-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

- Forums

- Generation Specific Forums

- 1991 - 1994 Explorer Ranger Navajo 1st Generation

- Modified 1991-1994 Explorers

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1 ton SAS into a '91! (build thread?)

- Thread starter rhauf

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

Slowlyvverot

Well-Known Member

- Joined

- August 27, 2009

- Messages

- 790

- Reaction score

- 4

- City, State

- Greensboro, NC

- Year, Model & Trim Level

- 93 ExElTee

sick trail! looks like the 60 is holding up well

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

sick trail! looks like the 60 is holding up well

I managed to break a hub last weekend.. old stock hub though.. which reminds me, i need to order a replacement.

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

I managed to break a hub last weekend.. old stock hub though.. which reminds me, i need to order a replacement.

turns out it was the stub shaft that broke! destroyed the whole spindle.

who know d60s only had 31 spline outers!??

upgraded to 35 spline

Foxracin

Explorer Addict

- Joined

- August 29, 2008

- Messages

- 1,069

- Reaction score

- 2

- City, State

- Mount Holly, NC

- Year, Model & Trim Level

- 1991

Just picked up a 1st gen with a d44/9". We'll see how long that lasts before I'm following in your footsteps!

Where in NC you from?

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

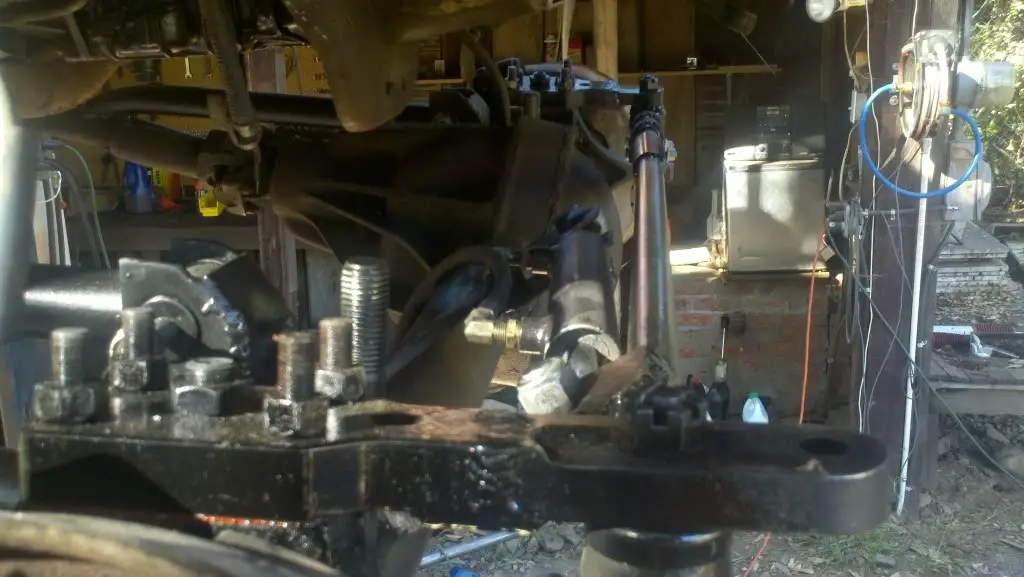

I've decided to go coil sprung front end! (and highsteer and ram assist)

so, i collected the fallowing parts:

ram assist stuff

various steel

various bolts

some bushings

and a variety of various other stuff

today, i started the conversion

we made a tall jack stand to hold the axle in place, then removed the leaf spring

then made this spring perch/link arm mount... which has a 1" bolt for the coil spring retainer. as you can see its pretty much directly on the axles stock leaf spring pad.

and made the link arm.. here it is partially built

and now getting ready to put in.. we also removed the stock spring bucket from the frame rail, it needs to be relocated forward a couple inches. (im placing this axle about 2" forward from where the stock axle would have been)

we cut some holes in the back of the spring bucket to plug weld it so it holds really good

then put it back on in its new location, and did a little painting too

somehow that took all afternoon. so that's day 1 progress.

so, i collected the fallowing parts:

ram assist stuff

various steel

various bolts

some bushings

and a variety of various other stuff

today, i started the conversion

we made a tall jack stand to hold the axle in place, then removed the leaf spring

then made this spring perch/link arm mount... which has a 1" bolt for the coil spring retainer. as you can see its pretty much directly on the axles stock leaf spring pad.

and made the link arm.. here it is partially built

and now getting ready to put in.. we also removed the stock spring bucket from the frame rail, it needs to be relocated forward a couple inches. (im placing this axle about 2" forward from where the stock axle would have been)

we cut some holes in the back of the spring bucket to plug weld it so it holds really good

then put it back on in its new location, and did a little painting too

somehow that took all afternoon. so that's day 1 progress.

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

I made some more progress over the weekend...

Trimmed the cross member for some clearance

The i installed the high steer, set up for chevy 1-ton TRE's. i had to shorten the tie rod a bit.

the problem was, the high steer kit was TOO high. with the springs installed, and sitting on the ground at ride height, the tie rod was only about 2" below the frame, and 1.5" below the pitman arm..

that won't do at all....

