-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

410Custom's builds a 2007 Ranger V8 - custom truck build - Project "Ranger Premier"

- Thread starter 410Fortune

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- January 22, 2007

- Messages

- 10,173

- Reaction score

- 2,206

- City, State

- selkirk, manitoba

- Year, Model & Trim Level

- 98 supercharged 347 sport

fordpickupman

Well-Known Member

- Joined

- March 18, 2011

- Messages

- 311

- Reaction score

- 263

- City, State

- Cascade, ID

- Year, Model & Trim Level

- 94 XLT

71 F250 Fummins

Great work Jamie

- Joined

- February 8, 1999

- Messages

- 35,502

- Reaction score

- 4,570

- City, State

- Wayoutin, Aridzona

- Year, Model & Trim Level

- '93 XL '20 ST

- Callsign

- AB7FH

I will let the video speak for itself

Build Thread updates are coming

Sounds like it's running great. Congrats

- Joined

- November 11, 2014

- Messages

- 427

- Reaction score

- 411

- Location

- Not far enough from Seattle!

- City, State

- Kent WA

- Year, Model & Trim Level

- 2005 Sport Trac Adrenalin

I watched that cranked up in the garage. The dogs came running out thinking it was time to go for a ride in the '66.

- Joined

- December 22, 2021

- Messages

- 6,997

- Reaction score

- 5,418

- City, State

- Los Angeles, CA

- Year, Model & Trim Level

- 1998 XLT 4x4

24 Rngr 4x4

probably sounds close enough! if tht was in my garage id come running out too!I watched that cranked up in the garage. The dogs came running out thinking it was time to go for a ride in the '66.

- Joined

- November 11, 2014

- Messages

- 427

- Reaction score

- 411

- Location

- Not far enough from Seattle!

- City, State

- Kent WA

- Year, Model & Trim Level

- 2005 Sport Trac Adrenalin

fordpickupman

Well-Known Member

- Joined

- March 18, 2011

- Messages

- 311

- Reaction score

- 263

- City, State

- Cascade, ID

- Year, Model & Trim Level

- 94 XLT

71 F250 Fummins

That's going to be a fun ranger. Wish I lived closer so I could go for a ride. I love that blue color too.

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

All right so the last time we saw the truck it was running, shifting and had brakes!

Instrument cluster mostly working as well.

Nobody in the videos pointed out that the cruise control had been re located, and the arb pump was in place,

lights in the bumper, .... and the truck obviously has driveshafts and more

you guys maybe slippin!

HAHAHAHA

Anyways it has been a long hard few weeks, most of the time was spent on the seats and console install........

Lets check it out

I will start with the instrument cluster:

