-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

RockRangerII Refresh

- Thread starter RockRanger

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Looks like the fuel pump was going out. Put a new pump, filter, and relay in and seems to be working now.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Jealous that my wife has a gauge on her York On Board Air system decided I needed one. My dash is starting to get a bit full so looking around I decided the perfect spot was where the electric shift 4x4 switches would be. I pulled the dash apart and pulled to vent and came up with a game plan. First I cut the back piece that will clip in where the 4x4 control piece clipped in.

20160705_120208 by Matthew Dresselhaus, on Flickr

20160705_120208 by Matthew Dresselhaus, on Flickr

Next tapped the 4 holes to match some button head screws I have. Here you can see the two tabs on top and bottom that the original piece clips into. Mine clips into the same holes.

20160705_131141 by Matthew Dresselhaus, on Flickr

20160705_131141 by Matthew Dresselhaus, on Flickr

20160705_131135 by Matthew Dresselhaus, on Flickr

20160705_131135 by Matthew Dresselhaus, on Flickr

Then I made a small plate that would secure a gauge I had laying around to the front plate. I added a few tack welds to hold it all together.

20160705_120215 by Matthew Dresselhaus, on Flickr

20160705_120215 by Matthew Dresselhaus, on Flickr

20160705_120224 by Matthew Dresselhaus, on Flickr

20160705_120224 by Matthew Dresselhaus, on Flickr

Here is the panel all mounted up and reading how much pressure is in the system. I have something else in mind for the left side of the panel.

20160705_133204 by Matthew Dresselhaus, on Flickr

20160705_133204 by Matthew Dresselhaus, on Flickr

20160705_120208 by Matthew Dresselhaus, on Flickr

20160705_120208 by Matthew Dresselhaus, on FlickrNext tapped the 4 holes to match some button head screws I have. Here you can see the two tabs on top and bottom that the original piece clips into. Mine clips into the same holes.

20160705_131141 by Matthew Dresselhaus, on Flickr

20160705_131141 by Matthew Dresselhaus, on Flickr 20160705_131135 by Matthew Dresselhaus, on Flickr

20160705_131135 by Matthew Dresselhaus, on FlickrThen I made a small plate that would secure a gauge I had laying around to the front plate. I added a few tack welds to hold it all together.

20160705_120215 by Matthew Dresselhaus, on Flickr

20160705_120215 by Matthew Dresselhaus, on Flickr 20160705_120224 by Matthew Dresselhaus, on Flickr

20160705_120224 by Matthew Dresselhaus, on FlickrHere is the panel all mounted up and reading how much pressure is in the system. I have something else in mind for the left side of the panel.

20160705_133204 by Matthew Dresselhaus, on Flickr

20160705_133204 by Matthew Dresselhaus, on Flickr- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

I fixed my truck not running issue with a new fuel pump, filter and relay. So far so good. I also spent 6 of 9 days in the local mountains wheeling.

First I ran up to Bald Mountain. Fun relaxing and did a few of the harder side obstacles. My 5 year old isn't much for taking pictures so this is the only one I got.

20160805_145203 by Matthew Dresselhaus, on Flickr

20160805_145203 by Matthew Dresselhaus, on Flickr

The next day we went to Red Lake again in my wife's Jeep with the family. No pictures here but was uneventful for us.

two days later I loaded up with my Dad as a passenger and we met a friend and ran Swamp Lake Trail. It is one of the harder trails in the local area. We took our time and did it over two days. The views we amazing the weather was perfect and the fishing wasn't bad either.

20160809_144446 by Matthew Dresselhaus, on Flickr

20160809_144446 by Matthew Dresselhaus, on Flickr

20160809_145426 by Matthew Dresselhaus, on Flickr

20160809_145426 by Matthew Dresselhaus, on Flickr

20160809_192524 by Matthew Dresselhaus, on Flickr

20160809_192524 by Matthew Dresselhaus, on Flickr

20160809_195022 by Matthew Dresselhaus, on Flickr

20160809_195022 by Matthew Dresselhaus, on Flickr

Came home for a few days and went for a day run to Coyote lake. The run to Coyote consists of going to Red lake then continuing onto Coyote. Once past Red the trail gets significantly harder. We were making good time and just about too the lake when I lost my steering. Got out to find a hiem on my panhard bar had broken. I had a spare in the truck with me so in short order we had the truck fixed and back on the trail.

