TDG

Well-Known Member

- Joined

- March 22, 2001

- Messages

- 709

- Reaction score

- 11

- Location

- Los Angeles

- Year, Model & Trim Level

- 93 XLT

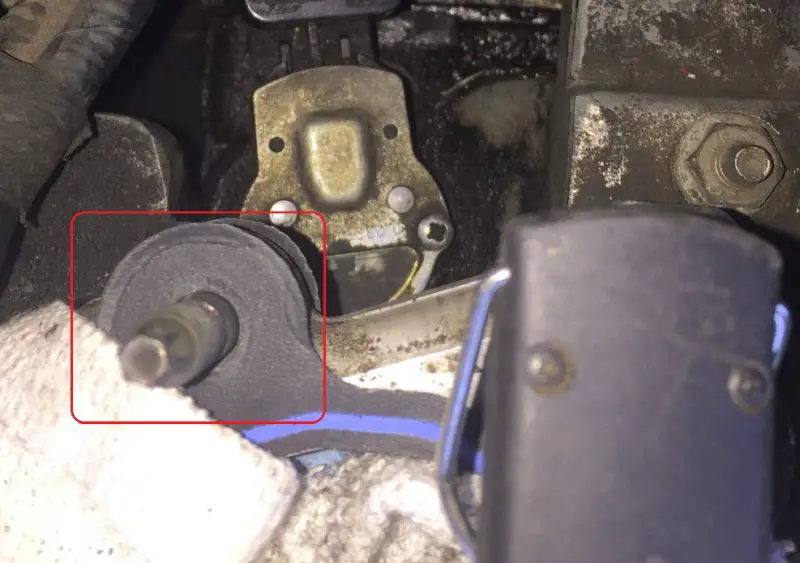

(CMP aka Cam Position Sensor / Camshaft Synchronizer)

Curious if anyone with an early 93 (one with a left over 92 engine / 90 TM heads / early accessory drive etc) has been able to remove the CMP senor without removing the lower intake manifold.

I've searched and read plenty of threads of folks with 95+s, 5.0's, Rangers etc who have managed to get them out without removing the lower intake so I'm specifically interested in hearing from someone who has done it on a 93 with with an early engine. I looked at it today on mine and can't see how it will come out without removing the lower intake unless clearance was added on the later 93+ intakes ... or it has a lot of room to angle out.

Due to my poor choice of work location (the street) and lack of interest (it still runs, just squeaks occasionally) I didn't bother rendering my truck inoperable trying to see if I could get it out.

Curious if anyone with an early 93 (one with a left over 92 engine / 90 TM heads / early accessory drive etc) has been able to remove the CMP senor without removing the lower intake manifold.

I've searched and read plenty of threads of folks with 95+s, 5.0's, Rangers etc who have managed to get them out without removing the lower intake so I'm specifically interested in hearing from someone who has done it on a 93 with with an early engine. I looked at it today on mine and can't see how it will come out without removing the lower intake unless clearance was added on the later 93+ intakes ... or it has a lot of room to angle out.

Due to my poor choice of work location (the street) and lack of interest (it still runs, just squeaks occasionally) I didn't bother rendering my truck inoperable trying to see if I could get it out.