Creager

Explorer Addict

- Joined

- October 11, 2004

- Messages

- 2,780

- Reaction score

- 4

- City, State

- Charlotte, NC

- Year, Model & Trim Level

- '92 Sport 4x4

With all the questions recently like 'can I install my own gears?' or 'can I swap to an open carrier from a LSD unit?' I figured it was appropriate time to bring this up for everyone to benefit from.

I made this post in a thread a while back, in effort to enlighten the thread on what is involved in a gear install. All this information was written from my own gearing experience...

The pictures are from my personal collection of other gear installs around the net, most I used to learn from. The rest is for you to enjoy.

Things you will need:

Obviously the MAIN thing you are going to need to do this install is MONEY. In all honestly, I would have saved money having a shop doing this for me. But with the knowledge and experience I have earned, it’s something I could never have paid a shop to do. Not only that, my rear-ends will never go bad =)

I would say I spent around $1500 for this. Gears/Kits (4x4) = ~$700; Limited slip (USED TRUETRAC) = $300; and that’s just the toys, Tools = another $500. Plus you got to take in account the months of reading (write up's like this one), and all the visualization in my head it took to make this all work out. So now, after 10k miles, I can say I did a good job, or at least it still works haha.

1) A Locker, Limited slip, or your Stock carrier, which ever you plan on using. If you are using 4.56 gears or lower (numerically higher), you will need to notch the cross pin to clear the outer tip of the teeth on the ring gear. That is if you plan to use the stock carrier. If you plan on using a Truetrac (or any other 'full' locker/limited slip) and big gears (4.56+) you shouldn't need to do any modification, but in some instances you might need to grind down the very tip of the toe side on one or two teeth to clear the cross shaft (1/16th"-1/8")

2) Master install kit: Bearings, races, pinion seal (BCA is by far the best brand for this), new crush sleeve (probably want to go to Napa and get some extras), pinion nut (has to be a new one), pinion shims, carrier shim flanges, carrier shims.

3) Ring and Pinion Set: I recommend Motive Gear

4) Inlb Torque Wrench (10-50inlbs)

5) Ftlb Torque wrench

6) Threadlocker/Loktite

7) A good breaker bar

8) Jack and Jack stands

9) LOTS of brake cleaner (I went through 9 cans myself)

10) Like a quart or two of some cheap gear oil (80w-90) to clean the housing out with, and also (at least 5 quarts, 2.5 for break-in period, 2.5 for after break-in period) high-temp synthetic (I used Richmond Gear 70w-140). Synthetic is recommended if you plan on using any ratio larger then 4.33. Synthetic gear oil also has friction modifier added into the mix, adding more would actually be detrimental to a limited slip. Also a tube/sprayCan of lithium grease is good to pre-lube your bearings with, more on this later.

11) A Dial Indicator

12) Magnetic Base for the dial indicator

13) Dial calipers

14) Bearing puller (if you plan on pulling the bearings off the carrier and pinion yourself)

15) Bearing press (if you plan on pressing the bearings off the carrier and pinion yourself, do not use a hammer, do not use heat/cold to try and slip it on, all those methods are just asking for something to go wrong, and will piss you off... use a press.

16) Slide hammer (if you plan on removing/replacing your wheel bearings)

17) Wide variety of sockets (mainly Metric, you will need a 1 1/8" or 1 1/4" SAE for the pinion nut

18) Drain pan for old gear oil (Wider is better... always)

19) 24oz ball peen hammer

20) Rubber mallet

Important Specs:

Before you start, get your new ring gear pressed on to your new carrier (locker, limited slip). It’s not very common that a gear (new or used) will just slip on the carrier. I could get 7 of the 10 ring gear bolts in, but the last 3 wouldn’t catch. I fixed this by baking the ring gear in the oven for 3 hours at 300 degrees F. I also put my Truetrac (carrier) in the freezer during this time. Using this process works great, in fact the ring gear slipped right on the carrier, no effort needed what so ever.

