2000StreetRod

Moderator Emeritus

- Joined

- May 26, 2009

- Messages

- 10,562

- Reaction score

- 349

- City, State

- Greenville, SC

- Year, Model & Trim Level

- 00 Sport FI, 03 Ltd V8

Background

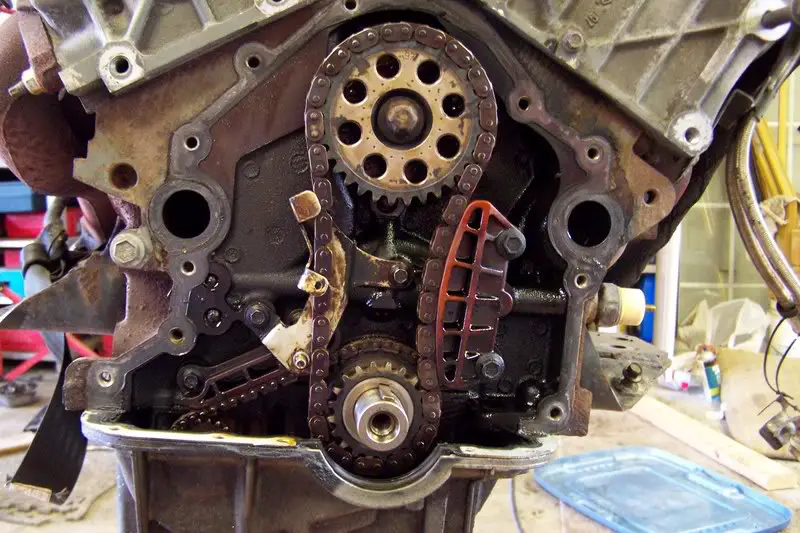

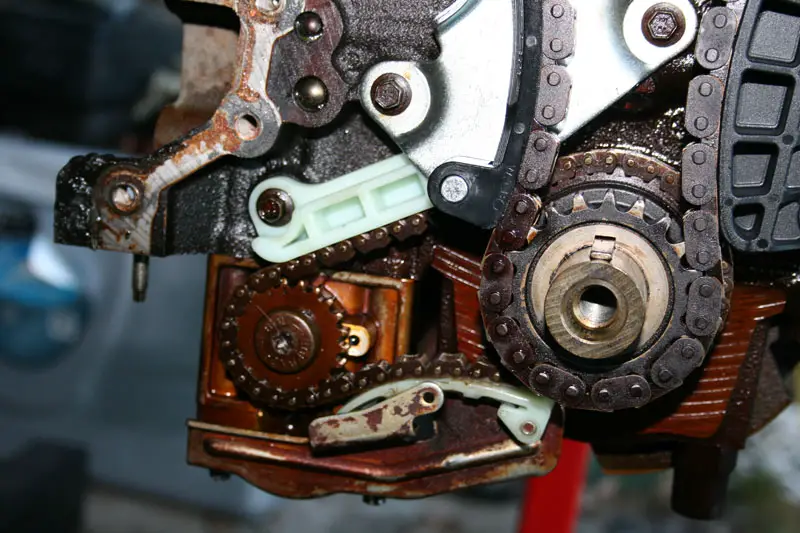

There are multiple possible sources of rattle for vehicles with the 4.0L SOHC V6. See Timing chain rattle resolution process - SOHC V6 . Sometimes the location of the rattle source can be detected by using a mechanic's stethoscope or a length of flexible hose. However, internal engine sounds echo off the block walls making locating the source difficult. A frequent symptom of a failed primary (crankshaft to jackshaft) chain tensioner is rattle at mid-range (2,500 to 3,000 rpm) engine speed. Unfortunately, a failed balance shaft chain tensioner exhibits similar rattle characteristics. Normally, it is an exception for an engine with the balance shaft to be installed in a rear wheel drive vehicle. Inspection of the balance shaft and primary chain tensioners require removal of the front timing cover.

Because of high failures of the original primary chain tensioner incorporated in the 1997 thru 2001 models Ford upgraded the tensioner by increasing the base area and the number of spring leaves from three to six.