20160813_121025 by Matthew Dresselhaus, on Flickr

20160813_121025 by Matthew Dresselhaus, on Flickr

20160813_172907 by Matthew Dresselhaus, on Flickr

20160813_172907 by Matthew Dresselhaus, on Flickr

20160813_172901 by Matthew Dresselhaus, on Flickr

20160813_172901 by Matthew Dresselhaus, on Flickr

20160813_145510 by Matthew Dresselhaus, on Flickr

20160813_145510 by Matthew Dresselhaus, on Flickr

20160813_145456 by Matthew Dresselhaus, on Flickr

20160813_145456 by Matthew Dresselhaus, on Flickr

First I ran up to Bald Mountain. Fun relaxing and did a few of the harder side obstacles. My 5 year old isn't much for taking pictures so this is the only one I got.

20160805_145203 by Matthew Dresselhaus, on Flickr

20160805_145203 by Matthew Dresselhaus, on FlickrThe next day we went to Red Lake again in my wife's Jeep with the family. No pictures here but was uneventful for us.

two days later I loaded up with my Dad as a passenger and we met a friend and ran Swamp Lake Trail. It is one of the harder trails in the local area. We took our time and did it over two days. The views we amazing the weather was perfect and the fishing wasn't bad either.

20160809_144446 by Matthew Dresselhaus, on Flickr

20160809_144446 by Matthew Dresselhaus, on Flickr 20160809_145426 by Matthew Dresselhaus, on Flickr

20160809_145426 by Matthew Dresselhaus, on Flickr 20160809_192524 by Matthew Dresselhaus, on Flickr

20160809_192524 by Matthew Dresselhaus, on Flickr 20160809_195022 by Matthew Dresselhaus, on Flickr

20160809_195022 by Matthew Dresselhaus, on FlickrCame home for a few days and went for a day run to Coyote lake. The run to Coyote consists of going to Red lake then continuing onto Coyote. Once past Red the trail gets significantly harder. We were making good time and just about too the lake when I lost my steering. Got out to find a hiem on my panhard bar had broken. I had a spare in the truck with me so in short order we had the truck fixed and back on the trail.

20160813_121025 by Matthew Dresselhaus, on Flickr

20160813_121025 by Matthew Dresselhaus, on Flickr 20160813_172907 by Matthew Dresselhaus, on Flickr

20160813_172907 by Matthew Dresselhaus, on Flickr 20160813_172901 by Matthew Dresselhaus, on Flickr

20160813_172901 by Matthew Dresselhaus, on Flickr 20160813_145510 by Matthew Dresselhaus, on Flickr

20160813_145510 by Matthew Dresselhaus, on Flickr 20160813_145456 by Matthew Dresselhaus, on Flickr

20160813_145456 by Matthew Dresselhaus, on Flickr- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Axle side heim joint off my Panhard bar. Broke right at the end of the bung. Between the bung and Jam nut. The joint still feels tight and has full motion. We were able to unthread the jam nut and reuse it. We were able to back the broken piece of the heim out of the bung using a screwdriver and taping it at an angle. New one threaded right in. Not sure if it was just a material failure or what. Going to pickup another joint as a spare and look at redesigning it using larger joints.

Kirby N.

Elite Explorer

- Joined

- February 6, 2001

- Messages

- 2,654

- Reaction score

- 465

- City, State

- Colorado Springs, CO

- Year, Model & Trim Level

- 1991 Ranger

Dude! Good thing it didn't break on the highway! I suggest using something other than a heim. The only reason to use a heim is because of strength. They wear and get loose especially in an application that sees constant weather. I had to swap them once a year in my exploder. I am using ballistic joints in my ranger trackbar.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

I am looking into other options. I would like to stay with 2 inch width joints with a 5/8 or larger bolt. That way I can reuse my frame and axle mounts.

Kirby N.

