ncc

Active Member

- Joined

- November 18, 2005

- Messages

- 77

- Reaction score

- 8

- City, State

- Manchester, NH

- Year, Model & Trim Level

- '97 Eddie Bauer

Hey all! Figuring on all the help I've gotten from this board, I decided the least I could do is try to return the favor. To that end, I've written up exactly what I went through when I replaced all the components on the front end of my Eddie Bauer.

***Please consider changing your spark plugs and wires at the same time you do this project. You'll understand why as we go along.***

This work was performed on a 1997 Eddie Bauer 4.0L SOHC 4x4 four-door with 168,000 miles and what looked like ALL ORIGINAL components.

First a word about techniques, verbiage and tools:

I am what is affectionately known as a "backyard mechanic"; just like the majority of you who use this site. Some of the techniques I use in getting things done are less than desireable to the ASE-certified, professional technicians but they get the job done and with no ill-effects. However, having said that, if I had all the proper equipment like air-tools and a nice lift, then I would do things EXACTLY like the professionals do; their way is, after all, the safest and most correct way of doing things. In other words, keep in mind that this write-up is based on my own level of experience and using my own collection of tools. In the end you must be the one to decide what you are and are not capable of doing.

Verbiage:

1. Shank: I use this term to describe the functional ends of tie-rod ends and other pieces. According to dictionary.com "7. a knob, small projection, or end of a device for attaching to another object, as a small knob on the back of a solid button, or the end of a drill for gripping in a shaft."

2. Zirc fitting: A thread-in fitting (usually gold in appearance) used for delivering grease to a moveable component.

3. Steering knuckle (or knuckle): This is the piece that holds all the chassis components together. The drive axle goes smack through the center of it. They very rarely need replacing.

Tools:

I think I used nearly everything in my tool box for all this work, but the main tools you will definitely need are as follows:

Metric socket set with sizes from 8mm to 21mm.

Metric wrench set with sizes from 8mm to 21mm.

3/8" ratchet with 3" and longer extensions.

Adjustable wrench with max jaw size of 1 1/2"

Flathead screwdriver.

Adjustable pliers.

Needle-nose pliers.

C-clip pliers.

Cat's claw or crowbar.

Tie-rod end puller OR pickle-fork.

Rubber mallet.

5lb Iron mallet.

Jack.

Jack stands.

Some 2x4's to raise your jack if needed.

Lug nut wrench (should have come with your truck).

Safety glasses.

Mechanix gloves if desired.

Plenty of rags.

Okay...let's begin:

First thing, do yourself a favor and take your Ex down to the local self-wash car-wash. Use the high-pressure soap and rinse hoses to vigorously clean the undercarriage and chassis of the vehicle. You WILL thank yourself when you get home to work on it.

1. I'm not going to insult your intelligence by telling you how to jack up your Ex, so go ahead and do it your own way. Place your jack stands under the front crossmember. Put little pieces of 2x4 between the stands and the member to prevent any damage.

2. Remove the wheels. This is what you'll see:

3. Remove the brake caliper (two bolts on the back) and rotor (no bolts or index screws hold this on; it just floats on the hub). Some people have run into stubborn, rusted-on rotors. Usually a few good whacks with Big Bertha will knock them off. If you're not replacing your brakes at this point, then be careful with everything and don't forget to hang your calipers with string or wire so you don't rip the pressure tube.

This is what you will now see:

4. Start with the upper ball joint. There is only one bolt that holds it on. It goes horizontally through the upper shaft of the steering knuckle. This bolt is NOTORIOUSLY hard to remove. The thing to keep in mind is that it is only threaded on the end where the nut goes on. The shank that goes through the steering knuckle/ball joint is smooth. So the easiest thing to do is to put the nut on the very end of the bolt and beat the ever-lovin'-you-know-what out of it until it decides to come out. Here's the bolt as you'll see it before you begin beating it out:

5. If you haven't removed the aforementioned bolt, don't think you can just loosen it and pull the ball joint out. The shank of the ball joint is grooved where the bolt slides through it. Once the bolt is removed, you can pop the ball joint out with a pickle fork. You can use your mallet to coax it along, as well.

6. Now that the ball joint is separated from the steering knuckle, you can go ahead and remove the two bolts that hold the control arm to the frame. You only need one socket to get these out. The nuts are on the outer side of each of the brackets as you're looking at them.

