- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Started building a new trans mount. I have been running a similar style one for years. It just isn't as pretty so I decided to build a new one. When I had installed my doubler the stock style mounts kept breaking with the extra gearing added. Ever sense I went to this style I have never had another problem. I tacked it all together and will test fit before I do the final welds. I built it to match the factory dimensions so it will bolt in place of a stock mount.

Here it is attached to a 5speed tailhousing like what my truck has in it. Going to test fit it with an auto in a 95 ranger as my parents have one to make sure it fits the autos as well.

20141221_171628 by dresselhausfc, on Flickr

20141221_171628 by dresselhausfc, on Flickr

20141221_171649 by dresselhausfc, on Flickr

20141221_171649 by dresselhausfc, on Flickr

Here it is next to a factory transmission mount.

20141221_171946 by dresselhausfc, on Flickr

20141221_171946 by dresselhausfc, on Flickr

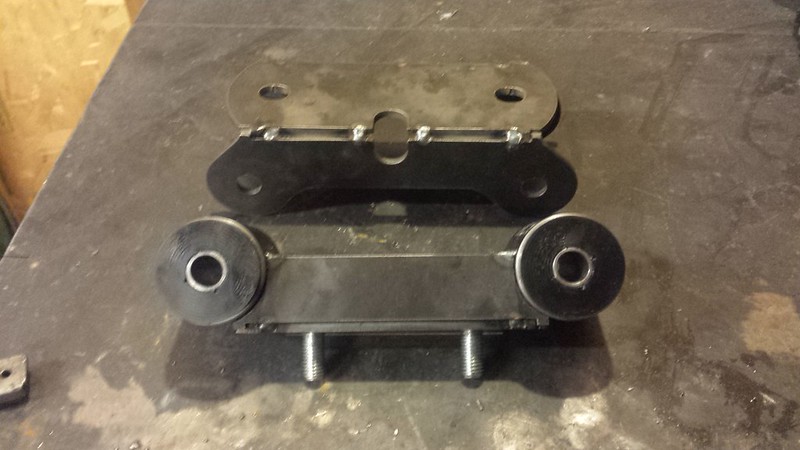

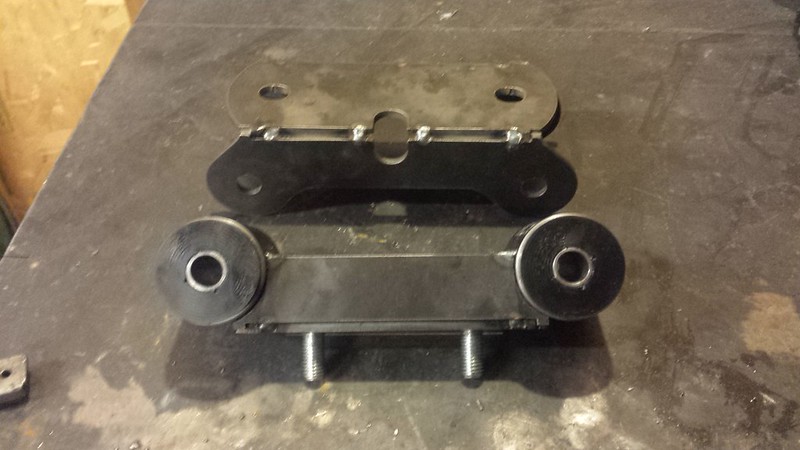

Here are the two parts of it.

20141221_172036 by dresselhausfc, on Flickr

20141221_172036 by dresselhausfc, on Flickr

Here it is attached to a 5speed tailhousing like what my truck has in it. Going to test fit it with an auto in a 95 ranger as my parents have one to make sure it fits the autos as well.

20141221_171628 by dresselhausfc, on Flickr

20141221_171628 by dresselhausfc, on Flickr 20141221_171649 by dresselhausfc, on Flickr

20141221_171649 by dresselhausfc, on FlickrHere it is next to a factory transmission mount.

20141221_171946 by dresselhausfc, on Flickr

20141221_171946 by dresselhausfc, on FlickrHere are the two parts of it.

20141221_172036 by dresselhausfc, on Flickr

20141221_172036 by dresselhausfc, on Flickr