So, I was never actually able to get rid of that random misfire code p0300. Fuel trims looked the same on both banks, and tried everything I could think of except for inviting a priest over for an exorcism.

I am quite certain its the cam causing the issue. The fix? I told the pcm to avoid misfire checking below 1500 rpm. Problem solved. Iv'e been driving off and on for the last 6 or so weeks with no check engine light on.

The tuning never stops. I tried getting more mid range by adding more timing in the lower rpm's, but the J&S knock sensor told me otherwise

. The cam card says to use a minimum 3000 rpm stall converter, and I am going to say they were not lying. My 2800 stalls to fast for a super quick off the line launch. One word....****ty.

Someone have a 3200 stall locking torque converter for a 4r70w lying around?

On the other side of things, even part throttle at 3000 rpm boost is on and the old girl pulls really hard. Hard enough that I'm going to have to be really careful over winter.

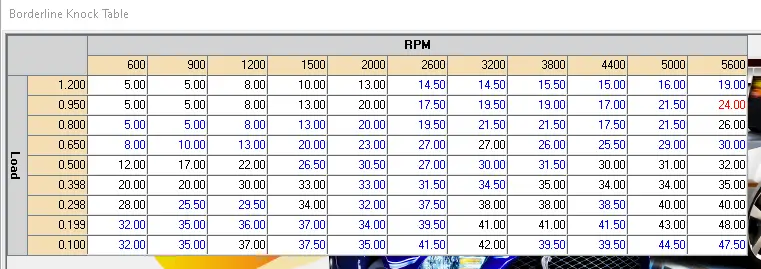

For whatever reason, I seem to be able to add quite a bit of timing above 5600rpm. I'm still playing with that number, slowly inching up up to where the knock sensor lights up and tells me to back off. I think the water/meth is letting me do this. But, notice what my timing table looks like. At peak torque, I don't have much timing. Also, look at the lower rpm's. I thought some of the area's that the knock sensor was detecting detonation was a false reading, but I remove a bit of timing and the sensor doesn't detect knock in that area anymore. How do you argue with that?

On a side note, I found a used SCTx4 for my mustang. I know its a different motor, but that same trans. Just loading the base tune and then adding value files for the 87 octane fuel and the 4r70w performance value file it really woke that little car up. It just made me think how hard it is to make our trucks fast, then I do something super quick and easy to the car and make a real noticeable difference. I think were out of summer, but I'm hoping I can get the tank low enough to fill it with 91, and load the 91 octane value file. There's way more timing in the 91 file, so I'm curious if I'd feel a difference.