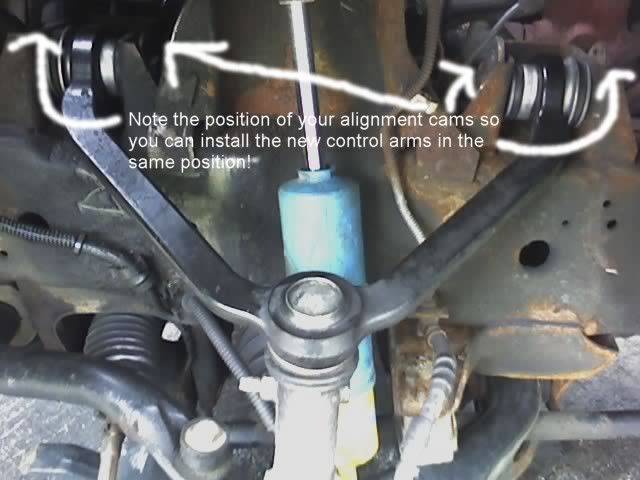

***NOTE*** Make a note of the exact position of the alignment cams in your brackets so you can reinstall them as close as possible. That way your alignment will be close enough to drive on before you have it professionally set.

7. Now let's separate the outer tie-rod end from the knuckle. Pull the cotter pin with a pair of needle-nose pliers and use a 21mm wrench to loosen the bolt. There are a couple of different ways of yanking a tie-rod end: First, you can do the low-tech method of putting the nut on the end of the shank and pounding it up and out with your iron mallet. Or second, you can use a pickle-fork designed for removing tie-rod ends and pry the piece out of its place. You may actually need to do a combination of the two.

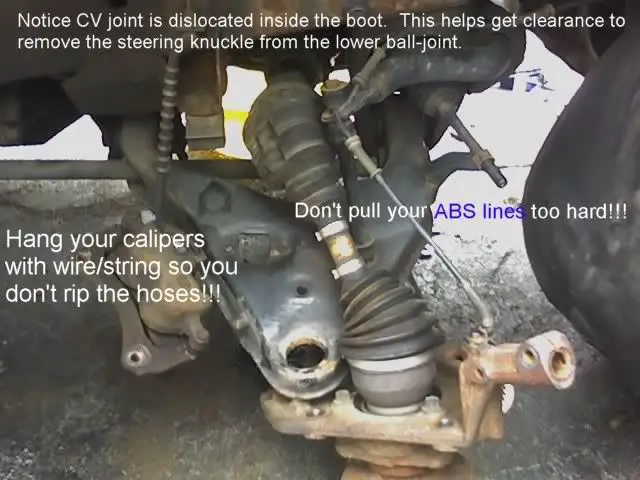

8. With the tie-rod end separated from the knuckle, you now have easy access to the lower ball joint. Remove the cotter pin, take off the nut and pull the knuckle down and away from the piece. It is easier to take the knuckle off the ball joint before trying to take the joint out of the lower control arm. I actually had to pop my inner CV joint (but not actually remove it) to get that extra 3/4" I needed to get the knuckle off the joint. Remove the large C-clip on the top of the joint. Once that's done, just pound the joint down with your mallet to get it out of it's hole.

Now your setup should look like this:

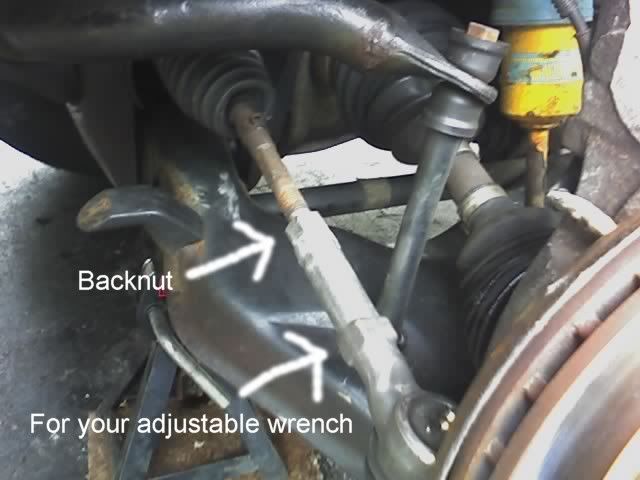

9. Most of the time, it is only the outer tie-rod ends that need replacing. Working on that basis, COUNT THE THREADS that are showing behind the tie-rod end body and write that number down. Then simply put a 21mm wrench on the backnut and your large adjustable on the squared-off body of the rod end and separate the two. This is what you're looking for/at:

