Bronco638

Nobody Home

- Joined

- November 17, 2003

- Messages

- 1,585

- Reaction score

- 12

- City, State

- Elk Grove, IL

- Year, Model & Trim Level

- '17 Expedition XLT

Like most of you, I'm not very impressed by the amount of information provided by the stock Ford Explorer gauge cluster. We're all well aware of the short comings of the ‘idiot’ gauges from the factory. I purchased a two gauge pod, for the A-pillar, and two mechanical temperature gauges [Auto Meter Sport-Comp 3341 (oil) and 3351 (transmission)]. The transmission temperature gauge install will be covered in a different thread.

Ideally, the place to measure oil temperature is the oil pan. But, I’m not really prepared to drop the pan so I can drill and tap a hole for the sensor bulb. Additionally, I’m not prepared to drill and tap a hole with the pan in place and run the risk of aluminum chips circulating thru my engine’s oiling system. I’ve seen that idea mentioned on this site. As far as I’m concerned, it’s a bad idea (my $0.02). So, where else can oil be accessed to gauge temperature? The oil filter base. I kicked around the idea of a remote filter base but there isn’t a real convenient location that’s close to the engine AND off-road ‘safe’ (protected from off-road hazards). I’ve seen Aldive’s remote filter install thread.

Trans-Dapt makes a sandwich adapter that includes ports for an oil cooler (part # 1313). This adapter routes the oil out of the engine (to the cooler), back thru the filter and then back to the engine. The ports are 3/8”-14 NPT (National Pipe Thread). Auto Meter makes a 3/8”-14 adapter (part # 2263). My gauges came with 1/2”-14 adapter (part #2264).

