So as you guys know I have several dashboards in the shop for this project

While messing with the 07 cluster and the wiring to it I had a question pop into my head, do any of these other late model clusters have additional wires for the indicator lights? Sure enough the 05 dash I have has a cluster that looks similar, but guess what about 30 wires instead of 15!

05 cluster

07 cluster wiring

So out come the wiring books to confirm. Sure enough the 05 cluster still has Can Bus connections BUT it also has all the wires for the gauges and indicator lights! So my plan is to use the guts from an 05 cluster and the face of the 07 cluster that came with the truck

I will likely need a Dakota digital interface to get the signal needed for the speedometer, otherwise this should be fairly straight forward. I will have to run some wires as the 07 truck does not have them.

Wires for the tach, coolant gauge, and all lights will be run and testing has begun! I feel good about this solution

As you can see most of the 05 and 07 wiring is very similar for the cluster aside from the indicator lights

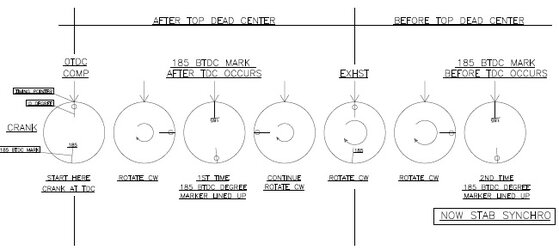

In other news I need to install the newly created hall effect type crank sensor

Removing and installing a crank sensor in a 5.0 truck with the radiator, fan, shroud, and belt in the way can be next to impossible. Not feeling well last week and not really in the mood to remove the fan and shroud and the belt I spent some time looking for another solution

FOUND IT!

This little 90 degree impact adapter from Dewalt came as a bonus with some other tools. I put it on the pegboard knowing someday I might need it. It worked like a charm!

I was able to fully remove the Holley ignition adapter harness (cam and crank sensors) from the truck quite easily!

I then reversed the crank sensor wires back to their original positions since with the hall effect sensor I no longer need them reversed

Then I cut the stock 5.0 crank sensor off and wired up the new hall effect. The power wire was already in the harness since it was designed to use a hall effect sensor.

installation was simplified using the dewalt tool I am able to get to the top crank sensor bolt.

Everything lined up, wires were carefully run and re installed into the truck

Lowdollar motors hall effect crank sensor installed

Same clearances/alignment as stocks setup

UP next now that we have a running truck and a plan for the cluster it is time for some seats!

2014 edge 10 way drivers seat with memory and heat vs stock ranger bucket. This got a little tricky

I am in the process of fabricating the mounts now

This required much trial and error ensuring I get the seats in the correct spot for a comfortable fit.

The Edge seats have much electronics inside them, the metal mounting rails are spaced further apart then a ranger seat.

I have the 14 edge wiring book so I was able to "hack" the power and the heat elements

I did a similar upgrade to my 97 F350 using heated and cooled power leather buckets from a Lincoln navigator so this is not my first rodeo. My BII has also had 01 Explorer leather with heat for 15+ years now.

This seat install has gotten very tricky, but so far I am winning.

More on that soon