10. THIS STEP ONLY IF YOU'RE REPLACING YOUR SHOCKS! Remove two lower 13mm nuts holding the shock studs through the lower control arm. Depending on the type of shock currently installed on your truck you will need to figure out how to remove the top nut from the shock mounting bracket. Some shock makers have an allen head recessed in the top of the tube that you hold the shock tube with while turning the nut. Some makers put a flat spot on the shock tube for a wrench to hold it while you're working the nut; it just all depends on the type of shock you have.

11. With all these components out of the way, now's an excellent time to replace your passenger-side spark plugs and wires. You will never have better access to them.

12. Install new shock.

13. Install new tie-rod end onto inner tie rod. Remember to set it with the same number of threads showing that the old unit had. (I have run into instances with tie-rod ends where the new unit actually had a shorter shaft than the old one even though everything else was the same. Just a manufacturer's discrepancy. So compare the bodies before installation.) Put anti-seize on the inner threads, the shank and the threads at the end of the shank.

14. Install new lower ball joint. Simply push the unit up from the bottom of the lower control arm and install the C-clip on the top. Don't forget to install the zirc fitting if you purchased greaseable units.

15. Install new upper control arm. Don't forget to check your alignment cams! DO NOT ATTACH BALL JOINT TO KNUCKLE YET.

16. Attach the knuckle to the lower ball joint and install the nut. Anti-seize the threads and the shank of the unit. Torque the nut to a good tight fit (some have suggested 60-70ft/lbs) and line up the castellations with the cotter pin hole. DON'T FORGET THE COTTER PIN!!!!

***After attaching lower ball joint to knuckle, you should be able to pop your CV joint back together with no problem.***

17. Attach the tie-rod end to the knuckle. Torque the nut to a good tight fit (some have suggested 45-60ft/lbs) and line up the castellations with the cotter pin hole. DON'T FORGET THE COTTER PIN!!!!

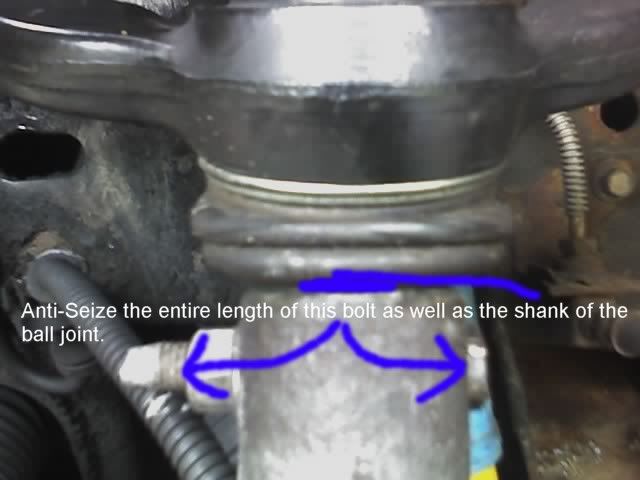

18. Now you can attach the upper ball joint to the knuckle. Anti-seize the threads and the shank of the ball joint. Also anti-seize the bolt that holds it together. You may have to pound that bolt in again. I actually went to the local hardware store and bought new hardened steel bolts for these. I'm not sure what the torque value is for this bolt so I just reefed the heck out of it.

19. Install brake components whether new or old. Rotor first, then calipers. DO NOT FORGET TO TORQUE THE CALIPER BOLTS!!!. This is why: Caliper brake bolt backed out! (Not meant to embarass anyone, but it's a very good discussion about this.)

20. Take a real good look at everything you've done and, if you're satisfied, install the wheels, anti-seize your lugs and install the lug nuts.

21. Lower the vehicle and torque your lug nuts to their specified value. Install trim caps if applicable.

22. Have a professional alignment performed ASAP!!!

CONGRATULATIONS!!! You now have a brand new front-end good for many, many miles of fun and safe driving.

I'm leaving this thread open so that anyone who wants to add anything or even correct me on anything may do so.

