rjcooperss396

Well-Known Member

- Joined

- February 1, 2005

- Messages

- 418

- Reaction score

- 6

- City, State

- Dallas, GA

- Year, Model & Trim Level

- '95 XLT

This isn't for a truck but for my 1994 Cobra. What started this build is when I broke another rocker arm and bent another pushrod. It was the second time that it happened. The first time was about 20,000 miles prior. With 90,000 hard miles I figured the cause was weak valve springs. So I pulled the heads and and while I had them off ported them. I then took them to Pacific Engine and had them machined and a valve job done. While doing so they discovered that AFR had way too much spring pressure and that some of the springs only had .500 lift before going into coil bind. My cam with 1.7 rockers has .530 lift so it's surprising they lasted 90,000 miles.

Here's the broken rocker.

Here are some of the porting work I did on the heads and lower intake manifold.

After.

Intake manifold.

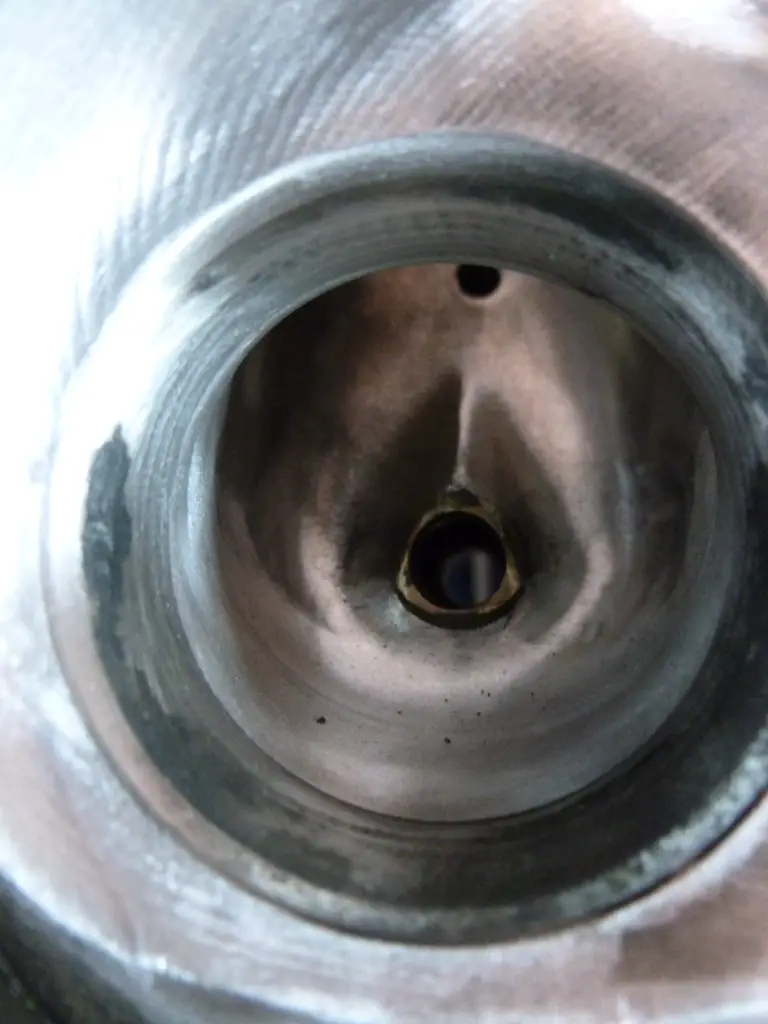

While the heads were being machined I started cleaning the carbon off the tops of the pistons and noticed a nick in one of the cylinder walls. With that discovery I really didn't want to just slap the heads back on so I started looking into the cost difference of rebuilding the 302 compared to buidling a 347. The cost diference was going to be very little so I'm building a 347.

When I pulled the shortblock from the Cobra and disassembled it I discovered what caused the nick. I found that two studs that hold a splash shield on the intake manifold had come out and fell into the pan. They must have been in there for a long time. There were nicks on the bottom of the pistons, cylinder walls, crank, rods and one lobe on the cam. Here are some pictures of the worst piston.

I ordered a short rod stroker kit from Coast High Performance a couple of weeks ago and picked it up on Friday. Over the weekend I clearanced the cylinders and today I dropped the block off at Pacific Engine. Of course I forgot the pistons so I'll be making another trip out there so they can machine the block for .004 piston to wall clearance.

Here's the broken rocker.

Here are some of the porting work I did on the heads and lower intake manifold.

After.

Intake manifold.

While the heads were being machined I started cleaning the carbon off the tops of the pistons and noticed a nick in one of the cylinder walls. With that discovery I really didn't want to just slap the heads back on so I started looking into the cost difference of rebuilding the 302 compared to buidling a 347. The cost diference was going to be very little so I'm building a 347.

When I pulled the shortblock from the Cobra and disassembled it I discovered what caused the nick. I found that two studs that hold a splash shield on the intake manifold had come out and fell into the pan. They must have been in there for a long time. There were nicks on the bottom of the pistons, cylinder walls, crank, rods and one lobe on the cam. Here are some pictures of the worst piston.

I ordered a short rod stroker kit from Coast High Performance a couple of weeks ago and picked it up on Friday. Over the weekend I clearanced the cylinders and today I dropped the block off at Pacific Engine. Of course I forgot the pistons so I'll be making another trip out there so they can machine the block for .004 piston to wall clearance.