Elite Explorer

- Joined

- February 6, 2001

- Messages

- 2,654

- Reaction score

- 465

- City, State

- Colorado Springs, CO

- Year, Model & Trim Level

- 1991 Ranger

Ruff stuff makes bushings to neck down bolt holes to smaller sizes. I used them on a pre made track bar mount to change the hole size. That might open up some possibilities for you.

http://www.ruffstuffspecialties.com...roduct_Code=FIXIT&Category_Code=reinforplates

http://www.ruffstuffspecialties.com...roduct_Code=FIXIT&Category_Code=reinforplates

- Joined

- November 29, 2000

- Messages

- 10,627

- Reaction score

- 5,020

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

Looks like you are making full use of the Ranger. I took my Explorer for a 20 mile drive around town last week.......

I went out and checked all of my heims and they are tight, with no wear showing. Having that one fail on you makes me nervous as they are on my steering, panhard and radius arms.

I went out and checked all of my heims and they are tight, with no wear showing. Having that one fail on you makes me nervous as they are on my steering, panhard and radius arms.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

It was an old Midwest control heim. When I got it there weren't the choices that are available today. It is a 3/4 inch joint. It looks like I can get some ruff stuff 7/8 heims and bungs and cut my bungs off and weld them on. They are a lot stronger then what I broke. I have a week or two to figure out what I want to do.

- Joined

- November 29, 2000

- Messages

- 10,627

- Reaction score

- 5,020

- Location

- USA

- City, State

- San Diego, PRofK

- Year, Model & Trim Level

- 1994 XLT

Do you have heims at both ends of your panhard? I have a stock Ford type poly bushing on the axle side and a heim on the frame side.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Both ends are heim. I have a slight bend on the axle end to help clear the engine crossmember at full compression. That may or may not have helped caused it to break.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

I also got sick of using an adjustable wrench to tighten the jam nuts on my links so I cut a crows foot on my plasma table for my 1/2" ratchets.

20160815_165636 by Matthew Dresselhaus, on Flickr

20160815_165636 by Matthew Dresselhaus, on Flickr

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Not many changes to the truck lately but it did roll 200k yesterday on my way home from Coyote Lake wheeling trip. I also was able to get one of the rare saginaw pumps that bolts to the power steering pump. It has a few clearance issues with my york that I am currently working thru before I get it all mounted. I also ordered the two core radiator to hopefully solve my getting warm issues on long uphill pulls.

20160902_160608 by Matthew Dresselhaus, on Flickr

20160902_160608 by Matthew Dresselhaus, on Flickr

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

Went wheeling to Mirror Lake this weekend. While it is rather short at just over a mile long it is has the hardest non bypassable section of the local trails. we didn't have much trouble on the trail When we got to the lake we ate lunch and did some fishing. My daughter and a friends daughter caught 8 fish in just over an hour. Here was the haul.

20160903_135404 by Matthew Dresselhaus, on Flickr

20160903_135404 by Matthew Dresselhaus, on Flickr

I also bought a duel core radiator to swap in my truck. The truck gets a bit warmer then I like on some of the long hills to the trails. Here it is next to the single core I removed.

20160904_165555 by Matthew Dresselhaus, on Flickr

20160904_165555 by Matthew Dresselhaus, on Flickr

When swapping the radiator you need to swap the fan shroud and the lower radiator hose as well. The fan shroud came out of a first gen explorer at pick and pull. The single core shroud measures roughly 4.5" deep. The duel core is 3" The lower hose I purchased new is for an automatic ranger. I think the lower I took off was the original hose.

20160904_165646 by Matthew Dresselhaus, on Flickr

20160904_165646 by Matthew Dresselhaus, on Flickr

20160904_164929 by Matthew Dresselhaus, on Flickr

20160904_164929 by Matthew Dresselhaus, on Flickr

Now to finish my steering pump swap and I can fire it up.

20160903_135404 by Matthew Dresselhaus, on Flickr

20160903_135404 by Matthew Dresselhaus, on FlickrI also bought a duel core radiator to swap in my truck. The truck gets a bit warmer then I like on some of the long hills to the trails. Here it is next to the single core I removed.

