2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,562

- Reaction score

- 349

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Rear main seal removal

When the engine is hanging on a hoist is a good time to replace the crankshaft rear main seal. The photo below of the old crankshaft rear main seal attempts to illustrate that there is a variation in the upper and lower sections of the block where the seal fits.

My Haynes manual specifies that the seal should be perpendicular to the crankshaft axis and that the tolerance is 0.015 inches. Many members have experienced leaks after replacing their rear main seal. I suspect that they may have tried to seat the new seal flush with the nonuniform block surface.

The photo below shows my seal installation tool. It is a 2 inch schedule 40 PVC coupling. The coupling inner diameter is the same as the outer diameter of the crankshaft. The coupling outer diameter is less than desired but adequate.

I used a drum sander to enlarge the coupling inner diameter until the crankshaft sleeve provided with the seal kit fit inside of the coupling as shown in the photo below.

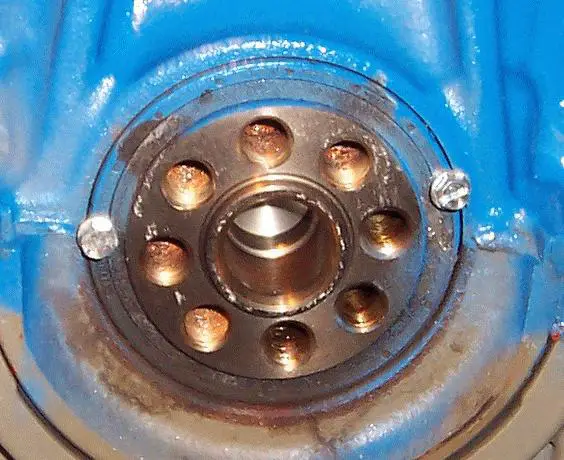

I drilled two small holes where the "dimples" are on opposite sides of the seal. I was careful not to go any deaper than when the drill broke thru the seal. I used a new drill bit so it would not "walk" away from the dimple and endanger scoring the crankshaft. After drilling the holes I inserted two hex head sheet metal screws as shown in the photo below.

When the engine is hanging on a hoist is a good time to replace the crankshaft rear main seal. The photo below of the old crankshaft rear main seal attempts to illustrate that there is a variation in the upper and lower sections of the block where the seal fits.

My Haynes manual specifies that the seal should be perpendicular to the crankshaft axis and that the tolerance is 0.015 inches. Many members have experienced leaks after replacing their rear main seal. I suspect that they may have tried to seat the new seal flush with the nonuniform block surface.

The photo below shows my seal installation tool. It is a 2 inch schedule 40 PVC coupling. The coupling inner diameter is the same as the outer diameter of the crankshaft. The coupling outer diameter is less than desired but adequate.

I used a drum sander to enlarge the coupling inner diameter until the crankshaft sleeve provided with the seal kit fit inside of the coupling as shown in the photo below.

I drilled two small holes where the "dimples" are on opposite sides of the seal. I was careful not to go any deaper than when the drill broke thru the seal. I used a new drill bit so it would not "walk" away from the dimple and endanger scoring the crankshaft. After drilling the holes I inserted two hex head sheet metal screws as shown in the photo below.

I just read over your entire thread and man this is cool as hell, I wish I was smart enough to do all this lol. But seroiusly man NICE work!

I just read over your entire thread and man this is cool as hell, I wish I was smart enough to do all this lol. But seroiusly man NICE work!