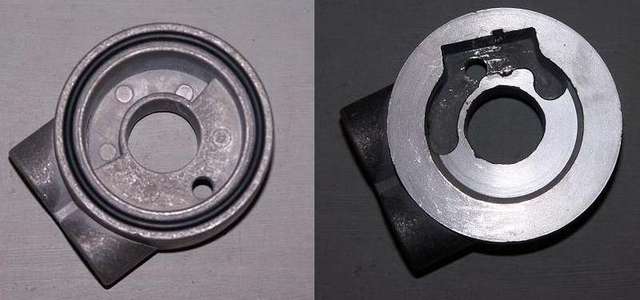

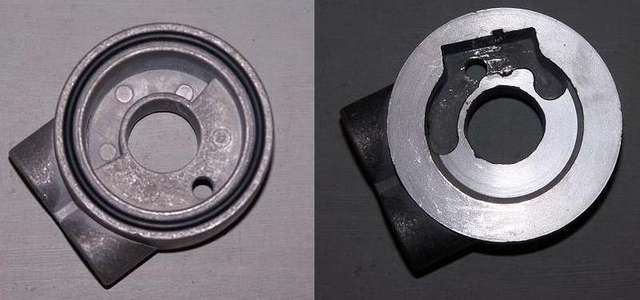

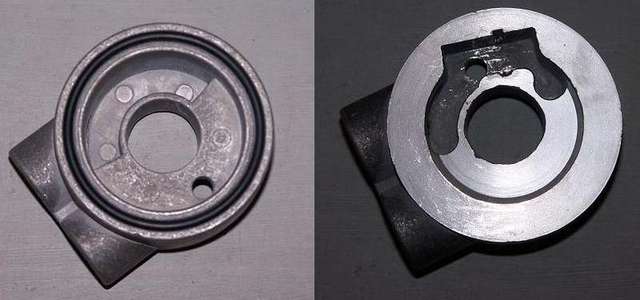

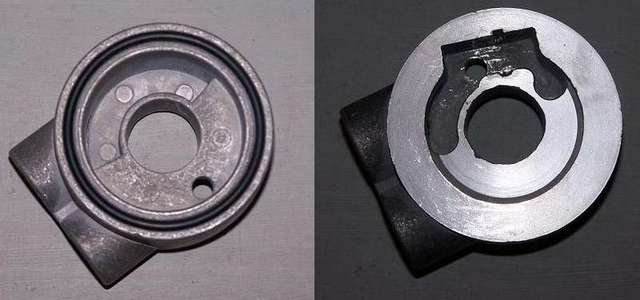

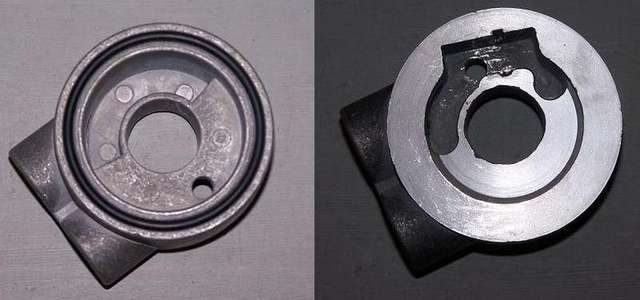

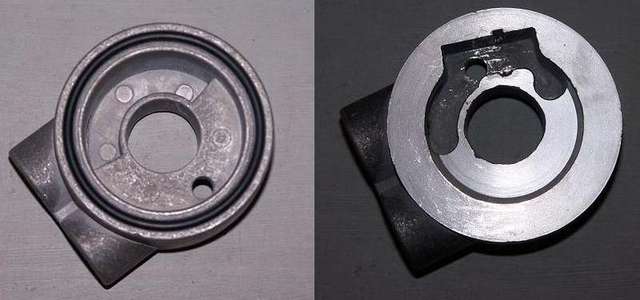

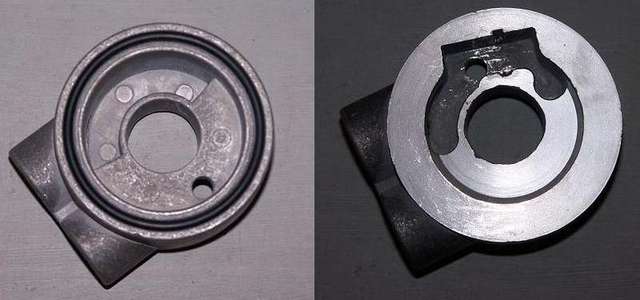

So, now you’re thinking, “if I use one of the ports for the sensor bulb, what happens with the other port?” or “how’s the oil going to flow to/from the filter if the ports are blocked?” Good questions. First, we’re going to use a 3/8”-14 brass plug to close off the other port and then we’re going to drill holes so the oil can flow thru the plate. Trans-Dapt provides a pressure and temperature sensitive by-pass valve as part of the adapter (the hole is visible in the left image, above). This allows oil to flow thru the adapter, bypassing the cooler, on cold starts. A temperature sensitive spring (already removed in the right image, above) closes this port when the oil reaches temperature. We’ll simply take advantage of this by removing the spring and opening up the port. So, how many holes will we need to drill into the adapter to provide sufficient oil flow? If we figure the area of the port (0.60” diameter.), we’ll need that much area thru the adapter. We all remember that the area of a circle is pi (3.14285) multiplied by the radius, squared. I’ll skip the math but we’ll need five 5/16” holes. You’ll notice I ended up with 9. I’d prefer something other than this adapter to be the restriction point. For those of you with access to some type of milling machine (a Bridgeport), do not be tempted to simply hog out the entire area. This portion of the casting provides the support for the oil return tube which also serves to hold the adapter in place.

Consider where to mount the pod on the A-pillar and how to route the sensor line so that the six feet of sensor line, provided with the gauge, reaches the oil source.

On my truck (’96), the fuse panel door provides perfect access to the underside of the dash. There’s a small piece of ‘weather-strip’ that conceals an access slot. This slot is large enough to accept the sensor bulb (and the associated threaded fitting) but is not large enough for the 1/2”-14 adapter. You may need to remove the spare fuse ports on the back side of the fuse panel door. I mounted the pod on the A-pillar so it just clears the dash. Mounting the pod low on the A-pillar also hides the sensor and electrical lines (for illumination) as they exit the pod.

Here's a close-up of how I ran the lines thru the opening. I used an adel clamp to keep them from rubbing on that bolt head.

There isn’t a whole lot of workspace under the dash and you will want to route the sensor line and electrical wires so that they don’t interfere with anything important (like the brake pedal, throttle cable or e-brake). I used a convenient bracket just above the brake light switch to hold the sensor line away from the brake pedal linkage. The electrical lines were zip tied to the existing harness. I used the ash tray light to supply electricity to the gauge. But, I had my console apart for another reason (vacuum disconnect mod). I’m sure there’s a more convenient electrical source. In the image below, the firewall is to your left. The upper yellow arrow indicates the sensor lines as they run under the dash. The lower yellow arrow indicates the bracket that I secured them to. The electrical lines (red & black) are simply secured to an existing harness.

This image is taken from the viewpoint of the gas pedal. The firewall is now to your right. The right yellow arrow shows where the lines enter from the fuse panel opening. The upper yellow arrow indicates their location above the brake light switch. The red/black electrical connections can also be seen.