Don’t try and Force the ring gear on too much. If you beat at it for too long the gear can warp. Although I would imagine it being somewhat difficult, it can happen. Once you get it on snug with all 10 bolts. Torque the bolts down to 77ftlbs with Thread locker. Do this in a star/cross pattern. Go from one bolt, to another bolt (directly or not) across from it; basically what ever you can do that’s not in a circle pattern. Make sure to do this with graduating intervals. For example, torque them to 25ftlbs first, then 35ftlbs... work your way up to 77ftlbs

There are 4 basic measurements you need to get.

1) Pinion Depth

2) Backlash

3) Pinion Bearing preload

4) Carrier bearing preload

I would recommend removing the entire axle (ford 8.8) from underneath the car. Especially if this is your first time doing gears. It’s tighter then a 400lb man's underpants underneath there, and that carrier is not exactly light; approximately 30lbs. Man-handling a 30lb object underneath a car is probably bad for you in one way or another (unless you got a lift in your garage), but at least it’s not a transmission.

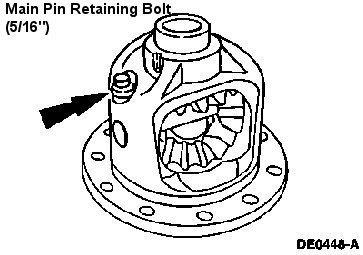

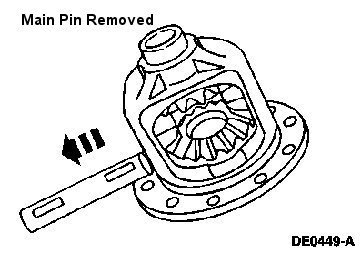

Start by removing the differential cover. Make sure you got some kind of pan underneath the axle; gear oil is going to go everywhere. Once you get this far, spin the carrier around until you see the Cross shaft bolt shown here...

I forget the size of this bolt, but it was quite small; I believe it was actually one of the smallest box wrenches I had! (8mm?) Be careful on this little sucker, too often do we just get in the rhythm of things and forget to take our time and 'feel' what the metal is trying to tell us. Too often does this sucker BREAK! And isn’t easy removing it! What I do to keep myself from getting in this situation, is hit that bolt up with some PBlaster or WD-40. After about 5-10 minutes of letting the penetrate do its job, I bust out the ol' MAPP Gas (20 bucks at most auto parts stores) and I heat the carrier around the bolt. DONT heat the bolt up directly! That should be enough to get that sucker out gracefully. This is what you are trying to accomplish... with the Cross Shaft removed.

With the cross shaft removed the C-Clip port should be in view, Push one of the axles inward (from the side of the axle), which will reveal the c-clip, remove it. Use needle nosed pliers (or just your hands) to pull the C-clips out. Once the c-clips are removed the axle shafts can be pulled. When you go to pull out the axle shafts, be careful not to put too much stress the bearing seal at the end of the axle tube. Do this for both sides.

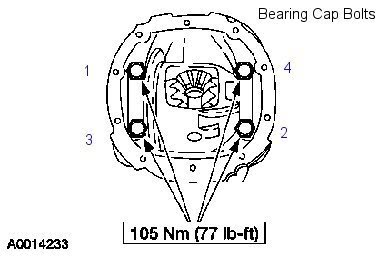

Remove the four big bolts that hold the carrier bearing caps on (shown below), then try and pull on the carrier/ring gear, to where it will pop out. If it’s too tight to be tugged out, a crow-bar to peal out the carrier. You can pry against ring gear bolts on the backside of the carrier. If you tug right on its sweet spot, you can get the carrier all the way out in just one tug, on one side... if you jar up the carrier (i mean, sort of jamming it side-to-side, which you will probably do your first couple times) you will have to pry from the opposite side (which has no bolts to pry on ). Use a piece of wood to wedge the crow bar on, so you don’t ding up the axle housing. Try and not ding up the carrier too much, because it’s easy to make junk out it.