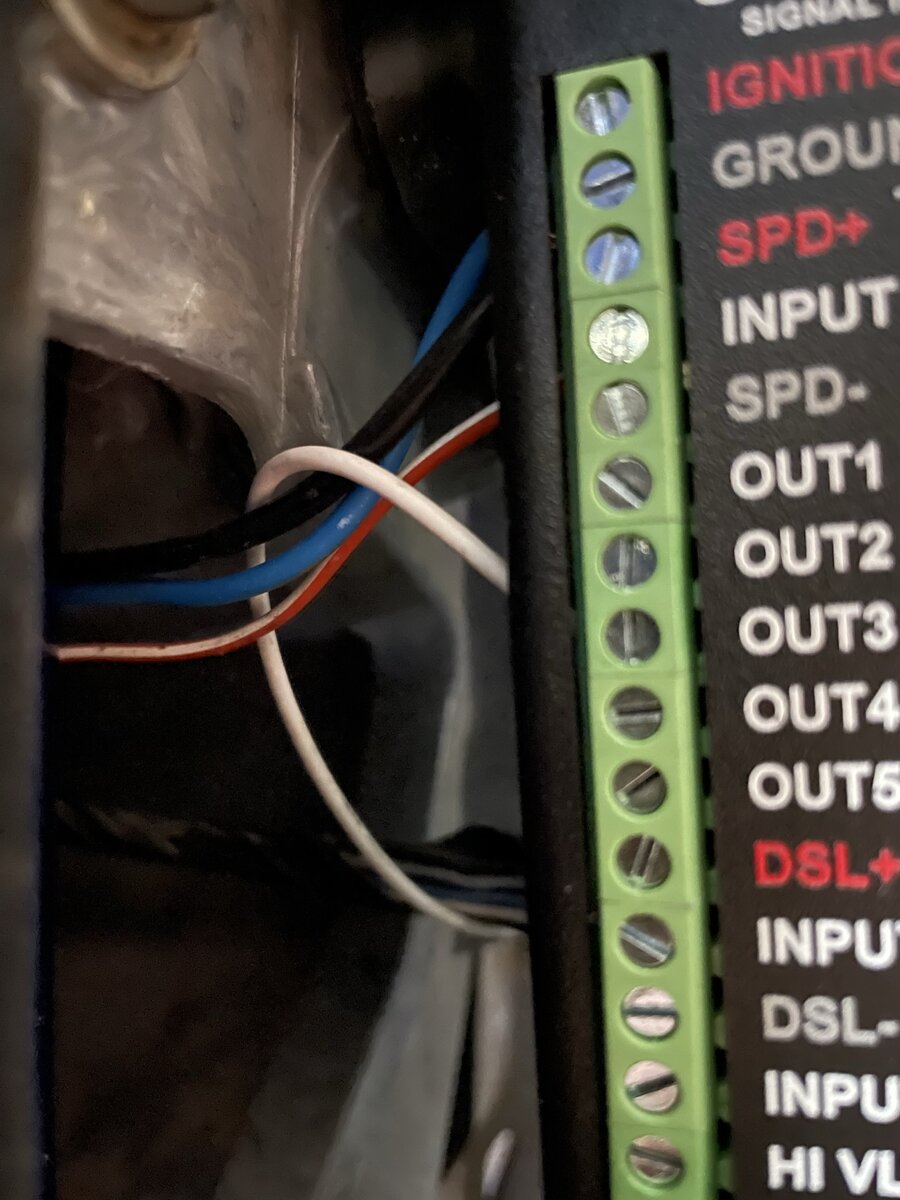

In order to get a working speedometer I needed to install the Dakota Digital speedometer interface.

Really easy to wire up after you have done a few of these.

Basically Dakota Digital (DD) gets its input speed signal from the VSS in the rear axle. The VSS sensor in the rear end is a reliable place to take a reading.

The VSS wires from the rear axle speed sensor head directly to the 4WABS control module under the hood. This is true for most 98-11 Rangers, Explorers, etc

The ABS module then processes this signal and sends it on to many systems in the truck.

However the speedometer and cruise control use a different signal

The old 2007 PCM from the SOHC engine would have done the speed signal "buffering" for the speedometer and cruise.

Traditionally ford speedometers need to see 8000 pulses per mile, this 05 cluster is no different.

Wiring the Dakota SGI 100BT

I get my rear axle VSS signal + wire at the ABS pump. I only need to run this one wire into the dash

07 ranger the wire is white/black

I soldered a brown wire to the rear axle VSS + and used a pass through from a 05 Ranger to get some wires through the dash cleanly

I needed to run tachometer signal from Holley to the cluster, reverse light feed into the interior and a few others

The Dakota box gets 4 wires total on this truck

1. ACC power on (BLUE hot in start and run) taken from ignition switch

2. Ground BLACK chassis ground right near e brake pedal

3. VSS + in (BROWN from our ABS motor turns to red/white inside near cluster)

4. Buffered VSS signal out (WHITE direct to 05 cluster, speedometer in and cruise control) This wire is hooked to OUTPUT 3 for our use, explained below

Much time spent finding the perfect mounting location and fabricating mounts for these electronics

This is the perfect place to put this in a late model Ranger, the old fuse box cover, Thanks Ford for keeping this cover even after the fuse box went MIA in 2002. The dakota is adjusted while driving using two buttons on the faceplate, or while idling, and it can also be adjusted via bluetooth with the Dakota app (can be installed on Android stereo/ head unit)

I have already set a few of these up in our trucks. I copied and pasted the setup instructions from another thread:

Now you need to setup your Dakota box so it will work for us with application 3

referring to the instructions found here: https://www.dakotadigital.com/pdf/sgi-100BT.pdf

Set the Dakota box to convert a high signal to a low signal (H-L) or application 3

Any signal over 32000 ppm is considered a HIGH signal (for us its 77,760ppm)

Any signal under 32000 is considered a LOW signal (for us the target is 8000ppm)

Application 3 settings seen here:

Set the CAL value to 1.65

Using output 3 will send 1/16 of that value to the black/grey 679 vss+ signal to modules.

The math goes like this:

Figuring out the VSS PPM:

Tire revolutions per mile x ring gear teeth = VSS generated signal to ABS pump

29" tire revolves 720 times in a mile

Our 8.8 ring gear has 108 teeth, so

720 x 108 = 77,760 pulses per mile (ppm)

being sent to the ABS motor from the rear axle VSS

77,760 needs to be factored up so that 1/16 of it is close to the target 8000ppm.