Next, select a spot to broach the firewall. If you’ve ever looked, there isn’t any place to try to snake something thru any existing holes in the firewall. I selected a point just to the passenger side of the throttle cable. Drill thru the firewall (from engine compartment to interior). Leave the drill bit in the hole so you can locate the area of insulation you’ll need to remove from the interior side of the firewall. Use a utility knife to remove a 2” x 2” square piece of the firewall insulation from around the hole, under the dash. This stuff has a hard rubber surface and soft foam backing. Be patient trying to cut thru it. Once there is clearance around the drilled hole, I used a 1 inch hole cutter. This is an alternative to a hole saw and leaves a smooth, burr-free opening. The cutter requires a 3/8” pilot hole. Once the cutter has done it’s job, you should use a rubber grommet to protect the sensor line from the metal edge. It’s easier to snake the sensor line/bulb thru the hole and then fit the grommet over the bulb & fitting. Slide the grommet to the hole and fit it in place.

Here's a mock-up so you can see the location of the sensor bulb in the oil flow.

There’s an insulated A/C line that runs between the back of the engine and the firewall. I used this to support the sensor line as it is routed to the filter base. I also affixed the sensor line to the transmission fill tube with a zip tie. Route the sensor line to the filter base between the exhaust down pipe and the transmission. There’s a convenient loop ear (yellow arrow in image below) in the bell housing for another zip tie. Due to the proximity for the exhaust pipe, a zip tie here is very important. I used a 1.125” socket, 3” extension (a 6” extension would work better) and 1/2” drive breaker bar to tighten the adapter fitting to the filter base. I needed a piece of 2x4 that was 3.5” long, wedged between the 3/8”-14 adapter fitting and the frame, to keep the adapter base from rotating as I tightened it down. Below, you can also clearly see the 3/8"-14 adapter and 3/8" brass plug.

Ideally, this installation would be done while you’re changing engine oil. But, I did mine “on the fly” since I changed oil a month or so ago. Removing an oil filter full of oil will result in some spillage. Be sure to clean the top of the filter of any oil, especially any oil outside of the rubber sealing ring. I cleaned the side of my filter with a solvent so I could get a good grip on the filter when re-installing.

Double check your work and account for all tools. Start the engine and check for leaks. No leaks? Good! Go for a ride and check the gauge operation.

Observations:

It does take a while for temperature to register. I had water temp. way before I had oil temp. I noted approximately 205º of oil temperature at highway speeds (70 mph). Drafting (tailgating) results in an increase of approximately 10º of oil temp. Cruising around thru town (35-50 mph) saw a drop of about 10º to 15º. If you’re like me, now you’re wondering where to install the oil pressure and water temperature gauges………..

Notes:

For Summit part numbers, add the prefix; “TRD-“ to the Trans-Dapt part number(s) or add the prefix; “ATM-“ to the Auto Meter part number(s) provided in the text.

Ideally, the place to measure oil temperature is the oil pan. But, I’m not really prepared to drop the pan so I can drill and tap a hole for the sensor bulb. Additionally, I’m not prepared to drill and tap a hole with the pan in place and run the risk of aluminum chips circulating thru my engine’s oiling system. I’ve seen that idea mentioned on this site. As far as I’m concerned, it’s a bad idea (my $0.02). So, where else can oil be accessed to gauge temperature? The oil filter base. I kicked around the idea of a remote filter base but there isn’t a real convenient location that’s close to the engine AND off-road ‘safe’ (protected from off-road hazards). I’ve seen Aldive’s remote filter install thread.

Trans-Dapt makes a sandwich adapter that includes ports for an oil cooler (part # 1313). This adapter routes the oil out of the engine (to the cooler), back thru the filter and then back to the engine. The ports are 3/8”-14 NPT (National Pipe Thread). Auto Meter makes a 3/8”-14 adapter (part # 2263). My gauges came with 1/2”-14 adapter (part #2264).

So, now you’re thinking, “if I use one of the ports for the sensor bulb, what happens with the other port?” or “how’s the oil going to flow to/from the filter if the ports are blocked?” Good questions. First, we’re going to use a 3/8”-14 brass plug to close off the other port and then we’re going to drill holes so the oil can flow thru the plate. Trans-Dapt provides a pressure and temperature sensitive by-pass valve as part of the adapter (the hole is visible in the left image, above). This allows oil to flow thru the adapter, bypassing the cooler, on cold starts. A temperature sensitive spring (already removed in the right image, above) closes this port when the oil reaches temperature. We’ll simply take advantage of this by removing the spring and opening up the port. So, how many holes will we need to drill into the adapter to provide sufficient oil flow? If we figure the area of the port (0.60” diameter.), we’ll need that much area thru the adapter. We all remember that the area of a circle is pi (3.14285) multiplied by the radius, squared. I’ll skip the math but we’ll need five 5/16” holes. You’ll notice I ended up with 9. I’d prefer something other than this adapter to be the restriction point. For those of you with access to some type of milling machine (a Bridgeport), do not be tempted to simply hog out the entire area. This portion of the casting provides the support for the oil return tube which also serves to hold the adapter in place.

