turboexplorer

Elite Explorer

- Joined

- August 23, 2008

- Messages

- 1,922

- Reaction score

- 41

- City, State

- Eagle Mountain, UT

- Year, Model & Trim Level

- 98' XLT 5.0L 4X4

- Callsign

- Turbo

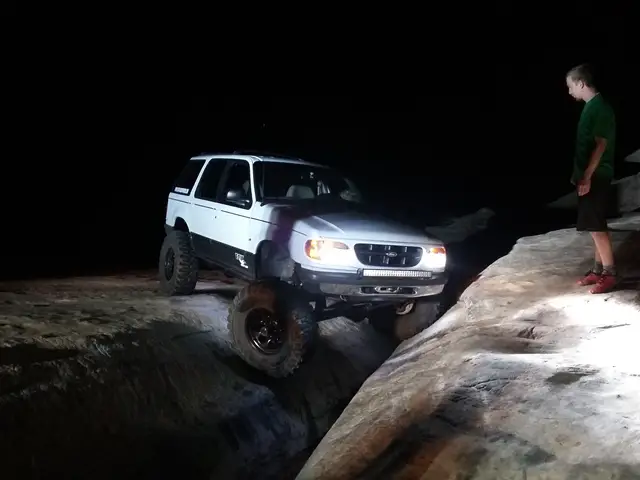

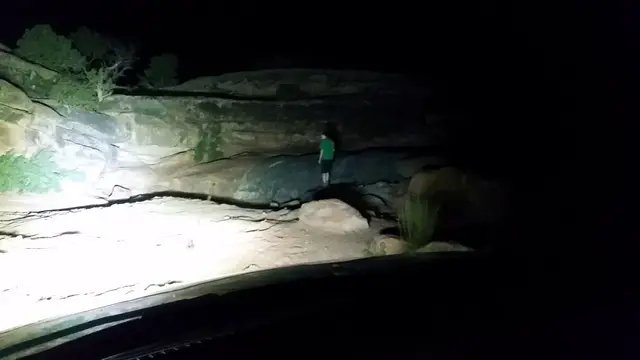

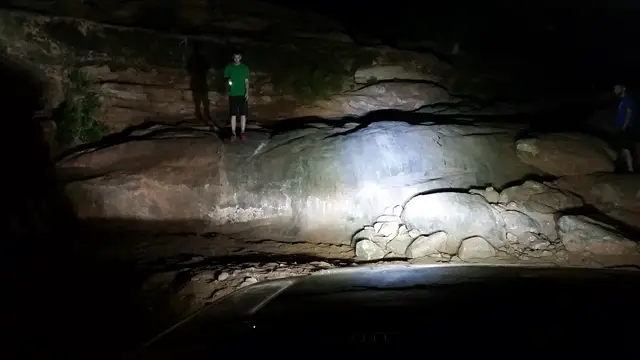

Here is some additional pictures of Golden Spike and Gold Bar Rim.

I am wondering now that you have this all under your belt, would you do anything different related to the coil overs?

I see that you settled on 60/90 for the valving. Do you still like this or would you tweak it?

total spring rate of ???/in (I know, its back there somewhere). Would you change the spring rates?

You went with 14" travel. Would you still?

Anything else you can think of that would help in selecting the shock would be appreciated.

In the minimal amount of research I have done it seems like Fox is paying attention to all the right details. The same shocks you bought are still right at $400 each. Seems like a no-brainer to me.

What valving are you going to aim for in your next stab at it?

You mentioned several times that you were considering some air bumps. Did that ever happen? I am probably going to do them at the same time as the coilovers.

. Not sure if I am currently going fast enough to notice rebound changes, currently doesn't feel like it is packing but a video may tell in slow motion. But again a complete novice and not sure what I am looking for. General idea but the rest is from the few changes I have made so far. I do have full seal rebuild sets for them this next time they come apart.

. Not sure if I am currently going fast enough to notice rebound changes, currently doesn't feel like it is packing but a video may tell in slow motion. But again a complete novice and not sure what I am looking for. General idea but the rest is from the few changes I have made so far. I do have full seal rebuild sets for them this next time they come apart. .

.

It wasn't from the land it was from going flat to up the kicker. Lucky just a light crack so drove home with no issues.

It wasn't from the land it was from going flat to up the kicker. Lucky just a light crack so drove home with no issues.  Oops...

Oops...  Just gives me an excuse to put on the FOX bumps

Just gives me an excuse to put on the FOX bumps Would a stock stamped steel pan work for you? You can have the one off my truck.

. So no idea, not sure if from fordparts.com is different from what the dealers can get????

. So no idea, not sure if from fordparts.com is different from what the dealers can get????