239

Well-Known Member

- Joined

- April 4, 2011

- Messages

- 762

- Reaction score

- 131

- City, State

- Bonita Springs, FL

- Year, Model & Trim Level

- 2000 XLT, V6 OHV

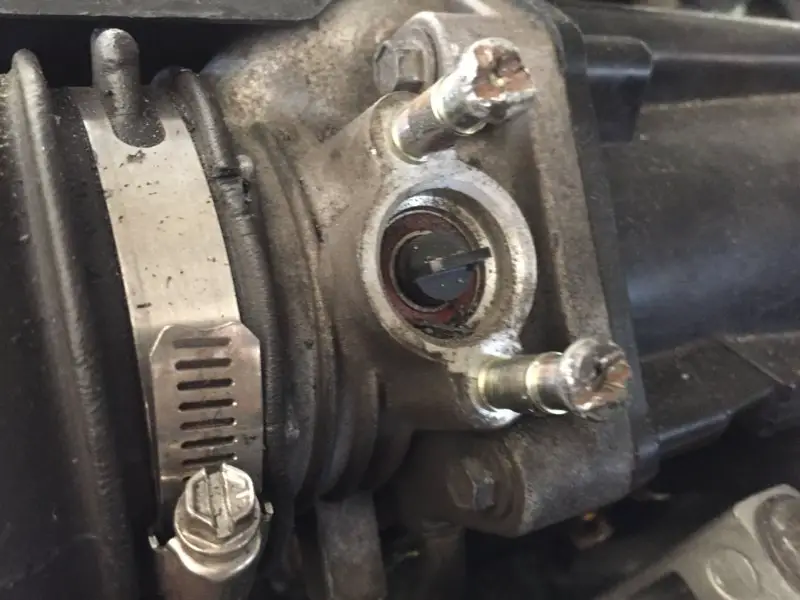

A couple of years ago I got the idea of replacing my throttle position sensor since it was the stock part. I gave up after rounding the philips screws. I then tired to use a dremel to cut a slot into the screw heads but that didn’t work out too well.

Recently, my absolute throttle position would be different every time I drove the truck. Sometimes it would be at 18.8% and other times as high as 21%. I finally purchased a dremel torch to heat the screws and proceeded to destroy the old tps.

From here I applied heat and then began to turn the screw with some vampliers.

The round part of the pliers grabs on great and fits snug on the screw heads. Finally, I had removed the old, faulty sensor and had a Motorcraft replacement on. My absolute throttle position is always at 18.4% now, at idle. I used bolts to replace the philips screws this time. The size of the bolts are

5x30x.80 and are the same on the SOHC, from what I saw on YouTube.

My throttle response is better now and acceleration is too, which really surprised me when I first drove with a new tps. I read about testing the tps with a multimeter but I could tell mine was bad just by watching it on my blue driver obd scanner.

The parts I used were:

Throttle Position Sensor 2000 OHV: CX1542

Pliers: VT001

Bolts: Stainless 5x30x.80

Recently, my absolute throttle position would be different every time I drove the truck. Sometimes it would be at 18.8% and other times as high as 21%. I finally purchased a dremel torch to heat the screws and proceeded to destroy the old tps.

From here I applied heat and then began to turn the screw with some vampliers.

The round part of the pliers grabs on great and fits snug on the screw heads. Finally, I had removed the old, faulty sensor and had a Motorcraft replacement on. My absolute throttle position is always at 18.4% now, at idle. I used bolts to replace the philips screws this time. The size of the bolts are

5x30x.80 and are the same on the SOHC, from what I saw on YouTube.

My throttle response is better now and acceleration is too, which really surprised me when I first drove with a new tps. I read about testing the tps with a multimeter but I could tell mine was bad just by watching it on my blue driver obd scanner.

The parts I used were:

Throttle Position Sensor 2000 OHV: CX1542

Pliers: VT001

Bolts: Stainless 5x30x.80