Consider where to mount the pod on the A-pillar and how to route the sensor line so that the six feet of sensor line, provided with the gauge, reaches the oil source.

On my truck (’96), the fuse panel door provides perfect access to the underside of the dash. There’s a small piece of ‘weather-strip’ that conceals an access slot. This slot is large enough to accept the sensor bulb (and the associated threaded fitting) but is not large enough for the 1/2”-14 adapter. You may need to remove the spare fuse ports on the back side of the fuse panel door. I mounted the pod on the A-pillar so it just clears the dash. Mounting the pod low on the A-pillar also hides the sensor and electrical lines (for illumination) as they exit the pod.

Here's a close-up of how I ran the lines thru the opening. I used an adel clamp to keep them from rubbing on that bolt head.

There isn’t a whole lot of workspace under the dash and you will want to route the sensor line and electrical wires so that they don’t interfere with anything important (like the brake pedal, throttle cable or e-brake). I used a convenient bracket just above the brake light switch to hold the sensor line away from the brake pedal linkage. The electrical lines were zip tied to the existing harness. I used the ash tray light to supply electricity to the gauge. But, I had my console apart for another reason (vacuum disconnect mod). I’m sure there’s a more convenient electrical source. In the image below, the firewall is to your left. The upper yellow arrow indicates the sensor lines as they run under the dash. The lower yellow arrow indicates the bracket that I secured them to. The electrical lines (red & black) are simply secured to an existing harness.

This image is taken from the viewpoint of the gas pedal. The firewall is now to your right. The right yellow arrow shows where the lines enter from the fuse panel opening. The upper yellow arrow indicates their location above the brake light switch. The red/black electrical connections can also be seen.

Next, select a spot to broach the firewall. If you’ve ever looked, there isn’t any place to try to snake something thru any existing holes in the firewall. I selected a point just to the passenger side of the throttle cable. Drill thru the firewall (from engine compartment to interior). Leave the drill bit in the hole so you can locate the area of insulation you’ll need to remove from the interior side of the firewall. Use a utility knife to remove a 2” x 2” square piece of the firewall insulation from around the hole, under the dash. This stuff has a hard rubber surface and soft foam backing. Be patient trying to cut thru it. Once there is clearance around the drilled hole, I used a 1 inch hole cutter. This is an alternative to a hole saw and leaves a smooth, burr-free opening. The cutter requires a 3/8” pilot hole. Once the cutter has done it’s job, you should use a rubber grommet to protect the sensor line from the metal edge. It’s easier to snake the sensor line/bulb thru the hole and then fit the grommet over the bulb & fitting. Slide the grommet to the hole and fit it in place.

Here's a mock-up so you can see the location of the sensor bulb in the oil flow.

There’s an insulated A/C line that runs between the back of the engine and the firewall. I used this to support the sensor line as it is routed to the filter base. I also affixed the sensor line to the transmission fill tube with a zip tie. Route the sensor line to the filter base between the exhaust down pipe and the transmission. There’s a convenient loop ear (yellow arrow in image below) in the bell housing for another zip tie. Due to the proximity for the exhaust pipe, a zip tie here is very important. I used a 1.125” socket, 3” extension (a 6” extension would work better) and 1/2” drive breaker bar to tighten the adapter fitting to the filter base. I needed a piece of 2x4 that was 3.5” long, wedged between the 3/8”-14 adapter fitting and the frame, to keep the adapter base from rotating as I tightened it down. Below, you can also clearly see the 3/8"-14 adapter and 3/8" brass plug.

Ideally, this installation would be done while you’re changing engine oil. But, I did mine “on the fly” since I changed oil a month or so ago. Removing an oil filter full of oil will result in some spillage. Be sure to clean the top of the filter of any oil, especially any oil outside of the rubber sealing ring. I cleaned the side of my filter with a solvent so I could get a good grip on the filter when re-installing.

Double check your work and account for all tools. Start the engine and check for leaks. No leaks? Good! Go for a ride and check the gauge operation.

Observations:

It does take a while for temperature to register. I had water temp. way before I had oil temp. I noted approximately 205º of oil temperature at highway speeds (70 mph). Drafting (tailgating) results in an increase of approximately 10º of oil temp. Cruising around thru town (35-50 mph) saw a drop of about 10º to 15º. If you’re like me, now you’re wondering where to install the oil pressure and water temperature gauges………..

Notes:

For Summit part numbers, add the prefix; “TRD-“ to the Trans-Dapt part number(s) or add the prefix; “ATM-“ to the Auto Meter part number(s) provided in the text.