20160904_165555 by Matthew Dresselhaus, on Flickr

20160904_165555 by Matthew Dresselhaus, on FlickrWhen swapping the radiator you need to swap the fan shroud and the lower radiator hose as well. The fan shroud came out of a first gen explorer at pick and pull. The single core shroud measures roughly 4.5" deep. The duel core is 3" The lower hose I purchased new is for an automatic ranger. I think the lower I took off was the original hose.

20160904_165646 by Matthew Dresselhaus, on Flickr

20160904_165646 by Matthew Dresselhaus, on Flickr 20160904_164929 by Matthew Dresselhaus, on Flickr

20160904_164929 by Matthew Dresselhaus, on FlickrNow to finish my steering pump swap and I can fire it up.

- Joined

- January 14, 2001

- Messages

- 6,187

- Reaction score

- 292

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

To install the rare saginaw pump like many things it couldn't go smoothly. Fist thing was that the fill neck would end up directly under my York Compressor. Fortunately the housing is steel. So a few cuts with a cut off wheel I took a pie shape piece out so I could get fluid in the pump.

20160829_181305 by Matthew Dresselhaus, on Flickr

20160829_181305 by Matthew Dresselhaus, on Flickr

20160829_181254 by Matthew Dresselhaus, on Flickr

20160829_181254 by Matthew Dresselhaus, on Flickr

After bending it over and welding it back together with some ugly welds I put it back together. I covered the welds with rtv in case I had any pin holes to stop any leaks. With my pump I got the engine bracket so I didn't have to do any clearancing on the bracket. When I went to put the pulley back on the pump the center hole was stripped. So I had to redrill and tap it so I could get the pulley back on. Then I got it bolted back into the truck. I also converted two of the the bolts holding my york to studs.

20160906_134145 by Matthew Dresselhaus, on Flickr

20160906_134145 by Matthew Dresselhaus, on Flickr

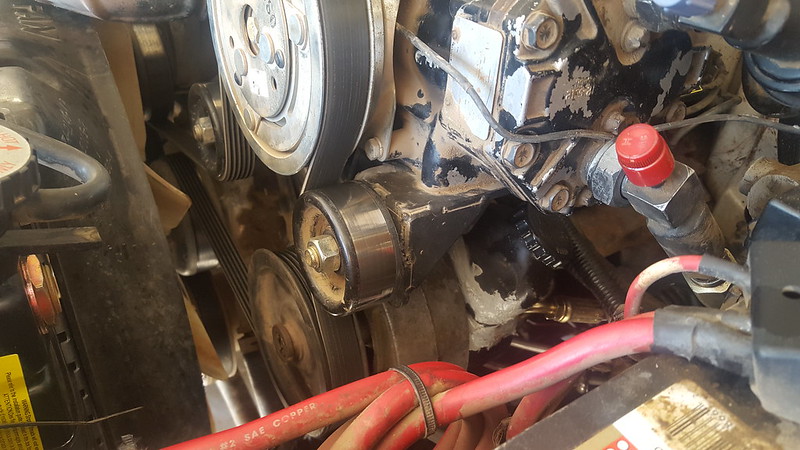

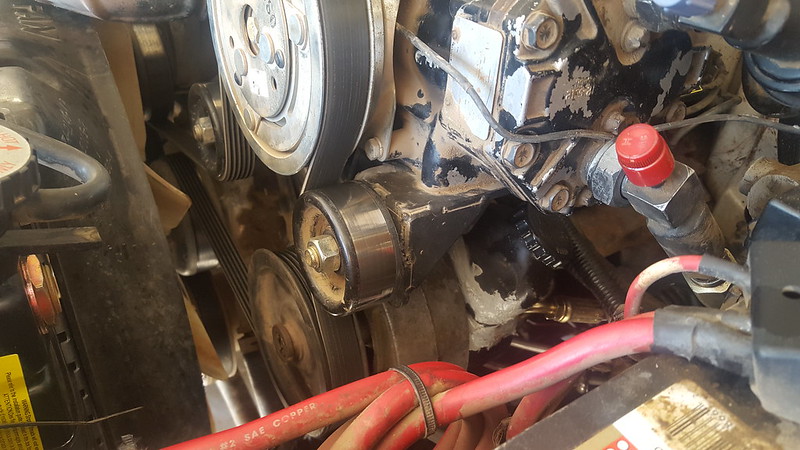

The shaft of the new pump sits higher which made the pump pulley hit one of my York idler pulleys. Fortunately I was able to drill a new hole and re locate the idler and reuse the same belt. Here is everything bolted back up. Notice how if I wouldn't have modified the filler neck it wouldn't have let me get fluid in around my York.

