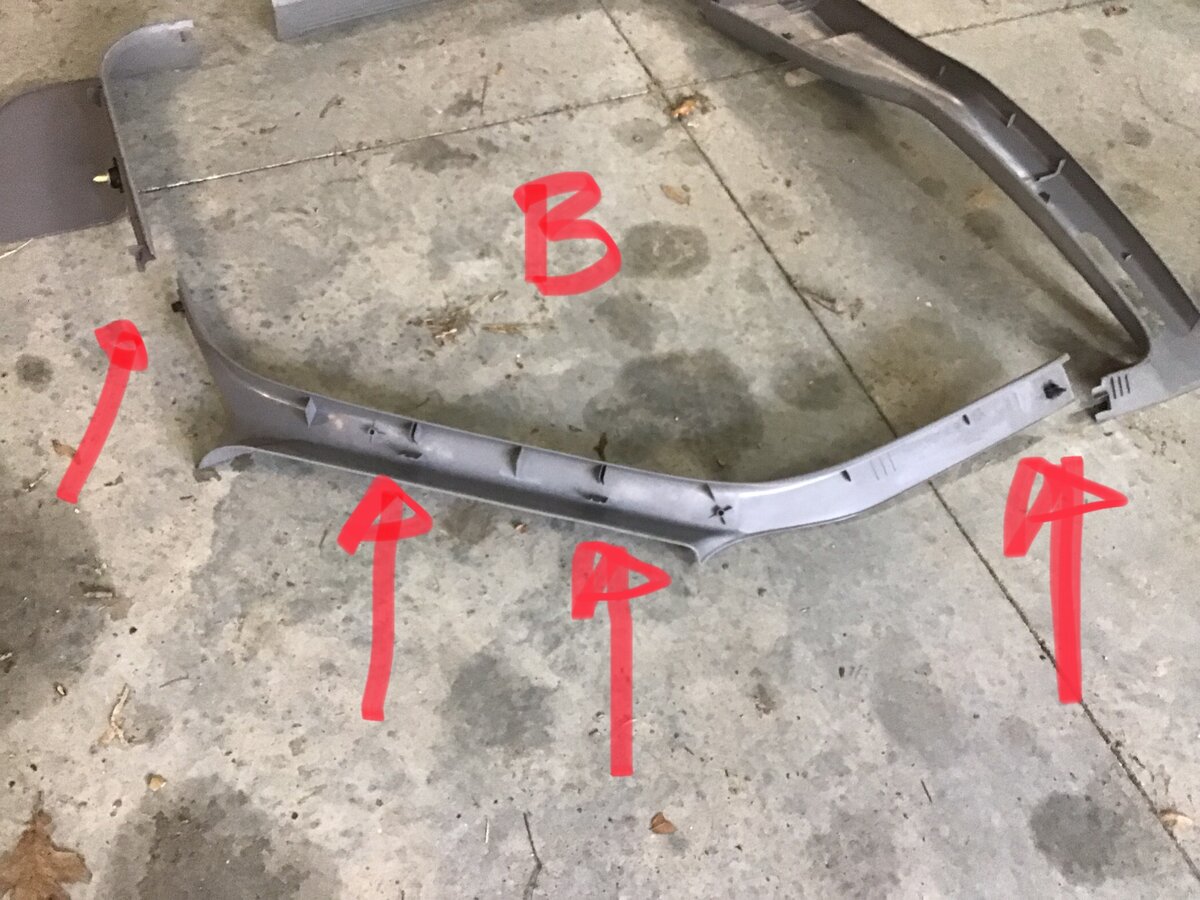

Below is a photo of the interior trim panels laid out right side up, then flipped over….

Flipped over….

Photos of each piece follows, and clips and fasteners are located and identified.

Part A: Kick panel. One Christmas tree fastener behind the parking brake. Both ends are secured by the adjacent trim piece sliding over it.

Part B: Covers the pillar from the kick panel, to above the dash board. There are metal clips on either end that secure the adjacent trim pieces. There are plastic tongs in the middle - behind the trim that secure into metal clips. The metal clips themselves do NOT to be removed, and can remain attached to the truck body.

Part C: Lower trim cover for the middle pillar. Bottom metal clips pull out from the channel on the floor. Upper clips squeeze into the trim piece above this section.

The drivers seat belt retractor mechanism is covered by this piece. After some effort, it did not seem that the retractor spring could be accessed, oiled, or tightened without the very real possibility of breaking more plastic retainer pieces and making this project rather nasty. Left my seat belt tension alone, but did spray silicone on the lower section of the belt which seemed to help, for now.

Part D: seat belt fastener, removed with T-50 torx bit, secures this, and there is a Christmas tree fastener on top. Panel below has two clips that secure the bottom of this trim piece. The front seat belt itself also slides through the part of this section. If you need to remove the entire trim piece, remove the 3/4 SAE bolt which attaches the front seat belt to the floor. Do NOT forget to slip the front seat belt through this trim before closing things up. Or you will probably get annoyed.

Note: that the coat hanger is secured by a small bolt, either 5.5mm or 7/32 SAE will work. But you need a deep socket. OR drill the coat hanger bolt hole out a little with a large drill bit so that a standard 3/8 drive socket will slip in. This is what I did years ago…. you will never notice.

Part E. The top has Christmas tree fasteners. The window sill has smaller Christmas tree fasteners. The bottom lip has two or three small sheet metal screws that pin into the floor of the cargo bed. The foot of this part is covered by the adjacent trim. Be careful with the electric connector for the lock switch. If the little plastic fasteners for the electric lock connection break, you can use a zip tie through the fasteners to hold the switch connection in place.

