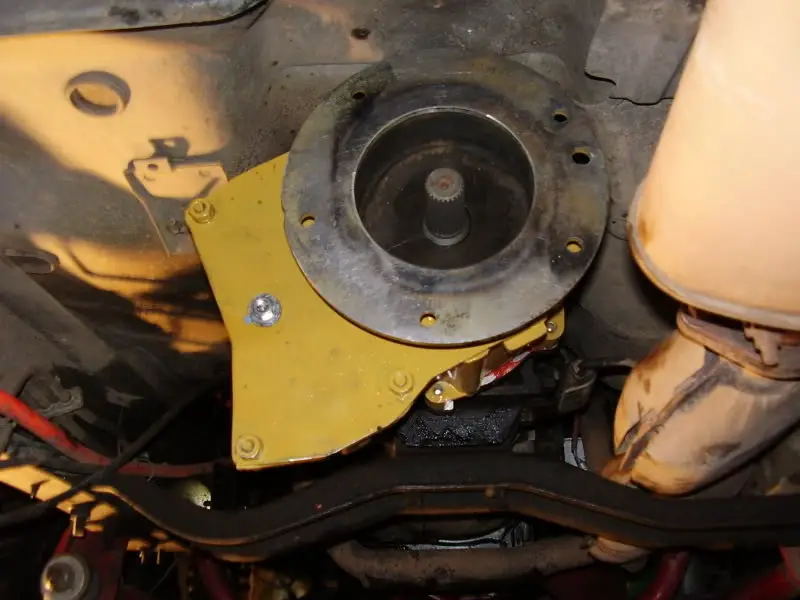

I finally got around to getting that doubler in and getting most of it squared away. Swapped out rad arms and got new mounts for them. New tranny cross member that doubles as a skid. The cross member supports both eh tranny and the doubler. With that much added leverage on an aluminum housing it wasn't a bad idea to put in a little support. Now it's got clean lines with a flat belly. Rad arms now can act as sliders and everything is up and out of the way. Total crawl ratio is about 120:1. There are a few more things to finish up, need to get the drivelines build and it should be ready to go.

Also modified the coil bucket. Get a bit more flex out of it. I'll need to ramp it again to get definite numbers, but limit straps are in the picture. I will need to get some new shocks as the current are not the proper length and are shot. On with the pics.

Also modified the coil bucket. Get a bit more flex out of it. I'll need to ramp it again to get definite numbers, but limit straps are in the picture. I will need to get some new shocks as the current are not the proper length and are shot. On with the pics.

I forget, were you part of the last group buy, or did you get it from someone who was?

I forget, were you part of the last group buy, or did you get it from someone who was?