(1/16 of something is the same as saying multiply by 0.0625)

So

(77,760 x __________ ) x 0.0625 = 8000

77760 x 1.65 = 128,304

128,304 x 0.0625 = 8019 pretty dang close

Can also say it like this:

1/16 of 128,304 = 8019 PPM

That is how we get our CAL value of 1.65 and know we need to use output3 which is 1/16 of that value

This will give us a working speedometer that can be adjusted for larger tires, gearing changes, changes in pressure as you go!!

Instrument cluster mostly working as well.

Nobody in the videos pointed out that the cruise control had been re located, and the arb pump was in place,

lights in the bumper, .... and the truck obviously has driveshafts and more

you guys maybe slippin!

HAHAHAHA

Anyways it has been a long hard few weeks, most of the time was spent on the seats and console install........

Lets check it out

I will start with the instrument cluster:

In order to get a working speedometer I needed to install the Dakota Digital speedometer interface.

Really easy to wire up after you have done a few of these.

Basically Dakota Digital (DD) gets its input speed signal from the VSS in the rear axle. The VSS sensor in the rear end is a reliable place to take a reading.

The VSS wires from the rear axle speed sensor head directly to the 4WABS control module under the hood. This is true for most 98-11 Rangers, Explorers, etc

The ABS module then processes this signal and sends it on to many systems in the truck.

However the speedometer and cruise control use a different signal

The old 2007 PCM from the SOHC engine would have done the speed signal "buffering" for the speedometer and cruise.

Traditionally ford speedometers need to see 8000 pulses per mile, this 05 cluster is no different.

Wiring the Dakota SGI 100BT

I get my rear axle VSS signal + wire at the ABS pump. I only need to run this one wire into the dash

07 ranger the wire is white/black

I soldered a brown wire to the rear axle VSS + and used a pass through from a 05 Ranger to get some wires through the dash cleanly

I needed to run tachometer signal from Holley to the cluster, reverse light feed into the interior and a few others

The Dakota box gets 4 wires total on this truck

1. ACC power on (BLUE hot in start and run) taken from ignition switch

2. Ground BLACK chassis ground right near e brake pedal

3. VSS + in (BROWN from our ABS motor turns to red/white inside near cluster)

4. Buffered VSS signal out (WHITE direct to 05 cluster, speedometer in and cruise control) This wire is hooked to OUTPUT 3 for our use, explained below

Much time spent finding the perfect mounting location and fabricating mounts for these electronics

This is the perfect place to put this in a late model Ranger, the old fuse box cover, Thanks Ford for keeping this cover even after the fuse box went MIA in 2002. The dakota is adjusted while driving using two buttons on the faceplate, or while idling, and it can also be adjusted via bluetooth with the Dakota app (can be installed on Android stereo/ head unit)

I have already set a few of these up in our trucks. I copied and pasted the setup instructions from another thread:

Now you need to setup your Dakota box so it will work for us with application 3

referring to the instructions found here: https://www.dakotadigital.com/pdf/sgi-100BT.pdf

Set the Dakota box to convert a high signal to a low signal (H-L) or application 3

Any signal over 32000 ppm is considered a HIGH signal (for us its 77,760ppm)

Any signal under 32000 is considered a LOW signal (for us the target is 8000ppm)

Application 3 settings seen here:

Set the CAL value to 1.65

Using output 3 will send 1/16 of that value to the black/grey 679 vss+ signal to modules.

The math goes like this:

Figuring out the VSS PPM:

Tire revolutions per mile x ring gear teeth = VSS generated signal to ABS pump

29" tire revolves 720 times in a mile

Our 8.8 ring gear has 108 teeth, so

720 x 108 = 77,760 pulses per mile (ppm)

being sent to the ABS motor from the rear axle VSS

77,760 needs to be factored up so that 1/16 of it is close to the target 8000ppm.

(1/16 of something is the same as saying multiply by 0.0625)

So

(77,760 x __________ ) x 0.0625 = 8000

77760 x 1.65 = 128,304

128,304 x 0.0625 = 8019 pretty dang close

Can also say it like this:

1/16 of 128,304 = 8019 PPM

That is how we get our CAL value of 1.65 and know we need to use output3 which is 1/16 of that value

This will give us a working speedometer that can be adjusted for larger tires, gearing changes, changes in pressure as you go!!

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

Now I spent ALOT of time looking for the perfect location for the ARB locker air compressor

I have had one of these (older version) under the hood of my BII since 1999 or so?? It still works like new to this day/. My wifes FJ cruiser also mounted compressor under the hood. Under the hood works it keeps them out of the elements cuts down on the noise and makes for a cleaner install w all the wiring and plumbing following factory routes. Also closer to the power distribution and dash for the switches.

I wanted to put it under the hood for sure. Other options were under the truck, behind the grill, and a few others I looked at.

