- Joined

- February 8, 2003

- Messages

- 9,814

- Reaction score

- 98

- City, State

- Sacramento, CA 95827

- Year, Model & Trim Level

- 1992 XLT

EDIT: BEFORE you start out, see this is NOT an Explorer system and blow it off... stop. The procedures for recharging auto AC are the same (or 99% the same) for ANY system. What you leaern here is 100% applicable to recharging your Explorer's AC!

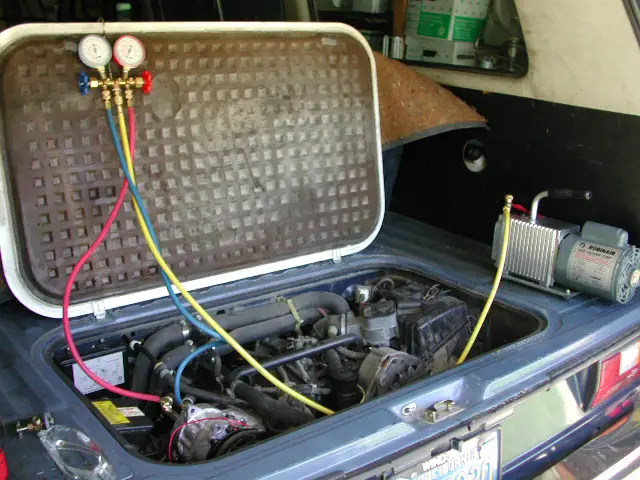

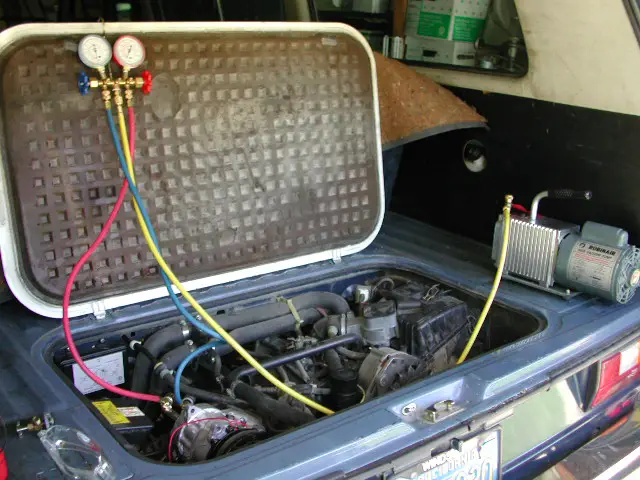

Recently I posted some info on converting to R-134 from R-12. Many posts since then have involved the aspects of how to properly charge a system. A recent project was the rebuild and recharge of a Sanden based VW bus system. (Sanden AC compressors, best of the best, even Learjet uses em). So in the interests of showing how it *ought* to be done here goes:

The setup... bus engine compartment and vacuuum pump and manifold - the system was rebuilt, and any old parts flushed, oil was added to spec, all we need at this point is to charge it with refrigerant -

The hookup at the compressor blue low/red high -

The vacuum pump -

After a few minutes of running -

On the electronic gauge at the same time -

Running about 20 minutes lowers it even more -

and about 45 mins even more - this is a good vacuum on mobile AC! No moisture or other non condensibles likely to be left in here! Note that we are not vacuuming the system (like a carpet) but evacuating it!!! This is not a process where we are "cleaning out" the system, but rather a process where we are removing all air and moisture -

Ok we are ready for refrigerant. Most important tool ? THESE !!! GOGGLES. PROTECT YOUR EYES !!!-

Ready to charge now. Hooking up the can to the charging hose, haven't punctured the can yet -

Another view, connected and ready -

With the can right side up and gaseous refrigerant ready, loosen this connection and bleed a little refrigerant through the charging hose to displace any air, then retighten it - do this for every new can you attach, you spent a lot of time getting rid of air, don't add it from your hoses !

We start by feeding liquid refrigerant into the "high" or red side, can is UPSIDE DOWN - And open the high side valve - (REMEMBER THE ENGINE IS NOT RUNNING AT THIS POINT - WE WILL NOT START THE ENGINE UNTIL LATER IN THIS PROCESS!!)

The pressures will slowly rise on the high side as the refrigerant is drawn into the evacuated system. The low side gauge will also start reflecting the pressures as they equalize within the system (high and low sides will equalize slowly in a non-running system, so you can see the pressure on either the high side OR the low side once they are equalized) -

Eventually, the first can will empty and a 2nd can, following the above purge procedure, will be started, until the system cannot take any more passively based on can pressurure. The temperature will dictate how much this is, but it's common to get into the 2nd can.... not to worry if it stops half way through, for when we cannot passively feed we can start the system and let it finish the job. Here, we have reached equilibrium pressures without any engine help - this is the low side gauge on the equalized system, easier to see more accurately the pressure on this gauge -

You can see above that the pressure is kinda like the temps on a nice day... good old R-12 closely approximates pressures for degrees F temps. In fact the red band that says R-12 is the temperature band for R-12. Ok, it's time for gas charging, so we close the high (red) side -

Now we are going to charge the rest as a gas. Through the low (blue) side. CAN UPRIGHT and once we get the engine running and the compressor and AC operating, in it goes -

As we start the engine. the high side will rise and low side will start to fall... he's the low side before we start adding gas with the engine operating the compressor-

We open the valve and start adding gas (can upright!)and the pressure jumps.