The upgraded tensioner was incorporated in 2002 and later models. Since joining the forum in May, 2009 after purchasing my 2000 Sport, I don't recall any member posting that the engine was damaged due to a failed primary chain tensioner. The primary chain is very strong and will destroy the tensioner long before the chain is significantly damaged. When my engine was dismantled to replace the timing chain components, even with no tensioner installed there was insufficient slack to slip the primary chain on either the crankshaft or jackshaft sprockets. The main concern for a failed primary chain tensioner is that broken pieces could block an oil passage resulting in bearing failure.

Replacement of the balance shaft chain tensioner additionally requires removal of the block cradle (upper oil pan).

Usually, when either tensioner fails, parts can be detected by removing the lower oil pan and inspecting. Since removing the front cover requires significant time and the replacement of the gasket, balancer retaining bolt and possibly the crankshaft oil seal, I suggest pulling the oil pan and inspecting for parts as the next diagnostic step after listening with a stethoscope or hose.

Procedure to replace the primary chain tensioner on a 2000 Explorer 4.0L SOHC V6.

Primary Chain Tensioner Removal

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

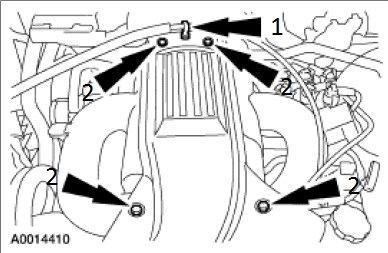

3. Remove the engine appearance cover.

3.1. Disconnect the speed control cable (if equipped).

3.2. Remove the bolts.

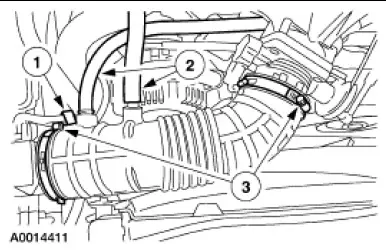

4. Remove the air cleaner outlet tube.

4.1. Unclip the wire harness.

4.2. Disconnect the crankcase ventilation tubes.

4.3. Loosen the air cleaner outlet tube clamps and remove the air cleaner outlet tube.

There are multiple possible sources of rattle for vehicles with the 4.0L SOHC V6. See Timing chain rattle resolution process - SOHC V6 . Sometimes the location of the rattle source can be detected by using a mechanic's stethoscope or a length of flexible hose. However, internal engine sounds echo off the block walls making locating the source difficult. A frequent symptom of a failed primary (crankshaft to jackshaft) chain tensioner is rattle at mid-range (2,500 to 3,000 rpm) engine speed. Unfortunately, a failed balance shaft chain tensioner exhibits similar rattle characteristics. Normally, it is an exception for an engine with the balance shaft to be installed in a rear wheel drive vehicle. Inspection of the balance shaft and primary chain tensioners require removal of the front timing cover.

Because of high failures of the original primary chain tensioner incorporated in the 1997 thru 2001 models Ford upgraded the tensioner by increasing the base area and the number of spring leaves from three to six.

The upgraded tensioner was incorporated in 2002 and later models. Since joining the forum in May, 2009 after purchasing my 2000 Sport, I don't recall any member posting that the engine was damaged due to a failed primary chain tensioner. The primary chain is very strong and will destroy the tensioner long before the chain is significantly damaged. When my engine was dismantled to replace the timing chain components, even with no tensioner installed there was insufficient slack to slip the primary chain on either the crankshaft or jackshaft sprockets. The main concern for a failed primary chain tensioner is that broken pieces could block an oil passage resulting in bearing failure.

Replacement of the balance shaft chain tensioner additionally requires removal of the block cradle (upper oil pan).

Usually, when either tensioner fails, parts can be detected by removing the lower oil pan and inspecting. Since removing the front cover requires significant time and the replacement of the gasket, balancer retaining bolt and possibly the crankshaft oil seal, I suggest pulling the oil pan and inspecting for parts as the next diagnostic step after listening with a stethoscope or hose.

Procedure to replace the primary chain tensioner on a 2000 Explorer 4.0L SOHC V6.

Primary Chain Tensioner Removal

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove the engine appearance cover.

3.1. Disconnect the speed control cable (if equipped).

3.2. Remove the bolts.

4. Remove the air cleaner outlet tube.

4.1. Unclip the wire harness.

4.2. Disconnect the crankcase ventilation tubes.

4.3. Loosen the air cleaner outlet tube clamps and remove the air cleaner outlet tube.