I finally decided to keep it simple

found a perfect location for the cruise control and used the factory cruise control bracket (or two) to mount things

ARB system wiring harness mounted in truck and ran

ARB HO Air compressor, factory mounting brackets are very nice, lots of ways to rotate and move things around to suit your needs

This is where I want the compressor to land

factory cruise control hanger melded w arb compressor mount

mounts with one bolt

The main fuse for the arb system easily accessed

Compressor mounted

Now the cruise control will need a bracket

I used a second factory cruise mount to make this so

Drilled one hole in truck

Clears the hood hinge cable and all wiring reaches no problem, perfect!!

I have had one of these (older version) under the hood of my BII since 1999 or so?? It still works like new to this day/. My wifes FJ cruiser also mounted compressor under the hood. Under the hood works it keeps them out of the elements cuts down on the noise and makes for a cleaner install w all the wiring and plumbing following factory routes. Also closer to the power distribution and dash for the switches.

I wanted to put it under the hood for sure. Other options were under the truck, behind the grill, and a few others I looked at.

I finally decided to keep it simple

found a perfect location for the cruise control and used the factory cruise control bracket (or two) to mount things

ARB system wiring harness mounted in truck and ran

ARB HO Air compressor, factory mounting brackets are very nice, lots of ways to rotate and move things around to suit your needs

This is where I want the compressor to land

factory cruise control hanger melded w arb compressor mount

mounts with one bolt

The main fuse for the arb system easily accessed

Compressor mounted

Now the cruise control will need a bracket

I used a second factory cruise mount to make this so

Drilled one hole in truck

Clears the hood hinge cable and all wiring reaches no problem, perfect!!

- Joined

- January 22, 2007

- Messages

- 10,173

- Reaction score

- 2,206

- City, State

- selkirk, manitoba

- Year, Model & Trim Level

- 98 supercharged 347 sport

*cough tachometer cough*

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

The tachometer works? Hooks up directly to wire from Holley

I show it working in the videos silly

I show it working in the videos silly

- Joined

- January 22, 2007

- Messages

- 10,173

- Reaction score

- 2,206

- City, State

- selkirk, manitoba

- Year, Model & Trim Level

- 98 supercharged 347 sport

i knew it worked, i did see it in the video lol. what i didnt know was how you got it to work.The tachometer works? Hooks up directly to wire from Holley

I show it working in the videos silly

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

Sure man I will show you how I wired the tachometer!!