20160907_095631 by Matthew Dresselhaus, on Flickr

20160907_095631 by Matthew Dresselhaus, on Flickr

Then it came time to hook up the fluid lines. The low pressure side went right on. When it came time to do the High Pressure side I ran into trouble. The ranger line is Metric and the pump end is SAE. On my pump they were also different types of fittings as well. So the line would thread in, it would not seal. So I took it back apart and went to a few different hydraulic shops and finally found one that could make the line I needed. He took the hard metal ranger line coming out of the box and then crimped new fittings and hoses to it. Then put the correct end for the pump on the other. I put it all in and fired up the truck. Turned the wheel slightly and blew fluid all over the garage truck and motor. I missed tightening one of the fittings. Once that fitting was tightened no more leaks. Here you can kind of see the new line I had made.

20160907_095646 by Matthew Dresselhaus, on Flickr

20160907_095646 by Matthew Dresselhaus, on Flickr

20160907_095652 by Matthew Dresselhaus, on Flickr

20160907_095652 by Matthew Dresselhaus, on Flickr

So far I have only pulled it in and out of the garage to clean up the mess I made. It is much quieter then the old pump and is a good starting point when I eventually add ram assist to the steering.

20160829_181305 by Matthew Dresselhaus, on Flickr

20160829_181305 by Matthew Dresselhaus, on Flickr 20160829_181254 by Matthew Dresselhaus, on Flickr

20160829_181254 by Matthew Dresselhaus, on FlickrAfter bending it over and welding it back together with some ugly welds I put it back together. I covered the welds with rtv in case I had any pin holes to stop any leaks. With my pump I got the engine bracket so I didn't have to do any clearancing on the bracket. When I went to put the pulley back on the pump the center hole was stripped. So I had to redrill and tap it so I could get the pulley back on. Then I got it bolted back into the truck. I also converted two of the the bolts holding my york to studs.

20160906_134145 by Matthew Dresselhaus, on Flickr

20160906_134145 by Matthew Dresselhaus, on FlickrThe shaft of the new pump sits higher which made the pump pulley hit one of my York idler pulleys. Fortunately I was able to drill a new hole and re locate the idler and reuse the same belt. Here is everything bolted back up. Notice how if I wouldn't have modified the filler neck it wouldn't have let me get fluid in around my York.

20160907_095631 by Matthew Dresselhaus, on Flickr

20160907_095631 by Matthew Dresselhaus, on FlickrThen it came time to hook up the fluid lines. The low pressure side went right on. When it came time to do the High Pressure side I ran into trouble. The ranger line is Metric and the pump end is SAE. On my pump they were also different types of fittings as well. So the line would thread in, it would not seal. So I took it back apart and went to a few different hydraulic shops and finally found one that could make the line I needed. He took the hard metal ranger line coming out of the box and then crimped new fittings and hoses to it. Then put the correct end for the pump on the other. I put it all in and fired up the truck. Turned the wheel slightly and blew fluid all over the garage truck and motor. I missed tightening one of the fittings. Once that fitting was tightened no more leaks. Here you can kind of see the new line I had made.

20160907_095646 by Matthew Dresselhaus, on Flickr

20160907_095646 by Matthew Dresselhaus, on Flickr 20160907_095652 by Matthew Dresselhaus, on Flickr

20160907_095652 by Matthew Dresselhaus, on FlickrSo far I have only pulled it in and out of the garage to clean up the mess I made. It is much quieter then the old pump and is a good starting point when I eventually add ram assist to the steering.

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

Similar threads

- Replies

- 642

- Views

- 112,016

- Replies

- 19

- Views

- 1,211

- Replies

- 30

- Views

- 6,221

- Replies

- 3

- Views

- 373