CheapThrillEX

Well-Known Member

- Joined

- January 7, 2006

- Messages

- 604

- Reaction score

- 3

- City, State

- Middleville, MI (Gun Lake)

- Year, Model & Trim Level

- 93 Explorer Sport

Okay back story first...

Purchased a 1998 Explorer 5.0L for my wife. Engine was bad. No compression on Cyl #1. Story I got was PO was towing a small trailer up a hill when it began to run rough so he hammered the throttle and it popped and then ran horrible. So I purchased truck, pulled engine apart and found the culprit.

Cyl#1 as suspected was damaged. You can see the chunks of piston missing. So I purchased a used good motor from a 2000 Explorer. Treated it as a long block and reused my intakes and all sensors etc.. other then the crank sensor and balancer as those numbers interchange with a 98 5.0L. Installed the motor and about 150 miles later I got a p1309 code. Then soon followed with two O2 sensor codes. I cleared the codes and was fine for another 150 miles. Light returns same codes. Then it started the early morning chirps. So I pulled the cam sensor and syncro out and sure enough spinning the snycro in my hand I can feel the rough spot and chirp. So I purchased a new syncro and sensor from Napa (dorman) which came with the tool. Turned the crank with finger over #1 till air pushed back and then brought it up to align the balancer and pointer at 0. Positioned alignment tool on syncro and dropped into hole with the arrow facing the direct forward on the tool. Put the cam sensor pack on the syncro. Reinstalled everything. Drove the truck for 10 miles to bring it up operating temp and everything, hooked a Modis Scan tool up to it and ran the KOER test and came back clean no codes or faults. Thinking things were on the up and up. Wife came and picked up the truck and calls 20 minutes later and the light is back on and I got the P1309 code again then later came the two o2 codes again.

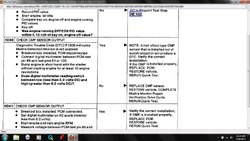

Now I am getting slightly concerned with this Cam sensor issue being the condition of the OE motor I pulled out and the face I cannot seem to shake this code. I do not have the truck with me at work today but plan to run the HD40 test below when I get a chance. but looking for any advice, it doesn't seem as cut and dry to me that the pcm is just bad sense I already have the new syncro and sensor in the truck.

Purchased a 1998 Explorer 5.0L for my wife. Engine was bad. No compression on Cyl #1. Story I got was PO was towing a small trailer up a hill when it began to run rough so he hammered the throttle and it popped and then ran horrible. So I purchased truck, pulled engine apart and found the culprit.

Cyl#1 as suspected was damaged. You can see the chunks of piston missing. So I purchased a used good motor from a 2000 Explorer. Treated it as a long block and reused my intakes and all sensors etc.. other then the crank sensor and balancer as those numbers interchange with a 98 5.0L. Installed the motor and about 150 miles later I got a p1309 code. Then soon followed with two O2 sensor codes. I cleared the codes and was fine for another 150 miles. Light returns same codes. Then it started the early morning chirps. So I pulled the cam sensor and syncro out and sure enough spinning the snycro in my hand I can feel the rough spot and chirp. So I purchased a new syncro and sensor from Napa (dorman) which came with the tool. Turned the crank with finger over #1 till air pushed back and then brought it up to align the balancer and pointer at 0. Positioned alignment tool on syncro and dropped into hole with the arrow facing the direct forward on the tool. Put the cam sensor pack on the syncro. Reinstalled everything. Drove the truck for 10 miles to bring it up operating temp and everything, hooked a Modis Scan tool up to it and ran the KOER test and came back clean no codes or faults. Thinking things were on the up and up. Wife came and picked up the truck and calls 20 minutes later and the light is back on and I got the P1309 code again then later came the two o2 codes again.

Now I am getting slightly concerned with this Cam sensor issue being the condition of the OE motor I pulled out and the face I cannot seem to shake this code. I do not have the truck with me at work today but plan to run the HD40 test below when I get a chance. but looking for any advice, it doesn't seem as cut and dry to me that the pcm is just bad sense I already have the new syncro and sensor in the truck.