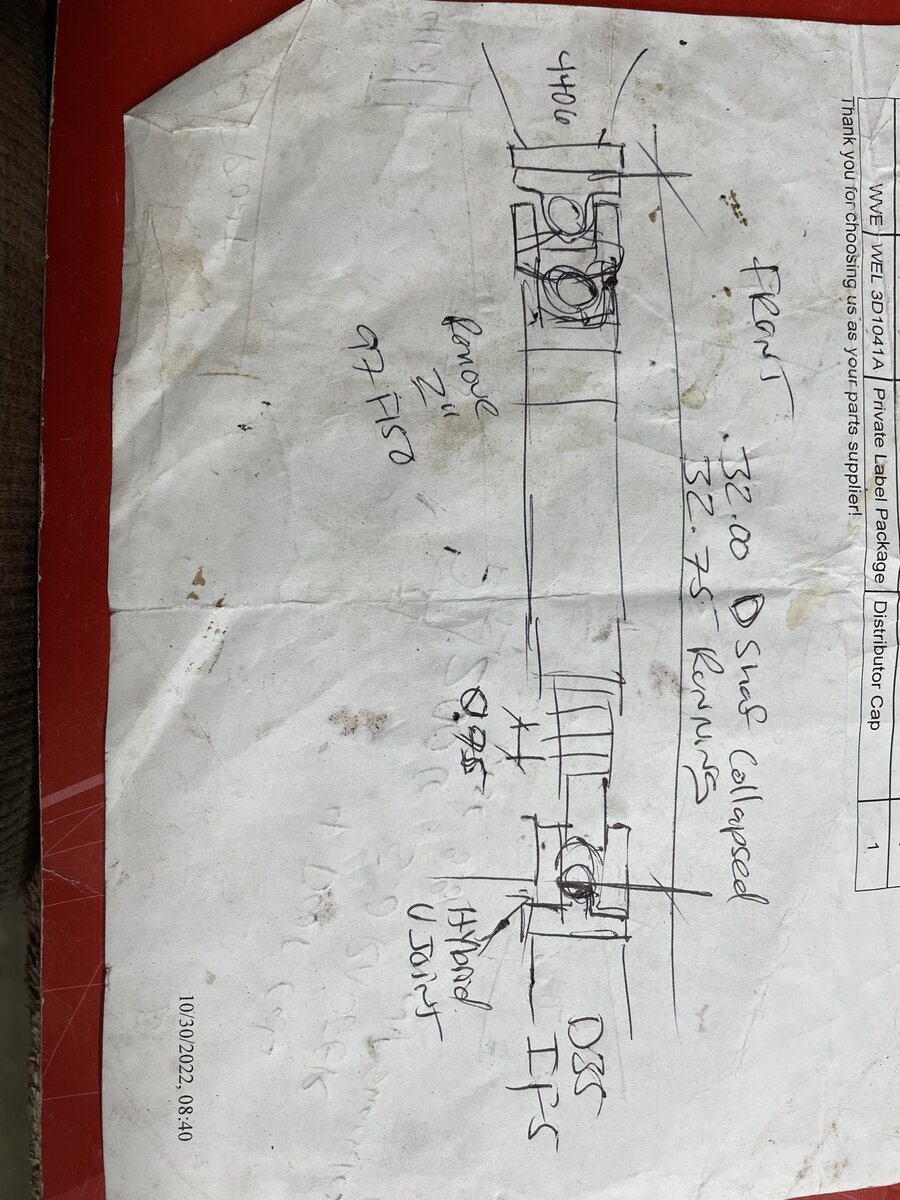

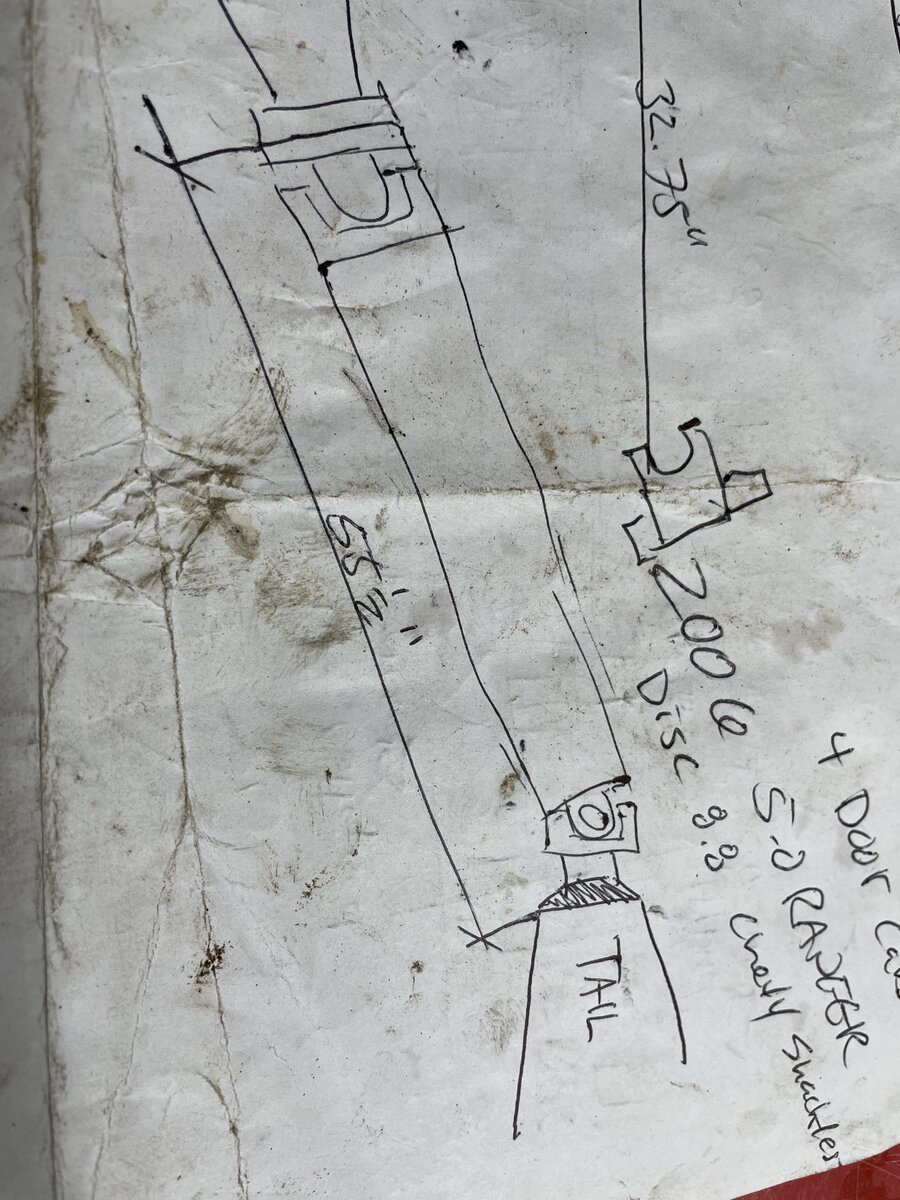

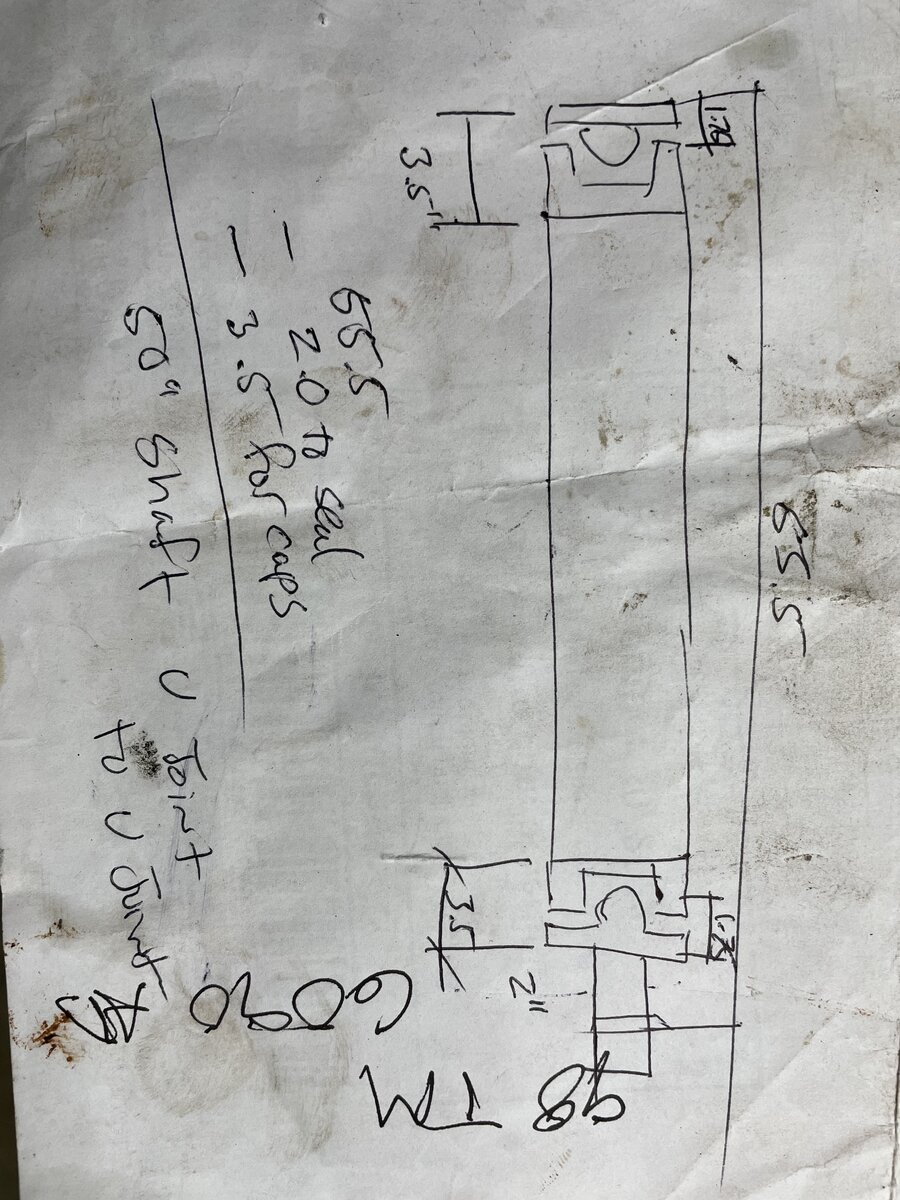

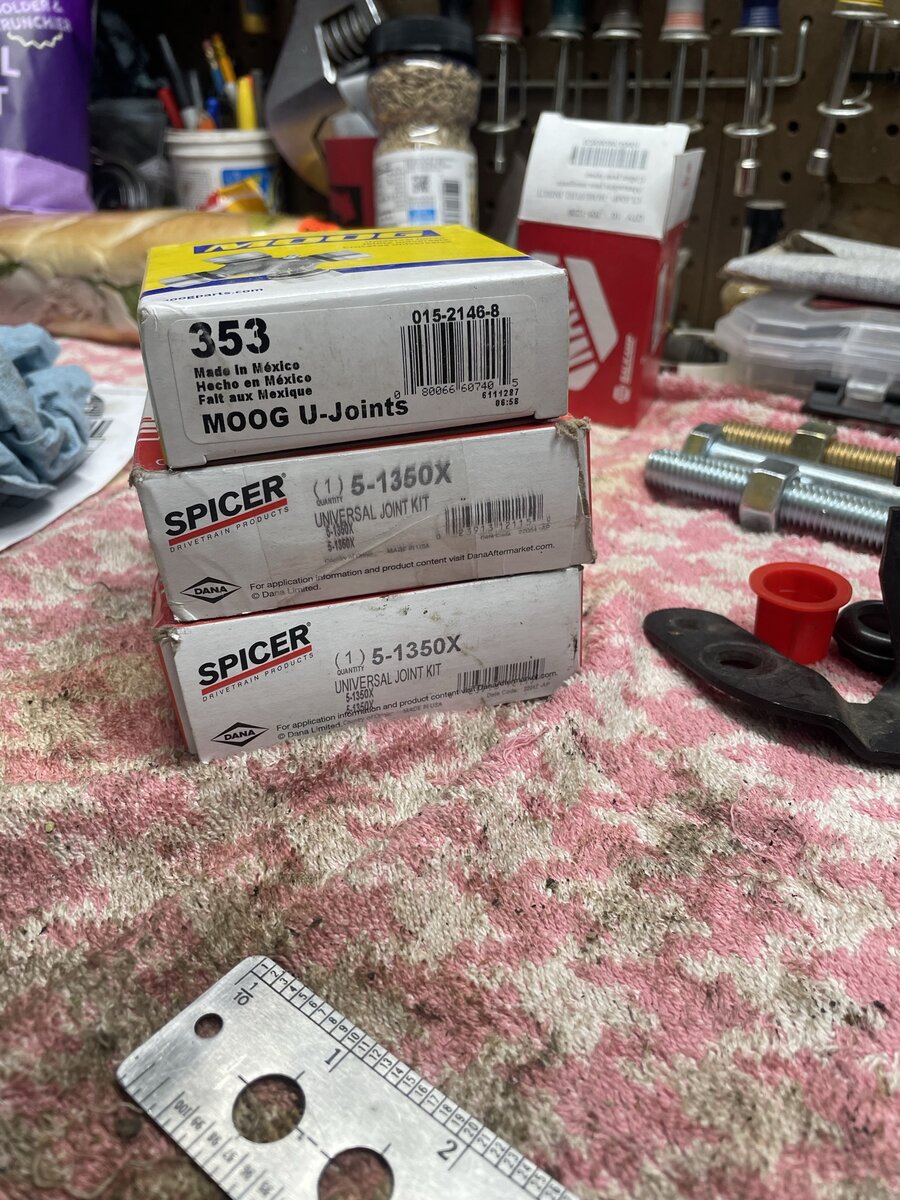

My chicken scratch notes from measuring for shafts. I

Love posting this behind the scenes stuff

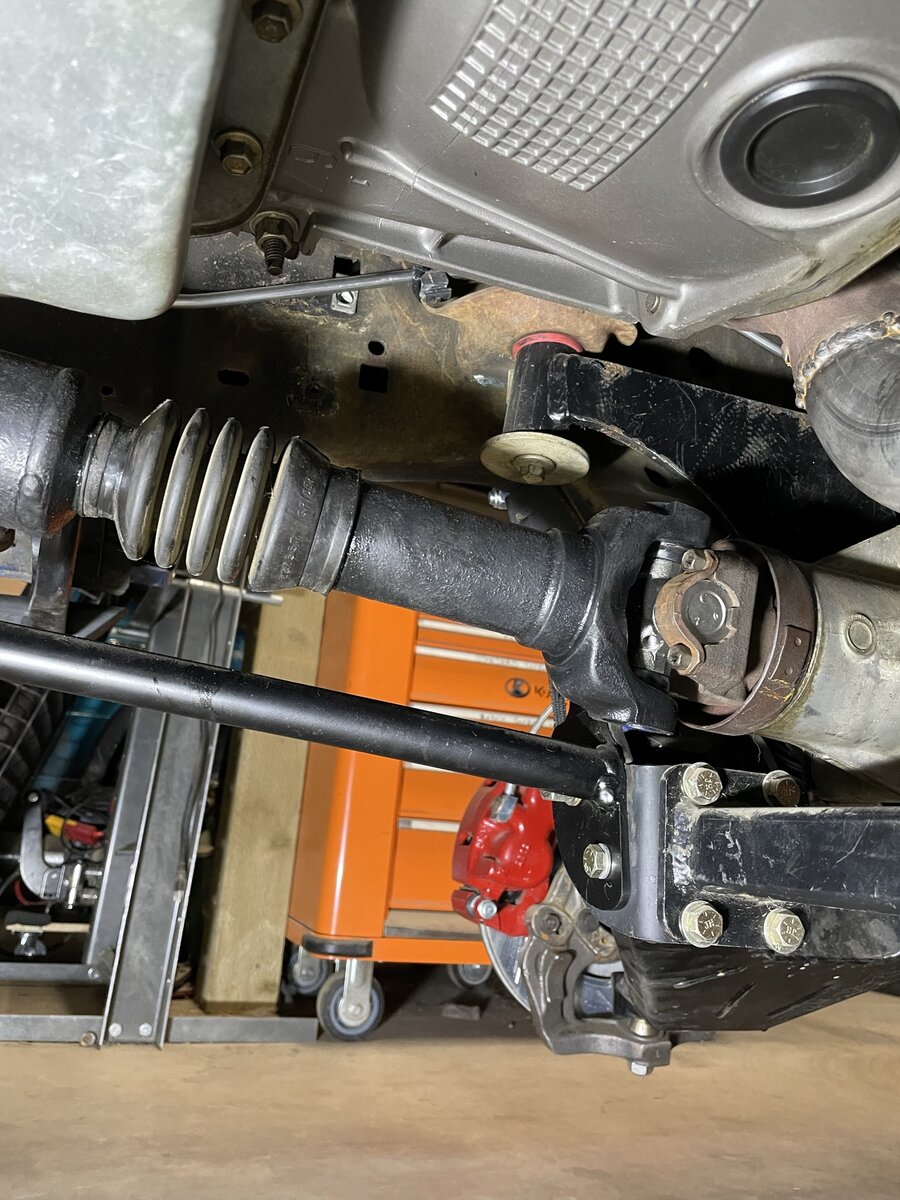

Lets check out the driveshafts

I scored on some 1997 F1250 driveshafts locally

I shortened them and rebuilt with new U joints

Front

All parts kept in phase and square during re assembly

Beware the pink work bench towel!! Maybe hard for some viewers to see

Moog conversion u joint, they did not have a spicer conversion joint in town. Moog will work

Any “high welds” were knocked down with grinder. shafts cleaned, painted, assembled. The big metal “ring” on the rear shaft was removed (with torch) for clearance of the ranger crossmember

Done!!

My chicken scratch notes from measuring for shafts. I

Love posting this behind the scenes stuff

Lets check out the driveshafts

I scored on some 1997 F1250 driveshafts locally

I shortened them and rebuilt with new U joints