). Use a piece of wood to wedge the crow bar on, so you don’t ding up the axle housing. Try and not ding up the carrier too much, because it’s easy to make junk out it.

Make sure mark the bearing caps between right and left. Those caps are machined to match the housing and do not interchange. If you mix them up you can compare the texture of the machined surface on the cap to the texture in the house. Take notice of the tapered sides of the caps, this will contrast to the tapering on the housing

In the materials list, I mentioned using lithium grease to pre-lube all your bearings with. Lithium grease mixes with gear oil very nicely; making one nice interesting looking pile of grease... it will not hurt your bearings or housing. The lithium grease will stay in the bearings for the first hundred miles and will keep them from breaking down during the all so crucial break-in period. Pack in the lithium grease like you would with heavy grease and a common wheel bearing. Works like a charm.

Now you want to measure the gear run out. This is not highly important and you cannot do it with the ABS ring pressed onto your carrier. The gear back face run out is obtained by pointing the dial indicator at the back of the ring gear (smooth side, not the teeth side). Rotate the driveshaft (pinion flange) and record the amount the needle moves. The maximum run out is 0.003”

Setting up Backlash

Now you want to measure the backlash by putting the dial indicator on the very edge of a tooth on the ring gear, you want the indicator to be perpendicular to the edge of the tooth as you possibly can. If you look closely, some gear manufacturers make a little tapered edge on this section of the teeth, using this area makes pointing the dial indicator very accurate.

The backlash is the amount of slop in between the ring gear and the pinion; you are measuring that distance. (.008"-.015") is the amount you want. You are going to move the carrier left and right by using the shims in your install kit. The stock shims (for me) were .255" on the left and .280 on the right. Use shim flanges in your install kit to put your shims in; the flanges are like .210" each. I started with a .060 shim in each side to start off. If your backlash is tight (or the ring gear is too close to the pinion gear) take the amount of shims on the left and add it to the right; vice versa for the right. You want to keep this balance so your backlash stays consistent. Make sure you torque the bearing caps to 77ftlbs before checking your pattern...

Your Pinion Depth

Before you start setting up the pinion depth, I recommend removing the existing inner pinion bearing; using a die grinder, grind down the inside diameter (about .001) on the bearing. This will allow the bearing to slip on and off the pinion with very little effort. This will make the process much easier. Just remember when you are done to get a new bearing pressed on there.

The pinion depth is the next measurement you need to look at. Put some gear marking compound on a couple teeth and turn the pinion to get a little pattern.

You don't need to use a crush sleeve each time you remove the pinion to change shims. It can make things tedious for you and possibly give you a false preload, but most of all leaving the sleeve out teaches you what 16inlbs should feel like. As long the torque it takes to turn the pinion is the same as when you go to set up your final assembly with a crush sleeve, pinion depth will be the same. Just make sure to check it, when you are trying to get a feel for it.

In general, when you are setting up gears you are mainly trying to measure from the face to the flank of the tooth, a perfect heel to toe pattern usually impractical. The reason i say this is because all housings are different. My 8.8 would center heel to toe perfectly, dead center. My dana 35 on the otherhand would jump from extreme toe, to being somewhat off-center towards the heel, when just a simple .002" shim was installed. It was practically impossible for me to get it DEAD center, but its very close. After that i could use .005" shims, and the depth would bearly change. This was due to way the housing was machined, the pinion bore may be slightly offset, crooked, or something, to the axle centerline, (imaginary line that runs down the direct middle of the axle tubes.)