...so i did this.

after cutting the high steer knuckles, i ground a real nice groove in them to weld in, so it's still "solid" steel. no air pockets. then i plated the bottom side of each one with 3/16" plate where i welded it.

re-installed it. springs are once again out and it's no longer at "ride height"

Also, got the ram assist squeezed in behind the tie rod

here's a couple more pictures

after that i installed a transmission filter and new seal (it was leaking)

i was also going to replace my transfer case because i thought the rear output bearing was bad.. turned out the flange nut was just loose. tightened it up and its fine now durr!!

and i tore into the leaf spring packs in the rear.. going to shuffle in some of the leaves from the front, get a tiny bit more height and slightly stiffer out of it (plus one of my leaves was cracked and needed to be replaced)

i also "clearanced" the body a tiny bit where the rear driveshaft u joint at the t-case is.. it would rub sometimes, for some reason.

so all i have left is to finish the rear leaves, build the pan-hard bar, and hook up the lines to the ram assist... and a few other details, almost done!

got to get done in time for TDS... first weekend in march. anybody else going?

is anybody fallowing this thread?

Trimmed the cross member for some clearance

The i installed the high steer, set up for chevy 1-ton TRE's. i had to shorten the tie rod a bit.

the problem was, the high steer kit was TOO high. with the springs installed, and sitting on the ground at ride height, the tie rod was only about 2" below the frame, and 1.5" below the pitman arm..

that won't do at all....

...so i did this.

after cutting the high steer knuckles, i ground a real nice groove in them to weld in, so it's still "solid" steel. no air pockets. then i plated the bottom side of each one with 3/16" plate where i welded it.

re-installed it. springs are once again out and it's no longer at "ride height"

Also, got the ram assist squeezed in behind the tie rod

here's a couple more pictures

after that i installed a transmission filter and new seal (it was leaking)

i was also going to replace my transfer case because i thought the rear output bearing was bad.. turned out the flange nut was just loose. tightened it up and its fine now durr!!

and i tore into the leaf spring packs in the rear.. going to shuffle in some of the leaves from the front, get a tiny bit more height and slightly stiffer out of it (plus one of my leaves was cracked and needed to be replaced)

i also "clearanced" the body a tiny bit where the rear driveshaft u joint at the t-case is.. it would rub sometimes, for some reason.

so all i have left is to finish the rear leaves, build the pan-hard bar, and hook up the lines to the ram assist... and a few other details, almost done!

got to get done in time for TDS... first weekend in march. anybody else going?

is anybody fallowing this thread?

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

I got the steering linkage and panhard bar in today!!

The panhard bar is pretty short (only about 18 inches, iirc) so I expect a little bump steer. unfortunately, i couldn't come up with a way to make it longer.

these pictures were taken at "full droop"... the limiting factor being the springs, they only compress about 3" when i set it down... therefore, i only get about 3" of (sprung) downtravel.. with the springs out, it could go down a few more inches before the brake lines are tight.

(at full droop)

(at full droop)

(at full droop)

the good news is, at ride height, the panhard bar and steering linkage are nearly level. so even with my short panhard maybe the bump steer will be tolerable.

up-travel is about 2" to the bump stops, then there is enough clearance to compress the bump stop down to less than 1/2" without anything bottoming out.

heres a side shot with it resting on the bump stop (springs out) you can see my hack job mod on the steering linkage here, too.

the panhard bar mount doubles as a bumpstop risor/pad from the axle as well.

so all in all, i have about 6" of usable travel. I also got these shocks which i'll be using.. i hope they have enough travel :rockon

The panhard bar is pretty short (only about 18 inches, iirc) so I expect a little bump steer. unfortunately, i couldn't come up with a way to make it longer.

these pictures were taken at "full droop"... the limiting factor being the springs, they only compress about 3" when i set it down... therefore, i only get about 3" of (sprung) downtravel.. with the springs out, it could go down a few more inches before the brake lines are tight.

(at full droop)

(at full droop)

(at full droop)

the good news is, at ride height, the panhard bar and steering linkage are nearly level. so even with my short panhard maybe the bump steer will be tolerable.

up-travel is about 2" to the bump stops, then there is enough clearance to compress the bump stop down to less than 1/2" without anything bottoming out.

heres a side shot with it resting on the bump stop (springs out) you can see my hack job mod on the steering linkage here, too.

the panhard bar mount doubles as a bumpstop risor/pad from the axle as well.

so all in all, i have about 6" of usable travel. I also got these shocks which i'll be using.. i hope they have enough travel :rockon

