hafcanadian

Member

- Joined

- October 18, 2013

- Messages

- 24

- Reaction score

- 17

- Location

- Oregon

- City, State

- Oregon

- Year, Model & Trim Level

- 1997 Ford Explorer Ltd.

For several years the main rear hatch on our ‘97 Limited has not always fully latched on the streetside, leaving me to discover a lighted “door ajar” lamp and annoyingly having to exit the car to reset the hatch. Pressing hard on the door’s left edge clicks the latch then, and I usually check that first now whenever I close the hatch. But it still gripes me. I lubed the latch components and seemed to relieve the issue for a couple of months, but it wasn’t permanent.

When I had the car at the shop for other service, I ran it by our tech and he made some minor changes to the left pin bolt position, loosening and retightening it. He couldn’t go too far without noticeably throwing off the alignment of the lower hatch corners with the rear cap body. He didn’t charge for the 10 minutes or so he spent on it. It seemed to be improved then and there.

But since then it still does it most of the time. If I try compensating by closing the hatch with my pushing hand halfway between the left side and the handle, that off-center twist really throws things off, the left latch bouncing away from the pin/bolt an inch or so. So I close it with the handle or push the hatch shut with a hand above or below the handle area. If needed I then may have to press the left hatch edge to get a “click” and know the latch went all the way around the pin/bolt. Usually I can tell by the gap between cap and hatch if it’s fully hooked.

The tech’s idea to move the bolt out (toward the rear) a smidge to supposedly better engage the latch arms seems sensible, but can throw off where the hatch corners meet the cap, leaving one or the other corner proud and not flush. I may try tweaking the bolt again, and more grease that seems to encourage the latch arms to wrap around the pin easier.

Has anyone here any other ideas, such as some other adjustability? Like maybe the bumper below the latch is restricting the latch arms from quite getting all the way around the pin without an extra force?

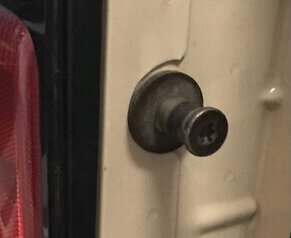

photos are 1) properly closed, 2) pin/bolt, 3) latch arm component, and 4) incomplete closure.

When I had the car at the shop for other service, I ran it by our tech and he made some minor changes to the left pin bolt position, loosening and retightening it. He couldn’t go too far without noticeably throwing off the alignment of the lower hatch corners with the rear cap body. He didn’t charge for the 10 minutes or so he spent on it. It seemed to be improved then and there.

But since then it still does it most of the time. If I try compensating by closing the hatch with my pushing hand halfway between the left side and the handle, that off-center twist really throws things off, the left latch bouncing away from the pin/bolt an inch or so. So I close it with the handle or push the hatch shut with a hand above or below the handle area. If needed I then may have to press the left hatch edge to get a “click” and know the latch went all the way around the pin/bolt. Usually I can tell by the gap between cap and hatch if it’s fully hooked.

The tech’s idea to move the bolt out (toward the rear) a smidge to supposedly better engage the latch arms seems sensible, but can throw off where the hatch corners meet the cap, leaving one or the other corner proud and not flush. I may try tweaking the bolt again, and more grease that seems to encourage the latch arms to wrap around the pin easier.

Has anyone here any other ideas, such as some other adjustability? Like maybe the bumper below the latch is restricting the latch arms from quite getting all the way around the pin without an extra force?

photos are 1) properly closed, 2) pin/bolt, 3) latch arm component, and 4) incomplete closure.

. Scratch the front ends of one Honda Accord and one Isuzu Trooper whose operators’ assumed we would not stop for yellow lights. Unfortunately my wife needed neck vertebrae surgery later as a result of the Honda. That meant, however, that I got in the habit of checking my rear view when stopping, and so pressed back into my seat and let off the brake when I saw the Isuzu not stopping, thus mitigating some of that impact. Back on topic, those incidents had no obvious or functional affect on the hatch; the latch issue appeared years later.

. Scratch the front ends of one Honda Accord and one Isuzu Trooper whose operators’ assumed we would not stop for yellow lights. Unfortunately my wife needed neck vertebrae surgery later as a result of the Honda. That meant, however, that I got in the habit of checking my rear view when stopping, and so pressed back into my seat and let off the brake when I saw the Isuzu not stopping, thus mitigating some of that impact. Back on topic, those incidents had no obvious or functional affect on the hatch; the latch issue appeared years later.