Why ? Because the system low side pressure is equalizing to can pressure, but taking it in at the same time, it will start to drop soon -

eventually the cooling can (yeah that sucker will get cold!) will again equalize pressures. You can speed things up by adding the can of refrigerant to hot water in a coffee can or similar, like this -

Once you do this the low side will jump again, but soon lower once the rest of the gas is drawn in. Here is the final charge on this system on the gauges -

Now to disconnect the gauge set. With the engine and AC running I disconnect the low side, and - this is important - add the cap, the schrader valves are a weak link in system leakage and caps really DO help!! - just make sure the rubber o-ring is inside and intact. Mineral oil it if you have some, that adds another barrier.

I leave the high side connected as I stop the engine -

The high side will SLOWLY bleed down from a HIGH pressure - time varies but wait til it is at a low pressure, this was after a few minutes, give it time - it can take a while to equalize, but be much easier to disconnect -

Last thing to do is to check for leaks. I use this sniffer to check for leaks, here at the compressor connections -

And at the main compressor seal, for the record I check underneath too, this was for photographic purposes... -

I'll also check wherever else it might be appropriate. So that done, the job is finished. In this case I knew exactly how much refrigerant to put in, if this was a top up I'd be watching low side pressures and monitoring vent temps more closely.

There is a big benefit of deep vacuum and taking a long time pulling a vacuum before you start; purging hoses to eliminate air and importantly wearing goggles. I kid you not, your eyesight is worth it, and I'm not being a woos. Please do it.

I hope this added something to our collective knowledge.

Happy, and cool, Exploring

Chris

Recently I posted some info on converting to R-134 from R-12. Many posts since then have involved the aspects of how to properly charge a system. A recent project was the rebuild and recharge of a Sanden based VW bus system. (Sanden AC compressors, best of the best, even Learjet uses em). So in the interests of showing how it *ought* to be done here goes:

The setup... bus engine compartment and vacuuum pump and manifold - the system was rebuilt, and any old parts flushed, oil was added to spec, all we need at this point is to charge it with refrigerant -

The hookup at the compressor blue low/red high -

The vacuum pump -

After a few minutes of running -

On the electronic gauge at the same time -

Running about 20 minutes lowers it even more -

and about 45 mins even more - this is a good vacuum on mobile AC! No moisture or other non condensibles likely to be left in here! Note that we are not vacuuming the system (like a carpet) but evacuating it!!! This is not a process where we are "cleaning out" the system, but rather a process where we are removing all air and moisture -

Ok we are ready for refrigerant. Most important tool ? THESE !!! GOGGLES. PROTECT YOUR EYES !!!-

Ready to charge now. Hooking up the can to the charging hose, haven't punctured the can yet -

Another view, connected and ready -

With the can right side up and gaseous refrigerant ready, loosen this connection and bleed a little refrigerant through the charging hose to displace any air, then retighten it - do this for every new can you attach, you spent a lot of time getting rid of air, don't add it from your hoses !

We start by feeding liquid refrigerant into the "high" or red side, can is UPSIDE DOWN - And open the high side valve - (REMEMBER THE ENGINE IS NOT RUNNING AT THIS POINT - WE WILL NOT START THE ENGINE UNTIL LATER IN THIS PROCESS!!)

The pressures will slowly rise on the high side as the refrigerant is drawn into the evacuated system. The low side gauge will also start reflecting the pressures as they equalize within the system (high and low sides will equalize slowly in a non-running system, so you can see the pressure on either the high side OR the low side once they are equalized) -

Eventually, the first can will empty and a 2nd can, following the above purge procedure, will be started, until the system cannot take any more passively based on can pressurure. The temperature will dictate how much this is, but it's common to get into the 2nd can.... not to worry if it stops half way through, for when we cannot passively feed we can start the system and let it finish the job. Here, we have reached equilibrium pressures without any engine help - this is the low side gauge on the equalized system, easier to see more accurately the pressure on this gauge -

You can see above that the pressure is kinda like the temps on a nice day... good old R-12 closely approximates pressures for degrees F temps. In fact the red band that says R-12 is the temperature band for R-12. Ok, it's time for gas charging, so we close the high (red) side -

Now we are going to charge the rest as a gas. Through the low (blue) side. CAN UPRIGHT and once we get the engine running and the compressor and AC operating, in it goes -

As we start the engine. the high side will rise and low side will start to fall... he's the low side before we start adding gas with the engine operating the compressor-

We open the valve and start adding gas (can upright!)and the pressure jumps.

Why ? Because the system low side pressure is equalizing to can pressure, but taking it in at the same time, it will start to drop soon -

eventually the cooling can (yeah that sucker will get cold!) will again equalize pressures. You can speed things up by adding the can of refrigerant to hot water in a coffee can or similar, like this -

Once you do this the low side will jump again, but soon lower once the rest of the gas is drawn in. Here is the final charge on this system on the gauges -

Now to disconnect the gauge set. With the engine and AC running I disconnect the low side, and - this is important - add the cap, the schrader valves are a weak link in system leakage and caps really DO help!! - just make sure the rubber o-ring is inside and intact. Mineral oil it if you have some, that adds another barrier.

I leave the high side connected as I stop the engine -

The high side will SLOWLY bleed down from a HIGH pressure - time varies but wait til it is at a low pressure, this was after a few minutes, give it time - it can take a while to equalize, but be much easier to disconnect -

Last thing to do is to check for leaks. I use this sniffer to check for leaks, here at the compressor connections -

And at the main compressor seal, for the record I check underneath too, this was for photographic purposes... -

I'll also check wherever else it might be appropriate. So that done, the job is finished. In this case I knew exactly how much refrigerant to put in, if this was a top up I'd be watching low side pressures and monitoring vent temps more closely.

There is a big benefit of deep vacuum and taking a long time pulling a vacuum before you start; purging hoses to eliminate air and importantly wearing goggles. I kid you not, your eyesight is worth it, and I'm not being a woos. Please do it.

I hope this added something to our collective knowledge.

Happy, and cool, Exploring

Chris