RustENutz

Active Member

- Joined

- January 24, 2007

- Messages

- 98

- Reaction score

- 1

- City, State

- Coos Bay, OR

- Year, Model & Trim Level

- 1991 XLT

Alrighty, picked up my explorer about a month ago and have been collecting parts ever since. It's getting a Dana 44 out of a 81' wagoneer via spring-over leaf springs. So far I've got the axle all cleaned up, converted to 5x5.5, with flat top knuckles and high-steer arm from Sky Manufacturing. Perches are TT Fabworks, probably not worth the money, still had to grind the diff side way out.

Springs are stock 7 leaf springs. I've got 4.5" shackles, which are already hung from my crossmember I fabbed up last weekend. Hmmmm....what else, the rear is getting a SOA with add-a-leaf as the rear leaves are sagging pretty bad. Spider-Trax adapters will match up the width and lug pattern. That's all I can think of right now. I just got a digital camera, so no pictures from before, but I'll show you what I've got so far.

My saggy rear end.

Beefy!

Stuff...

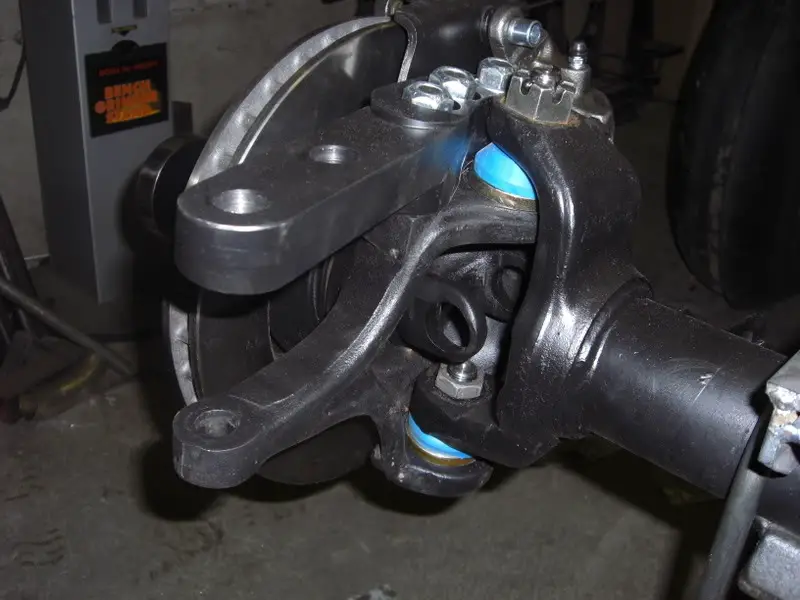

Axle, hubs/rotor, high steer arm

Spent last night fitting my perches, got them fitting pretty snug.

That's it for now, more later. The actual swap will take place not this weekend but the next.

Springs are stock 7 leaf springs. I've got 4.5" shackles, which are already hung from my crossmember I fabbed up last weekend. Hmmmm....what else, the rear is getting a SOA with add-a-leaf as the rear leaves are sagging pretty bad. Spider-Trax adapters will match up the width and lug pattern. That's all I can think of right now. I just got a digital camera, so no pictures from before, but I'll show you what I've got so far.

My saggy rear end.

Beefy!

Stuff...

Axle, hubs/rotor, high steer arm

Spent last night fitting my perches, got them fitting pretty snug.

That's it for now, more later. The actual swap will take place not this weekend but the next.

...

...