If your pattern seems way too close to the toe, then subtract some shim thickness from your pinion shim. If you are closer to the heel, Add shims. Usually (especially in smaller gear jumps like 3.55 to 4.10) the stock pinion shim should be perfect. My stock pinion shim was a good starting point; with a Jump from 3.27 to 4.56 I was barely too close to the toe for my liking. I dropped the pinion shim by -.002 and it was perfect from there. Remove the carrier and add/subtract the amount in shims on your stock pinion shim to get your pattern

Check your pattern again, and if you like what you got then you basically done! The chart below, taken from the Yukon gear manual, should be able to help you determine the pattern. The pattern is going to be difficult to read on the coast side (a.k.a ghost side) during trial assemblies, or until you adjust the preload on the pinion and carrier bearings. After the preloads' have been set the pattern should be nice and defined. There should be a nice shaped oval centered between face and flank on the drive side, and on the ghost side there should be a nice swoop across the back of the gear, again centered face to flank.

I stole this little snit bit from the Yukon gear install manual. This should help you determine if your gear pattern is correct.

Pinion bearing preload.

You will need a Good breaker bar here. Also an inlb torque wrench that can read as low as 10 inlbs. You probably will want some extra crush sleeves and pinion seals too... Assemble your pinion... shims, inner bearing, crush sleeve, outer bearing, oil slinger, oil seal, pinion flange then finally the OLD pinion nut from your stock gear set. You want to use the old nut to CRUSH the crush sleeve, ill elaborate on this some more in a second...

Start cranking that Nut, it will take a good 200ftlbs to crush that crush sleeve to specification. An impact may only get you so far, but even the ones with like 550ftlb burst fire won’t get that nut as tight as it needs to go. What you are trying to do it shrink that crush sleeve until the bearings are pressed up against the races. Every Quarter turn you put on the pinion nut, tap the pinion with a soft (rubber) hammer. Then use your inlb torque wrench to check the amount of drag that’s on the pinion.

When your preload is close (somewhere like 2-5inlbs), remove the old nut, and start over with the new one. Although it will be MUCH easier the second time around, because the crush sleeve is already crushed. Remember to put some lock-tit on there. The reason its good practice to crush the sleeve with the old nut, is because the threads on the pinion nut taper. The threads on the old nut are worn and will loosen up easily, especially with new bearings. There is some debate on this, and ill go by what I’ve always been taught... and that’s to not re-use the old nut.

It should take 16-29inlbs (on new bearings) to make the pinion move or in other words to correctly preload the pinion bearings. If it goes above that then you have to start over with a new crush sleeve.

It will take about 2 full turns till you close to specification. That’s not exact, you need to check every quarter turn, but once it gets close it happens very quickly. When you feel drag on the pinion, and maybe you are at 4 or 5 inlbs, only a very slight turn is needed; very slight.

Carrier bearing preload

Once your pinion is set, reinstall your carrier. Use the shims you decided had the correct backlash and add .005-.007 to each side to preload the carrier bearings. At this point, if your backlash is close but you would like it tighter/looser, then you can add more to one side to balance it out.

Its going to be a very tight fit, but keep in mind it’s harder to over preload the carrier bearings then to not. Although not impossible, it’s rare because you got to be freggin He-man to press in that tight of a fit. Use a rubber hammer to smack in the carrier. Torque down your bearing caps to 77ftlbs and check your pattern again, just for giggles...

If your pattern is correct, and you feel comfortable with your preloads, then get that sucker back under the truck! You're done! Well...

...almost

The Break-In Period

This is the most crucial part of the gear install.

Gears have to be broken in properly or they will fail within the first 500 miles of installation. Most gear sets fail because people neglect that they need to break in the gears.

It’s pretty easy. Drive for no more then 10-30 minutes at a time. Make sure you give your differential adequate time to cool after driving (at least an hour).

Drive normally. You should be alright gassing the petal a little bit, just put any extreme stress on the differential until the 500 break-in period has expired.

Make sure you set your Trip meter after your install, so you know when the 500 mile mark comes. When it does, change the gear oil. You should take notice of any metal shavings and debris in the gear oil. If anything seems a bit excessive then closely examine the (with gear marking compound) gears and make sure they are meshing properly. You never know, you might have gotten some debris in the shims and gotten a false preload setting?

