Dylan Baker

Member

- Joined

- October 2, 2019

- Messages

- 13

- Reaction score

- 4

- City, State

- Seattle

- Year, Model & Trim Level

- 06 Exp

86 F150

68 Stang

Ok, so I installed a front winch on my explorer recently, (see second picture) and since I had not really seen anyone describe how to do this besides custom fabricated bumpers, so I decided to show yall how I did it. Also for this you will have modify the plastic of the bumper. Here we go

Things you will need:

(you can get all of this at harbor freight for cheap if you want, I included a link to each of these at harbor freight, just so you can click on it and see a picture for reference.

> An 18 section of two inch hit receiver

https://www.harborfreight.com/class-iii-18-in-x-2-in- standard-receiver-tube-69815.html

> A 500 pound 2 inch hitch step receiver

5000 lb. Step Bumper Receiver

> A hitch receiver mount for winches

Hitch Receiver Mount for Winches

> A winch obviously

> some pieces of flat iron

> various long bolts, washers, lock washers, etc., size of them will depend on the winch mount and receiver you get.

NOTE: I am not responsible if you mess something up

NOTE 2: I have a bull bar on my rig, but it is not necessary for this project.

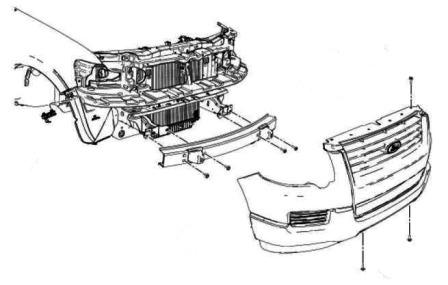

STEP 1: Remove the front bumper. to do this you will need to remove a series of plastic clip like things on the top in front of the radiator, then you need to remove the headlights as well as two smaller bolts from the underside of the bumper.

STEP 2. You will need to take off the curved piece of metal that is the actual bumper.

STEP 3: Take the 18 inch piece of two inch receiver and cut one of the ends off. You need to cut the end off that the trailer hitch would attach to so that you have a long chunk of two inch square tube. make sure to cut tube behind the hole where the pin would go to secure the trailer hitch.

STEP 4:

Take the hitch step receiver mount and place it on top of the piece of square tube. Essentially they will be stacked on top of each other so that the square tube acts as a spacer to elevate the hitch step receiver mount.

STEP 5: mark where the bolt holes in the hitch step receiver mount line up with piece of square tube. Then drill on these marks all the way through the square tube. Pick a drill bit that is the same size as the bolt holes in the hitch step receiver.

STEP 6. Remove the curved metal piece that is attached to the front of the car. it is shown in first picture. Find the center of it and find the center of the piece of square tube. Line them up and then mark the curved metal piece through the holes you just made. Then drill through the holes all the way through both sides of the curved metal piece.

STEP 7. Now you will need to take some very large bolts and put the whole thing together. You will essentially have the piece of square tube sandwiched between curved metal piece and the hitch step receiver mount. The bolts you picked will go through all three pieces.

STEP 8. Now put the curved piece of metal back on the car. It will slide on and you can bolt it back in temporarily.

STEP 9. If you look at the top

View attachment 178834

View attachment 178834

Things you will need:

(you can get all of this at harbor freight for cheap if you want, I included a link to each of these at harbor freight, just so you can click on it and see a picture for reference.

> An 18 section of two inch hit receiver

https://www.harborfreight.com/class-iii-18-in-x-2-in- standard-receiver-tube-69815.html

> A 500 pound 2 inch hitch step receiver

5000 lb. Step Bumper Receiver

> A hitch receiver mount for winches

Hitch Receiver Mount for Winches

> A winch obviously

> some pieces of flat iron

> various long bolts, washers, lock washers, etc., size of them will depend on the winch mount and receiver you get.

NOTE: I am not responsible if you mess something up

NOTE 2: I have a bull bar on my rig, but it is not necessary for this project.

STEP 1: Remove the front bumper. to do this you will need to remove a series of plastic clip like things on the top in front of the radiator, then you need to remove the headlights as well as two smaller bolts from the underside of the bumper.

STEP 2. You will need to take off the curved piece of metal that is the actual bumper.

STEP 3: Take the 18 inch piece of two inch receiver and cut one of the ends off. You need to cut the end off that the trailer hitch would attach to so that you have a long chunk of two inch square tube. make sure to cut tube behind the hole where the pin would go to secure the trailer hitch.

STEP 4:

Take the hitch step receiver mount and place it on top of the piece of square tube. Essentially they will be stacked on top of each other so that the square tube acts as a spacer to elevate the hitch step receiver mount.

STEP 5: mark where the bolt holes in the hitch step receiver mount line up with piece of square tube. Then drill on these marks all the way through the square tube. Pick a drill bit that is the same size as the bolt holes in the hitch step receiver.

STEP 6. Remove the curved metal piece that is attached to the front of the car. it is shown in first picture. Find the center of it and find the center of the piece of square tube. Line them up and then mark the curved metal piece through the holes you just made. Then drill through the holes all the way through both sides of the curved metal piece.

STEP 7. Now you will need to take some very large bolts and put the whole thing together. You will essentially have the piece of square tube sandwiched between curved metal piece and the hitch step receiver mount. The bolts you picked will go through all three pieces.

STEP 8. Now put the curved piece of metal back on the car. It will slide on and you can bolt it back in temporarily.

STEP 9. If you look at the top