2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,597

- Reaction score

- 334

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Background

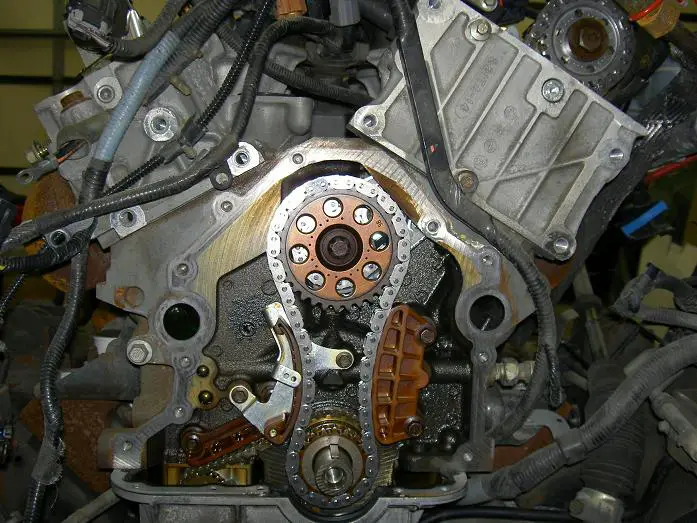

The single overhead camshaft (SOHC) V6 engine may have as many as four timing chains with associated tensioners and guides. The main timing chain connects a sprocket on the crankshaft with a sprocket on the jackshaft as shown in the photo below by CDW6212R.

The jackshaft is in the same location as the camshaft on the overhead valve (OHV) V6 engine. The primary sprocket on the jackshaft is larger in diameter than the sprocket on the crankshaft. The secondary sprocket on the jackshaft is smaller than the sprocket on the camshaft. The combined ratios result in the crankshaft making two revolutions for one revolution of the camshaft. As the crankshaft sprocket rotates the teeth engaging the chain pull the jackshaft sprocket on one side. I call that side the traction side. The chain on the opposite side would be relaxed if it weren't for an installed tensioner. I call that side the slack side. The tensioner is only spring loaded unlike the OHV V6 tensioner that is spring and oil pressure loaded.

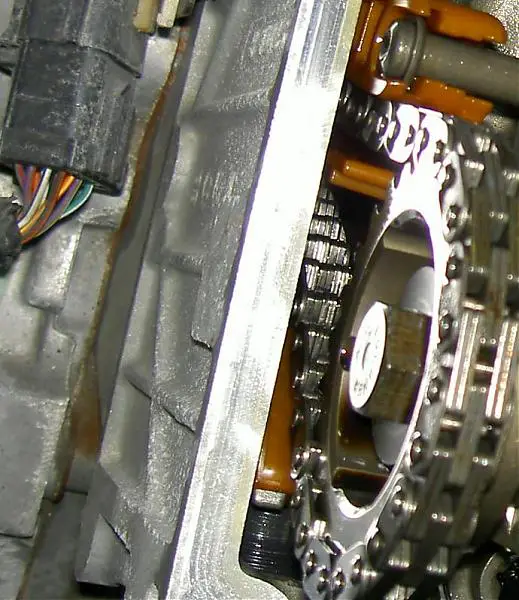

Behind the primary (large) jackshaft sprocket is the secondary (smaller) sprocket not visible in the above photo. This sprocket engages a chain that pulls a sprocket mounted on the camshaft located in the left (driver side) head. There is a guide assembly that limits the amount of side-to-side chain deflection and there is a spring/hydraulic tensioner on the slack side as shown in the photo below by CDW6212R.

The left upper chain guide assembly is shown in the photo below by ipwizard.

The guide assembly, chain and sprockets comprise the timing chain cassette.

The configuration of the camshaft chain drive for the right (passenger side) head is rather unique. A sprocket is mounted on the rear of the jackshaft and a sprocket is mounted on the rear of the right camshaft. The two sprockets are connected via a chain with associated guide assembly and tensioner on the slack side as shown in the photo below by CDW6212R.

The tensioner is at the very bottom center of the photo.

The engines in four wheel drive models and some of the later two wheel drive models have a balance shaft in the right side of the upper oil pan. On these engines there is another crankshaft sprocket located behind the front sprocket and a sprocket on the front of the balance shaft. The two sprockets are connected via a chain with associated guide on the traction side and tensioner on the slack side. Some of the components are visible in the first photo of this post.

The single overhead camshaft (SOHC) V6 engine may have as many as four timing chains with associated tensioners and guides. The main timing chain connects a sprocket on the crankshaft with a sprocket on the jackshaft as shown in the photo below by CDW6212R.

The jackshaft is in the same location as the camshaft on the overhead valve (OHV) V6 engine. The primary sprocket on the jackshaft is larger in diameter than the sprocket on the crankshaft. The secondary sprocket on the jackshaft is smaller than the sprocket on the camshaft. The combined ratios result in the crankshaft making two revolutions for one revolution of the camshaft. As the crankshaft sprocket rotates the teeth engaging the chain pull the jackshaft sprocket on one side. I call that side the traction side. The chain on the opposite side would be relaxed if it weren't for an installed tensioner. I call that side the slack side. The tensioner is only spring loaded unlike the OHV V6 tensioner that is spring and oil pressure loaded.

Behind the primary (large) jackshaft sprocket is the secondary (smaller) sprocket not visible in the above photo. This sprocket engages a chain that pulls a sprocket mounted on the camshaft located in the left (driver side) head. There is a guide assembly that limits the amount of side-to-side chain deflection and there is a spring/hydraulic tensioner on the slack side as shown in the photo below by CDW6212R.

The left upper chain guide assembly is shown in the photo below by ipwizard.

The guide assembly, chain and sprockets comprise the timing chain cassette.

The configuration of the camshaft chain drive for the right (passenger side) head is rather unique. A sprocket is mounted on the rear of the jackshaft and a sprocket is mounted on the rear of the right camshaft. The two sprockets are connected via a chain with associated guide assembly and tensioner on the slack side as shown in the photo below by CDW6212R.

The tensioner is at the very bottom center of the photo.

The engines in four wheel drive models and some of the later two wheel drive models have a balance shaft in the right side of the upper oil pan. On these engines there is another crankshaft sprocket located behind the front sprocket and a sprocket on the front of the balance shaft. The two sprockets are connected via a chain with associated guide on the traction side and tensioner on the slack side. Some of the components are visible in the first photo of this post.