Links to some other great gear manuals

Yukon Gear installation guide

Corral .net gear install write up - VERY EXPLAINATIONAL!

Randy's Ring and Pinion

AccuAutoParts - Tech help

I like the Accu guys, because they have a Tech email! You can email them with any gear install question, and they respond within 24 hours.

Picture Sources, as well as some more great gearing info writen by a fellow EF member: metroplex.

http://www.redpulsar.us/~coldfusion/TT.html

http://www.redpulsar.us/~coldfusion/tlok.html

I made this post in a thread a while back, in effort to enlighten the thread on what is involved in a gear install. All this information was written from my own gearing experience...

The pictures are from my personal collection of other gear installs around the net, most I used to learn from. The rest is for you to enjoy.

Things you will need:

Obviously the MAIN thing you are going to need to do this install is MONEY. In all honestly, I would have saved money having a shop doing this for me. But with the knowledge and experience I have earned, it’s something I could never have paid a shop to do. Not only that, my rear-ends will never go bad =)

I would say I spent around $1500 for this. Gears/Kits (4x4) = ~$700; Limited slip (USED TRUETRAC) = $300; and that’s just the toys, Tools = another $500. Plus you got to take in account the months of reading (write up's like this one), and all the visualization in my head it took to make this all work out. So now, after 10k miles, I can say I did a good job, or at least it still works haha.

1) A Locker, Limited slip, or your Stock carrier, which ever you plan on using. If you are using 4.56 gears or lower (numerically higher), you will need to notch the cross pin to clear the outer tip of the teeth on the ring gear. That is if you plan to use the stock carrier. If you plan on using a Truetrac (or any other 'full' locker/limited slip) and big gears (4.56+) you shouldn't need to do any modification, but in some instances you might need to grind down the very tip of the toe side on one or two teeth to clear the cross shaft (1/16th"-1/8")

2) Master install kit: Bearings, races, pinion seal (BCA is by far the best brand for this), new crush sleeve (probably want to go to Napa and get some extras), pinion nut (has to be a new one), pinion shims, carrier shim flanges, carrier shims.

3) Ring and Pinion Set: I recommend Motive Gear

4) Inlb Torque Wrench (10-50inlbs)

5) Ftlb Torque wrench

6) Threadlocker/Loktite

7) A good breaker bar

8) Jack and Jack stands

9) LOTS of brake cleaner (I went through 9 cans myself)

10) Like a quart or two of some cheap gear oil (80w-90) to clean the housing out with, and also (at least 5 quarts, 2.5 for break-in period, 2.5 for after break-in period) high-temp synthetic (I used Richmond Gear 70w-140). Synthetic is recommended if you plan on using any ratio larger then 4.33. Synthetic gear oil also has friction modifier added into the mix, adding more would actually be detrimental to a limited slip. Also a tube/sprayCan of lithium grease is good to pre-lube your bearings with, more on this later.

11) A Dial Indicator

12) Magnetic Base for the dial indicator

13) Dial calipers

14) Bearing puller (if you plan on pulling the bearings off the carrier and pinion yourself)

15) Bearing press (if you plan on pressing the bearings off the carrier and pinion yourself, do not use a hammer, do not use heat/cold to try and slip it on, all those methods are just asking for something to go wrong, and will piss you off... use a press.

16) Slide hammer (if you plan on removing/replacing your wheel bearings)

17) Wide variety of sockets (mainly Metric, you will need a 1 1/8" or 1 1/4" SAE for the pinion nut

18) Drain pan for old gear oil (Wider is better... always)

19) 24oz ball peen hammer

20) Rubber mallet

Important Specs:

Before you start, get your new ring gear pressed on to your new carrier (locker, limited slip). It’s not very common that a gear (new or used) will just slip on the carrier. I could get 7 of the 10 ring gear bolts in, but the last 3 wouldn’t catch. I fixed this by baking the ring gear in the oven for 3 hours at 300 degrees F. I also put my Truetrac (carrier) in the freezer during this time. Using this process works great, in fact the ring gear slipped right on the carrier, no effort needed what so ever.

