gsbarry

Well-Known Member

- Joined

- August 6, 2008

- Messages

- 156

- Reaction score

- 12

- City, State

- Houston, TX

- Year, Model & Trim Level

- Stock 97 4.0 EB SOHC

Input Sprag

JK, is this the part you are referring to? (I'm obviously a noob w/ transmissions)

What do you usually see in terms of damage to the input sprag? Assuming I have the right part, ATSG manual says to inspect for:

- cracks on the roller cage

- wear on the roller clutch

- the press fit of the clutch to the center shaft

- excessive wear or damage to rollers and springs

- bent or damaged spring retainers within the roller cage

I've been going through the ATSG manual, and it is pretty thorough without being overwhelming. I'll perform the line pressure test again before i start the removal process, just to see if there's a difference, though I doubt there will be.

I did notice that the manual only seems to diagnose the WOT portion of the test by stall speed (spec is 2400-2800) rather than pressure - although I suppose the two are inversely related.

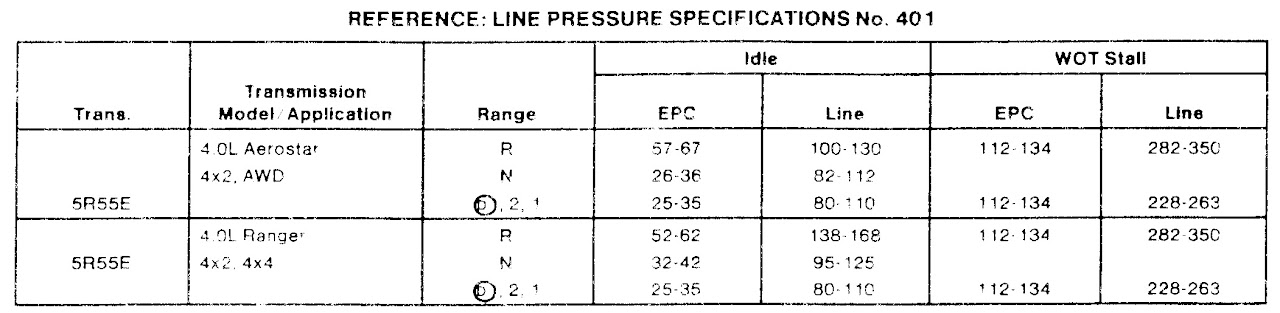

A high stall speed in D and/or OD indicates a failed forward clutch, and/or O/D one-way clutch (sprag). Note that although I do not have reverse engagement, the line pressure test at WOT in reverse was close to spec (probably user error). Here is the chart:

I'm feeling much more confident about a rebuild now that I have gone through the manual a bit - in addition to Glacier's A4 build. My next concern is limiting the expense for tools to do this job.

JK, is this the part you are referring to? (I'm obviously a noob w/ transmissions)

What do you usually see in terms of damage to the input sprag? Assuming I have the right part, ATSG manual says to inspect for:

- cracks on the roller cage

- wear on the roller clutch

- the press fit of the clutch to the center shaft

- excessive wear or damage to rollers and springs

- bent or damaged spring retainers within the roller cage

I've been going through the ATSG manual, and it is pretty thorough without being overwhelming. I'll perform the line pressure test again before i start the removal process, just to see if there's a difference, though I doubt there will be.

I did notice that the manual only seems to diagnose the WOT portion of the test by stall speed (spec is 2400-2800) rather than pressure - although I suppose the two are inversely related.

A high stall speed in D and/or OD indicates a failed forward clutch, and/or O/D one-way clutch (sprag). Note that although I do not have reverse engagement, the line pressure test at WOT in reverse was close to spec (probably user error). Here is the chart:

I'm feeling much more confident about a rebuild now that I have gone through the manual a bit - in addition to Glacier's A4 build. My next concern is limiting the expense for tools to do this job.