Best of luck to everyone!!!

Jeremy

'97 Eddie Bauer 4.0L SOHC

***Please consider changing your spark plugs and wires at the same time you do this project. You'll understand why as we go along.***

This work was performed on a 1997 Eddie Bauer 4.0L SOHC 4x4 four-door with 168,000 miles and what looked like ALL ORIGINAL components.

First a word about techniques, verbiage and tools:

I am what is affectionately known as a "backyard mechanic"; just like the majority of you who use this site. Some of the techniques I use in getting things done are less than desireable to the ASE-certified, professional technicians but they get the job done and with no ill-effects. However, having said that, if I had all the proper equipment like air-tools and a nice lift, then I would do things EXACTLY like the professionals do; their way is, after all, the safest and most correct way of doing things. In other words, keep in mind that this write-up is based on my own level of experience and using my own collection of tools. In the end you must be the one to decide what you are and are not capable of doing.

Verbiage:

1. Shank: I use this term to describe the functional ends of tie-rod ends and other pieces. According to dictionary.com "7. a knob, small projection, or end of a device for attaching to another object, as a small knob on the back of a solid button, or the end of a drill for gripping in a shaft."

2. Zirc fitting: A thread-in fitting (usually gold in appearance) used for delivering grease to a moveable component.

3. Steering knuckle (or knuckle): This is the piece that holds all the chassis components together. The drive axle goes smack through the center of it. They very rarely need replacing.

Tools:

I think I used nearly everything in my tool box for all this work, but the main tools you will definitely need are as follows:

Metric socket set with sizes from 8mm to 21mm.

Metric wrench set with sizes from 8mm to 21mm.

3/8" ratchet with 3" and longer extensions.

Adjustable wrench with max jaw size of 1 1/2"

Flathead screwdriver.

Adjustable pliers.

Needle-nose pliers.

C-clip pliers.

Cat's claw or crowbar.

Tie-rod end puller OR pickle-fork.

Rubber mallet.

5lb Iron mallet.

Jack.

Jack stands.

Some 2x4's to raise your jack if needed.

Lug nut wrench (should have come with your truck).

Safety glasses.

Mechanix gloves if desired.

Plenty of rags.

Okay...let's begin:

First thing, do yourself a favor and take your Ex down to the local self-wash car-wash. Use the high-pressure soap and rinse hoses to vigorously clean the undercarriage and chassis of the vehicle. You WILL thank yourself when you get home to work on it.

1. I'm not going to insult your intelligence by telling you how to jack up your Ex, so go ahead and do it your own way. Place your jack stands under the front crossmember. Put little pieces of 2x4 between the stands and the member to prevent any damage.

2. Remove the wheels. This is what you'll see:

3. Remove the brake caliper (two bolts on the back) and rotor (no bolts or index screws hold this on; it just floats on the hub). Some people have run into stubborn, rusted-on rotors. Usually a few good whacks with Big Bertha will knock them off. If you're not replacing your brakes at this point, then be careful with everything and don't forget to hang your calipers with string or wire so you don't rip the pressure tube.

This is what you will now see:

4. Start with the upper ball joint. There is only one bolt that holds it on. It goes horizontally through the upper shaft of the steering knuckle. This bolt is NOTORIOUSLY hard to remove. The thing to keep in mind is that it is only threaded on the end where the nut goes on. The shank that goes through the steering knuckle/ball joint is smooth. So the easiest thing to do is to put the nut on the very end of the bolt and beat the ever-lovin'-you-know-what out of it until it decides to come out. Here's the bolt as you'll see it before you begin beating it out:

5. If you haven't removed the aforementioned bolt, don't think you can just loosen it and pull the ball joint out. The shank of the ball joint is grooved where the bolt slides through it. Once the bolt is removed, you can pop the ball joint out with a pickle fork. You can use your mallet to coax it along, as well.

6. Now that the ball joint is separated from the steering knuckle, you can go ahead and remove the two bolts that hold the control arm to the frame. You only need one socket to get these out. The nuts are on the outer side of each of the brackets as you're looking at them.

***NOTE*** Make a note of the exact position of the alignment cams in your brackets so you can reinstall them as close as possible. That way your alignment will be close enough to drive on before you have it professionally set.