Don’t try and Force the ring gear on too much. If you beat at it for too long the gear can warp. Although I would imagine it being somewhat difficult, it can happen. Once you get it on snug with all 10 bolts. Torque the bolts down to 77ftlbs with Thread locker. Do this in a star/cross pattern. Go from one bolt, to another bolt (directly or not) across from it; basically what ever you can do that’s not in a circle pattern. Make sure to do this with graduating intervals. For example, torque them to 25ftlbs first, then 35ftlbs... work your way up to 77ftlbs

There are 4 basic measurements you need to get.

1) Pinion Depth

2) Backlash

3) Pinion Bearing preload

4) Carrier bearing preload

I would recommend removing the entire axle (ford 8.8) from underneath the car. Especially if this is your first time doing gears. It’s tighter then a 400lb man's underpants underneath there, and that carrier is not exactly light; approximately 30lbs. Man-handling a 30lb object underneath a car is probably bad for you in one way or another (unless you got a lift in your garage), but at least it’s not a transmission.

Start by removing the differential cover. Make sure you got some kind of pan underneath the axle; gear oil is going to go everywhere. Once you get this far, spin the carrier around until you see the Cross shaft bolt shown here...

I forget the size of this bolt, but it was quite small; I believe it was actually one of the smallest box wrenches I had! (8mm?) Be careful on this little sucker, too often do we just get in the rhythm of things and forget to take our time and 'feel' what the metal is trying to tell us. Too often does this sucker BREAK! And isn’t easy removing it! What I do to keep myself from getting in this situation, is hit that bolt up with some PBlaster or WD-40. After about 5-10 minutes of letting the penetrate do its job, I bust out the ol' MAPP Gas (20 bucks at most auto parts stores) and I heat the carrier around the bolt. DONT heat the bolt up directly! That should be enough to get that sucker out gracefully. This is what you are trying to accomplish... with the Cross Shaft removed.

With the cross shaft removed the C-Clip port should be in view, Push one of the axles inward (from the side of the axle), which will reveal the c-clip, remove it. Use needle nosed pliers (or just your hands) to pull the C-clips out. Once the c-clips are removed the axle shafts can be pulled. When you go to pull out the axle shafts, be careful not to put too much stress the bearing seal at the end of the axle tube. Do this for both sides.

Remove the four big bolts that hold the carrier bearing caps on (shown below), then try and pull on the carrier/ring gear, to where it will pop out. If it’s too tight to be tugged out, a crow-bar to peal out the carrier. You can pry against ring gear bolts on the backside of the carrier. If you tug right on its sweet spot, you can get the carrier all the way out in just one tug, on one side... if you jar up the carrier (i mean, sort of jamming it side-to-side, which you will probably do your first couple times) you will have to pry from the opposite side (which has no bolts to pry on

Make sure mark the bearing caps between right and left. Those caps are machined to match the housing and do not interchange. If you mix them up you can compare the texture of the machined surface on the cap to the texture in the house. Take notice of the tapered sides of the caps, this will contrast to the tapering on the housing

In the materials list, I mentioned using lithium grease to pre-lube all your bearings with. Lithium grease mixes with gear oil very nicely; making one nice interesting looking pile of grease... it will not hurt your bearings or housing. The lithium grease will stay in the bearings for the first hundred miles and will keep them from breaking down during the all so crucial break-in period. Pack in the lithium grease like you would with heavy grease and a common wheel bearing. Works like a charm.

Now you want to measure the gear run out. This is not highly important and you cannot do it with the ABS ring pressed onto your carrier. The gear back face run out is obtained by pointing the dial indicator at the back of the ring gear (smooth side, not the teeth side). Rotate the driveshaft (pinion flange) and record the amount the needle moves. The maximum run out is 0.003”

Setting up Backlash

Now you want to measure the backlash by putting the dial indicator on the very edge of a tooth on the ring gear, you want the indicator to be perpendicular to the edge of the tooth as you possibly can. If you look closely, some gear manufacturers make a little tapered edge on this section of the teeth, using this area makes pointing the dial indicator very accurate.