Front

All parts kept in phase and square during re assembly

Beware the pink work bench towel!! Maybe hard for some viewers to see

Moog conversion u joint, they did not have a spicer conversion joint in town. Moog will work

Any “high welds” were knocked down with grinder. shafts cleaned, painted, assembled. The big metal “ring” on the rear shaft was removed (with torch) for clearance of the ranger crossmember

Done!!

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

No! If it need balancing then we can have it done. Shafts were balanced before I get them, as long as we keep them in phase and square I have not had an issue with like the last 4-5 trucks I have done. They are all still on the road. The “driveline” shop I used to pay to do this for me ($400-600+ now??)! They don’t even balance them either… I figured I could do a better job myself and save the money. So far I have been right!

We did find a driveshaft shop about 2 hour drive he is willing to help us for a fair price and he can balance. I’m happy with this method so far. There are some YouTube’s that show us how to redneck balance if there ends up being a wobble (there won’t)

We did find a driveshaft shop about 2 hour drive he is willing to help us for a fair price and he can balance. I’m happy with this method so far. There are some YouTube’s that show us how to redneck balance if there ends up being a wobble (there won’t)

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

The instrument cluster

Now that I have a working 2005 cluster I wanted to make it appear to be his original 07 cluster with the white faces

So I took both clusters apart and swapped the good looking parts over

Everything cleaned and dusted ready for assembly. The needles are only pressed on lightly because they will need adjusting when power is applied

Much better to have a nice clean cluster

I really like these late model units, the 2005 is the last year with wiring inputs, after this they all went can bus and we will need some sort of can bus emulator to make customizations to any of the gauges or warning lights

Now that I have a working 2005 cluster I wanted to make it appear to be his original 07 cluster with the white faces

So I took both clusters apart and swapped the good looking parts over

Everything cleaned and dusted ready for assembly. The needles are only pressed on lightly because they will need adjusting when power is applied

Much better to have a nice clean cluster

I really like these late model units, the 2005 is the last year with wiring inputs, after this they all went can bus and we will need some sort of can bus emulator to make customizations to any of the gauges or warning lights

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- August 3, 2000

- Messages

- 35,107

- Reaction score

- 12,049

- City, State

- NORTH IDAHO, 7B

- Year, Model & Trim Level

- B2 "Slightly" Modified

- Callsign

- FOURTEN

Yes you can see the fork in the pictures. These late model needles take ALOT more force to remove then the old ones I was worried the first time I was going to break something pulling really hard.

The 02 sensor bung is back a few pages lol lol I’ll show you

The 02 sensor bung is back a few pages lol lol I’ll show you