- Joined

- June 17, 2004

- Messages

- 24,502

- Reaction score

- 5,106

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

The woods and outdoors are great, but you have to have the tools to survive in it well. I love the pictures, big toys/tools, and the Excursion. I was amazed by the underside of one of those when I saw one in a dealership, on a rack. The steering arms are massive.

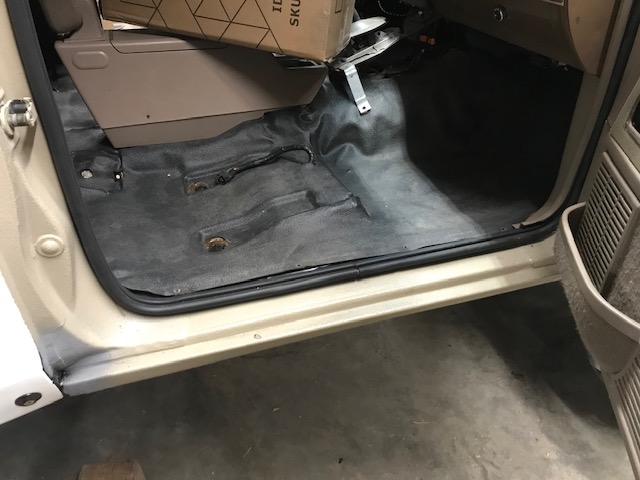

Use RTV instead of seam sealer if you can. The seam sealer is great to paint over, but it gets harder as it gets older, so it cracks and lets water into the seams(rust under any chassis). I used it on the inside in places of my 93, which was rolled and had some openings where frame work was done(pulled the right side body out). Ultra Black filled those and looks like new after 15 years.

Use RTV instead of seam sealer if you can. The seam sealer is great to paint over, but it gets harder as it gets older, so it cracks and lets water into the seams(rust under any chassis). I used it on the inside in places of my 93, which was rolled and had some openings where frame work was done(pulled the right side body out). Ultra Black filled those and looks like new after 15 years.