The backlash is the amount of slop in between the ring gear and the pinion; you are measuring that distance. (.008"-.015") is the amount you want. You are going to move the carrier left and right by using the shims in your install kit. The stock shims (for me) were .255" on the left and .280 on the right. Use shim flanges in your install kit to put your shims in; the flanges are like .210" each. I started with a .060 shim in each side to start off. If your backlash is tight (or the ring gear is too close to the pinion gear) take the amount of shims on the left and add it to the right; vice versa for the right. You want to keep this balance so your backlash stays consistent. Make sure you torque the bearing caps to 77ftlbs before checking your pattern...

Are your shims pissing you off because they won’t stay in the housing when you try to install the carrier? I have a little trick for you! Coat the shim flanges and shims in gear oil so it can sort of glue them together. This is a great time saver.

Your Pinion Depth

Before you start setting up the pinion depth, I recommend removing the existing inner pinion bearing; using a die grinder, grind down the inside diameter (about .001) on the bearing. This will allow the bearing to slip on and off the pinion with very little effort. This will make the process much easier. Just remember when you are done to get a new bearing pressed on there.

The pinion depth is the next measurement you need to look at. Put some gear marking compound on a couple teeth and turn the pinion to get a little pattern.

You don't need to use a crush sleeve each time you remove the pinion to change shims. It can make things tedious for you and possibly give you a false preload, but most of all leaving the sleeve out teaches you what 16inlbs should feel like. As long the torque it takes to turn the pinion is the same as when you go to set up your final assembly with a crush sleeve, pinion depth will be the same. Just make sure to check it, when you are trying to get a feel for it.

In general, when you are setting up gears you are mainly trying to measure from the face to the flank of the tooth, a perfect heel to toe pattern usually impractical. The reason i say this is because all housings are different. My 8.8 would center heel to toe perfectly, dead center. My dana 35 on the otherhand would jump from extreme toe, to being somewhat off-center towards the heel, when just a simple .002" shim was installed. It was practically impossible for me to get it DEAD center, but its very close. After that i could use .005" shims, and the depth would bearly change. This was due to way the housing was machined, the pinion bore may be slightly offset, crooked, or something, to the axle centerline, (imaginary line that runs down the direct middle of the axle tubes.)

If your pattern seems way too close to the toe, then subtract some shim thickness from your pinion shim. If you are closer to the heel, Add shims. Usually (especially in smaller gear jumps like 3.55 to 4.10) the stock pinion shim should be perfect. My stock pinion shim was a good starting point; with a Jump from 3.27 to 4.56 I was barely too close to the toe for my liking. I dropped the pinion shim by -.002 and it was perfect from there. Remove the carrier and add/subtract the amount in shims on your stock pinion shim to get your pattern

Check your pattern again, and if you like what you got then you basically done! The chart below, taken from the Yukon gear manual, should be able to help you determine the pattern. The pattern is going to be difficult to read on the coast side (a.k.a ghost side) during trial assemblies, or until you adjust the preload on the pinion and carrier bearings. After the preloads' have been set the pattern should be nice and defined. There should be a nice shaped oval centered between face and flank on the drive side, and on the ghost side there should be a nice swoop across the back of the gear, again centered face to flank.

I stole this little snit bit from the Yukon gear install manual. This should help you determine if your gear pattern is correct.

Pinion bearing preload.

You will need a Good breaker bar here. Also an inlb torque wrench that can read as low as 10 inlbs. You probably will want some extra crush sleeves and pinion seals too... Assemble your pinion... shims, inner bearing, crush sleeve, outer bearing, oil slinger, oil seal, pinion flange then finally the OLD pinion nut from your stock gear set. You want to use the old nut to CRUSH the crush sleeve, ill elaborate on this some more in a second...

