- Joined

- March 3, 2002

- Messages

- 13,738

- Reaction score

- 56

- City, State

- Elkridge, MD

- Year, Model & Trim Level

- 04 4Runner, 22 Silverado

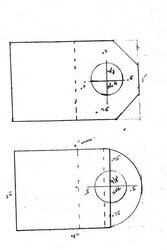

I've been pondering/designing a front winch bumper with a compartments for a optima battery and for accessories like tow straps, winch remotes. Does anyone know the recommended maximum weight the front torsion bar setup can hold or maybe what the weight of a ARB Bull bar is so I can compare.