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

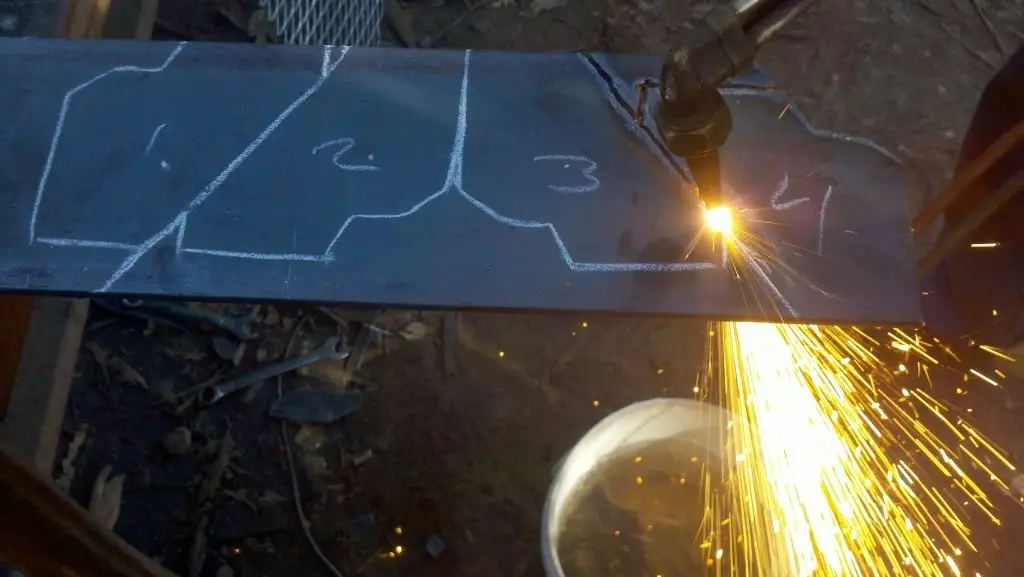

time to put in the front shocks...

cut out some mounts for them

installed one side so far.. i will probably "box" the lower portion of this in. at least on one side.

these shocks are pretty tall!

i'm going to have to relocated the air box and some other stuff for fitment.

I also got the a hitch receiver installed.. well most of the way, i need to brace it a little more on the inside.

the only problem with this hitch is that even with the drop hitch, the ball will be about 29" high. so i'm not sure how usable it will be :/ we will see!

can't have too much welding

cut out some mounts for them

installed one side so far.. i will probably "box" the lower portion of this in. at least on one side.

these shocks are pretty tall!

i'm going to have to relocated the air box and some other stuff for fitment.

I also got the a hitch receiver installed.. well most of the way, i need to brace it a little more on the inside.

the only problem with this hitch is that even with the drop hitch, the ball will be about 29" high. so i'm not sure how usable it will be :/ we will see!

can't have too much welding

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

just for fun.. how about a live webcam?

(image updates when page is refreshed)

with the interest this thread is getting.. i figure it will be really busy (haha)

(image updates when page is refreshed)

with the interest this thread is getting.. i figure it will be really busy (haha)

Mexxx

Member

- Joined

- April 9, 2011

- Messages

- 15

- Reaction score

- 0

- City, State

- Smithers B.C.

- Year, Model & Trim Level

- '94 limited Gold Edition

Hey love your truck. i have a question about your exo cage where it gos thru the roof,

is it hard to keep it sealed there with the frame/cage flex different then the body or dose it not move that much. I see your in a lot warmer/dryer climate then iam so it might not be an issue for you but if i do my cage like the it will have to be sealed

Thank

P.S. your cliff dive video looked like alot of fun

is it hard to keep it sealed there with the frame/cage flex different then the body or dose it not move that much. I see your in a lot warmer/dryer climate then iam so it might not be an issue for you but if i do my cage like the it will have to be sealed

Thank

P.S. your cliff dive video looked like alot of fun

rhauf

Explorer Addict

- Joined

- November 1, 2005

- Messages

- 1,246

- Reaction score

- 7

- City, State

- Ca

- Year, Model & Trim Level

- 91,93,98,&02 Exploders

Hey love your truck. i have a question about your exo cage where it gos thru the roof,

is it hard to keep it sealed there with the frame/cage flex different then the body or dose it not move that much. I see your in a lot warmer/dryer climate then iam so it might not be an issue for you but if i do my cage like the it will have to be sealed

Thank

P.S. your cliff dive video looked like alot of fun

It's just holes cut in the roof with a hole saw.. it drips a little in the rain but that doesnt bother me much.

i have the body mounted solid to the cage and frame in a few spots, for instance where the cage goes up between the doors it is anchored to the body there. otherwise, you would just need a really big hole to allow for cab/frame flex.

i suppose a rubber shift boot or something along those lines could be used to seal the holes if you wanted to.

Mexxx

Member

- Joined

- April 9, 2011

- Messages

- 15

- Reaction score

- 0

- City, State

- Smithers B.C.

- Year, Model & Trim Level

- '94 limited Gold Edition

It's just holes cut in the roof with a hole saw.. it drips a little in the rain but that doesnt bother me much.

i have the body mounted solid to the cage and frame in a few spots, for instance where the cage goes up between the doors it is anchored to the body there. otherwise, you would just need a really big hole to allow for cab/frame flex.

i suppose a rubber shift boot or something along those lines could be used to seal the holes if you wanted to.

thanks ill figure a way to seal it up. we get alot of rain and snow here lol

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

Similar threads

- Replies

- 22

- Views

- 4,289

- Replies

- 10

- Views

- 2,218

- Replies

- 90

- Views

- 19,691