Start cranking that Nut, it will take a good 200ftlbs to crush that crush sleeve to specification. An impact may only get you so far, but even the ones with like 550ftlb burst fire won’t get that nut as tight as it needs to go. What you are trying to do it shrink that crush sleeve until the bearings are pressed up against the races. Every Quarter turn you put on the pinion nut, tap the pinion with a soft (rubber) hammer. Then use your inlb torque wrench to check the amount of drag that’s on the pinion.

When your preload is close (somewhere like 2-5inlbs), remove the old nut, and start over with the new one. Although it will be MUCH easier the second time around, because the crush sleeve is already crushed. Remember to put some lock-tit on there. The reason its good practice to crush the sleeve with the old nut, is because the threads on the pinion nut taper. The threads on the old nut are worn and will loosen up easily, especially with new bearings. There is some debate on this, and ill go by what I’ve always been taught... and that’s to not re-use the old nut.

It should take 16-29inlbs (on new bearings) to make the pinion move or in other words to correctly preload the pinion bearings. If it goes above that then you have to start over with a new crush sleeve.

It will take about 2 full turns till you close to specification. That’s not exact, you need to check every quarter turn, but once it gets close it happens very quickly. When you feel drag on the pinion, and maybe you are at 4 or 5 inlbs, only a very slight turn is needed; very slight.

Is your preload already too tight before you have even crushed the crush sleeve? Check your pinion seal! Not all pinion seals are created equal; this is why I trust BCA brand pinion seals. Brands like motor city and NAPA tend to sit a little tighter along the dust shield, causing excess drag on the pinion. You don’t need a new pinion seal, just find exactly how much extra drag it produces, keep in mind you have that extra amount of drag. Once you start to crush the crush sleeve, just remember to add that amount of drag, to the drag you are trying to measure for you bearing preload.

Carrier bearing preload

Once your pinion is set, reinstall your carrier. Use the shims you decided had the correct backlash and add .005-.007 to each side to preload the carrier bearings. At this point, if your backlash is close but you would like it tighter/looser, then you can add more to one side to balance it out.

Its going to be a very tight fit, but keep in mind it’s harder to over preload the carrier bearings then to not. Although not impossible, it’s rare because you got to be freggin He-man to press in that tight of a fit. Use a rubber hammer to smack in the carrier. Torque down your bearing caps to 77ftlbs and check your pattern again, just for giggles...

If your pattern is correct, and you feel comfortable with your preloads, then get that sucker back under the truck! You're done! Well...

...almost

The Break-In Period

This is the most crucial part of the gear install.

Gears have to be broken in properly or they will fail within the first 500 miles of installation. Most gear sets fail because people neglect that they need to break in the gears.

It’s pretty easy. Drive for no more then 10-30 minutes at a time. Make sure you give your differential adequate time to cool after driving (at least an hour).

Drive normally. You should be alright gassing the petal a little bit, just put any extreme stress on the differential until the 500 break-in period has expired.

Make sure you set your Trip meter after your install, so you know when the 500 mile mark comes. When it does, change the gear oil. You should take notice of any metal shavings and debris in the gear oil. If anything seems a bit excessive then closely examine the (with gear marking compound) gears and make sure they are meshing properly. You never know, you might have gotten some debris in the shims and gotten a false preload setting?

Links to some other great gear manuals

Yukon Gear installation guide

Corral .net gear install write up - VERY EXPLAINATIONAL!

Randy's Ring and Pinion

AccuAutoParts - Tech help

I like the Accu guys, because they have a Tech email! You can email them with any gear install question, and they respond within 24 hours.

Picture Sources, as well as some more great gearing info writen by a fellow EF member: metroplex.

http://www.redpulsar.us/~coldfusion/TT.html

http://www.redpulsar.us/~coldfusion/tlok.html