Note that when you remove this trim piece, it is a good time to use a 9mm wrench to snug up the small nuts that hood the cargo glass to the truck. When these get loose, you could have leaks.

The rear seat belt itself also slides through the part of this section. If you need to remove the entire trim piece, remove the 3/4 SAE bolt which attaches the rear seat belt to the floor. Do NOT forget to slip the rear seat belt through this trim before closing things up. Or you will probably get annoyed.

Finally, the cargo panel box on the passenger side…. This is secured by plastic clips that can be removed. You can tighten the top line on your cargo storage net with a knot and a zip tie. Replacement of the cargo net itse might be more difficult, especially with the plastic parts. These were not really meant to be removed or serviced, and I did not want to make this project that extensive.

When you place the new trim strip on the body of the truck, try not to stretch it. Be careful to push it all the way on, especially in the corner areas with tight bends.

and you can leave about an extra inch on the trim, and jam the ends together to delay shrinkage issues.

After completion, your doors will either open and shut extremely well, like some of mine, or be a little tight and hard to close, like the rest of mine. If a door is a little difficult to close, just adjust the striker.

Good luck with this Project. Seemed worthwhile to me.

The essential tools: a T-50 torx bit and ratchet, a dremel to cut the weatherstripping, a trim panel removal tool. and a mallet. You could cut the weatherstripping with tin snips, but it might not be as clean. The mallet is just to slightly tap the weatherstripping in place… obviously, this is a project where force should be avoided.

Obtained the new weatherstripping from 1A Auto. It is standard material, and the front and rear appear the same, except for length. The new weatherstripping material seems well made, but each section was about 18” too long… better than too short, but needed to be cut. Also, the two front sections were about about $40 cheaper than the two rear sections, which were sold separately. The rear door sections were “no longer manufactured”, or something like that. But they all were more than long enough and otherwise identical, so it would have been possible to order two sets of front stripping, and save $40.

It may have been possible, but difficult and annoying, to do this by loosening the trim pieces. I found a salvage vehicle with very nice trim pieces, and replaced all of the trim in my truck while I was doing this project. if you just try to loosen the trim, you are much more like to get a little too aggressive and break plastic.

But either way, it is good to know where the clips are and what is going on when loosening or removing the interior trim. (Sine the weatherstripping is attached to the body of the truck, the door panels were not removed.)

It is best practice to do this one side at a time, in case you need to use the other side as a reference.

Below is a photo of the interior trim panels laid out right side up, then flipped over….

Flipped over….

Photos of each piece follows, and clips and fasteners are located and identified.

Part A: Kick panel. One Christmas tree fastener behind the parking brake. Both ends are secured by the adjacent trim piece sliding over it.

Part B: Covers the pillar from the kick panel, to above the dash board. There are metal clips on either end that secure the adjacent trim pieces. There are plastic tongs in the middle - behind the trim that secure into metal clips. The metal clips themselves do NOT to be removed, and can remain attached to the truck body.

Part C: Lower trim cover for the middle pillar. Bottom metal clips pull out from the channel on the floor. Upper clips squeeze into the trim piece above this section.

The drivers seat belt retractor mechanism is covered by this piece. After some effort, it did not seem that the retractor spring could be accessed, oiled, or tightened without the very real possibility of breaking more plastic retainer pieces and making this project rather nasty. Left my seat belt tension alone, but did spray silicone on the lower section of the belt which seemed to help, for now.

Part D: seat belt fastener, removed with T-50 torx bit, secures this, and there is a Christmas tree fastener on top. Panel below has two clips that secure the bottom of this trim piece. The front seat belt itself also slides through the part of this section. If you need to remove the entire trim piece, remove the 3/4 SAE bolt which attaches the front seat belt to the floor. Do NOT forget to slip the front seat belt through this trim before closing things up. Or you will probably get annoyed.

Note: that the coat hanger is secured by a small bolt, either 5.5mm or 7/32 SAE will work. But you need a deep socket. OR drill the coat hanger bolt hole out a little with a large drill bit so that a standard 3/8 drive socket will slip in. This is what I did years ago…. you will never notice.

Part E. The top has Christmas tree fasteners. The window sill has smaller Christmas tree fasteners. The bottom lip has two or three small sheet metal screws that pin into the floor of the cargo bed. The foot of this part is covered by the adjacent trim. Be careful with the electric connector for the lock switch. If the little plastic fasteners for the electric lock connection break, you can use a zip tie through the fasteners to hold the switch connection in place.

Note that when you remove this trim piece, it is a good time to use a 9mm wrench to snug up the small nuts that hood the cargo glass to the truck. When these get loose, you could have leaks.

The rear seat belt itself also slides through the part of this section. If you need to remove the entire trim piece, remove the 3/4 SAE bolt which attaches the rear seat belt to the floor. Do NOT forget to slip the rear seat belt through this trim before closing things up. Or you will probably get annoyed.

Finally, the cargo panel box on the passenger side…. This is secured by plastic clips that can be removed. You can tighten the top line on your cargo storage net with a knot and a zip tie. Replacement of the cargo net itse might be more difficult, especially with the plastic parts. These were not really meant to be removed or serviced, and I did not want to make this project that extensive.

When you place the new trim strip on the body of the truck, try not to stretch it. Be careful to push it all the way on, especially in the corner areas with tight bends.

and you can leave about an extra inch on the trim, and jam the ends together to delay shrinkage issues.

After completion, your doors will either open and shut extremely well, like some of mine, or be a little tight and hard to close, like the rest of mine. If a door is a little difficult to close, just adjust the striker.

Good luck with this Project. Seemed worthwhile to me.