7. Now let's separate the outer tie-rod end from the knuckle. Pull the cotter pin with a pair of needle-nose pliers and use a 21mm wrench to loosen the bolt. There are a couple of different ways of yanking a tie-rod end: First, you can do the low-tech method of putting the nut on the end of the shank and pounding it up and out with your iron mallet. Or second, you can use a pickle-fork designed for removing tie-rod ends and pry the piece out of its place. You may actually need to do a combination of the two.

8. With the tie-rod end separated from the knuckle, you now have easy access to the lower ball joint. Remove the cotter pin, take off the nut and pull the knuckle down and away from the piece. It is easier to take the knuckle off the ball joint before trying to take the joint out of the lower control arm. I actually had to pop my inner CV joint (but not actually remove it) to get that extra 3/4" I needed to get the knuckle off the joint. Remove the large C-clip on the top of the joint. Once that's done, just pound the joint down with your mallet to get it out of it's hole.

Now your setup should look like this:

9. Most of the time, it is only the outer tie-rod ends that need replacing. Working on that basis, COUNT THE THREADS that are showing behind the tie-rod end body and write that number down. Then simply put a 21mm wrench on the backnut and your large adjustable on the squared-off body of the rod end and separate the two. This is what you're looking for/at:

10. THIS STEP ONLY IF YOU'RE REPLACING YOUR SHOCKS! Remove two lower 13mm nuts holding the shock studs through the lower control arm. Depending on the type of shock currently installed on your truck you will need to figure out how to remove the top nut from the shock mounting bracket. Some shock makers have an allen head recessed in the top of the tube that you hold the shock tube with while turning the nut. Some makers put a flat spot on the shock tube for a wrench to hold it while you're working the nut; it just all depends on the type of shock you have.

11. With all these components out of the way, now's an excellent time to replace your passenger-side spark plugs and wires. You will never have better access to them.

12. Install new shock.

13. Install new tie-rod end onto inner tie rod. Remember to set it with the same number of threads showing that the old unit had. (I have run into instances with tie-rod ends where the new unit actually had a shorter shaft than the old one even though everything else was the same. Just a manufacturer's discrepancy. So compare the bodies before installation.) Put anti-seize on the inner threads, the shank and the threads at the end of the shank.

14. Install new lower ball joint. Simply push the unit up from the bottom of the lower control arm and install the C-clip on the top. Don't forget to install the zirc fitting if you purchased greaseable units.

15. Install new upper control arm. Don't forget to check your alignment cams! DO NOT ATTACH BALL JOINT TO KNUCKLE YET.

16. Attach the knuckle to the lower ball joint and install the nut. Anti-seize the threads and the shank of the unit. Torque the nut to a good tight fit (some have suggested 60-70ft/lbs) and line up the castellations with the cotter pin hole. DON'T FORGET THE COTTER PIN!!!!

***After attaching lower ball joint to knuckle, you should be able to pop your CV joint back together with no problem.***

17. Attach the tie-rod end to the knuckle. Torque the nut to a good tight fit (some have suggested 45-60ft/lbs) and line up the castellations with the cotter pin hole. DON'T FORGET THE COTTER PIN!!!!

18. Now you can attach the upper ball joint to the knuckle. Anti-seize the threads and the shank of the ball joint. Also anti-seize the bolt that holds it together. You may have to pound that bolt in again. I actually went to the local hardware store and bought new hardened steel bolts for these. I'm not sure what the torque value is for this bolt so I just reefed the heck out of it.

19. Install brake components whether new or old. Rotor first, then calipers. DO NOT FORGET TO TORQUE THE CALIPER BOLTS!!!. This is why: Caliper brake bolt backed out! (Not meant to embarass anyone, but it's a very good discussion about this.)

20. Take a real good look at everything you've done and, if you're satisfied, install the wheels, anti-seize your lugs and install the lug nuts.

21. Lower the vehicle and torque your lug nuts to their specified value. Install trim caps if applicable.

22. Have a professional alignment performed ASAP!!!

CONGRATULATIONS!!! You now have a brand new front-end good for many, many miles of fun and safe driving.

I'm leaving this thread open so that anyone who wants to add anything or even correct me on anything may do so.

Best of luck to everyone!!!

Jeremy

'97 Eddie Bauer 4.0L SOHC

That's worth another 3 months

That's worth another 3 months