-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

- Forums

- New Members - Photo Gallery- Explorer Registries

- Explorer Photos Registries & Gallery

- Elite Explorer Registry

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Black Hole

- Thread starter gmanpaint

- Start date

Post

number 3327

has been selected as best answered.

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

I started looking around for simple obvious issues to track down that 1309 code, before replacing parts. Thinking the cam sensor might be the issue, or the little spinning flag, on the cam synchronizer itself, is bent/broke. Still need to tear into that. My hands a bit big to reach it without removing the coil packs first.

I found a few more things to fix while looking closely at the engine compartment. Will get to those later. Lots of posts coming soon on past, present & future work to get this thread up to speed.

I found a dr side plug wire boot rubbing against the steering shaft collar. It moves when the wheel is turned. So.... Is this a common issue with a 3" body lift and the 5.0's? OR.. is this just the aftermarket wires used, and the boots are just too long with the Orielly brand they installed?

If I can't find a shorter boot, I really do not want to dish out $300 on a Flaming River steering shaft, just to move the collar away from the boot. Surely, somebody else has ran into this before?

I will try to spray water on the wires tonight, and look for an arc.

Found they used Autolite plugs, not Motorcraft as asked. Not sure if these are as good/reliable or not.

I found a few more things to fix while looking closely at the engine compartment. Will get to those later. Lots of posts coming soon on past, present & future work to get this thread up to speed.

I found a dr side plug wire boot rubbing against the steering shaft collar. It moves when the wheel is turned. So.... Is this a common issue with a 3" body lift and the 5.0's? OR.. is this just the aftermarket wires used, and the boots are just too long with the Orielly brand they installed?

If I can't find a shorter boot, I really do not want to dish out $300 on a Flaming River steering shaft, just to move the collar away from the boot. Surely, somebody else has ran into this before?

I will try to spray water on the wires tonight, and look for an arc.

Found they used Autolite plugs, not Motorcraft as asked. Not sure if these are as good/reliable or not.

- Joined

- September 16, 2002

- Messages

- 9,319

- Reaction score

- 1,152

- City, State

- Virginia Beach, Va

- Year, Model & Trim Level

- 00 4x4 Mounty

The 3rd plug back has the longest wire. It swoops back around to a bracket that connects to the rear head bolt. I run regular autolite copper plugs with Motorcraft wires.

- Joined

- June 17, 2004

- Messages

- 24,495

- Reaction score

- 5,098

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

Ditto, Autolite plugs are a good brand also. The plug wire holders are often broken from age and handling, they are super brittle. It's usually no trouble to use a wire tie to hold the wires to something, and away from the exhaust etc.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

Thanks for the pics @boominXplorer !

The boot that hits the steering shaft is the 2nd plug (#6 I believe) to the front.

It looks like the Motorcraft boots are shorter than these cheapo Omnispark wires are. The wire hold downs/clips are all missing pretty much. I found one on the valve cover tho. lol

I looked up the plugs, and they are the Autolite platinum's. I think I will go buy a set of Motorcraft wires, and compare boots on them.

Different subject.... I disconnected the battery while I was working under the hood. Modules are all drained now. A few hours later, I buttoned it all back up, ran the engine for 15 mins, and the cel never came back on. Revved it to 2000 rpm's, and held it for a minute, and still nothing. Hmm....Crazy rig.

The boot that hits the steering shaft is the 2nd plug (#6 I believe) to the front.

It looks like the Motorcraft boots are shorter than these cheapo Omnispark wires are. The wire hold downs/clips are all missing pretty much. I found one on the valve cover tho. lol

I looked up the plugs, and they are the Autolite platinum's. I think I will go buy a set of Motorcraft wires, and compare boots on them.

Different subject.... I disconnected the battery while I was working under the hood. Modules are all drained now. A few hours later, I buttoned it all back up, ran the engine for 15 mins, and the cel never came back on. Revved it to 2000 rpm's, and held it for a minute, and still nothing. Hmm....Crazy rig.

- Joined

- June 17, 2004

- Messages

- 24,495

- Reaction score

- 5,098

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

That's good, the more you drive it, and the more you work on it, makes it happier. I hate working on a car that doesn't run(needs a lot of stuff done).

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

I found my brand new set of 4.0 plug wire trail spares. Compared the boots, and the 4.0 is way shorter in length than the 5.0. Probably because of the manifolds, but the space between them looks the same to me. The end of the 5.0 boot is bulkier, and extends further past the internal plug tip. So I swapped them out, and there is now about an inch gap between the boot and the steering column. Fired right up, and no miss, no codes.

Gray is 5.0

Black is 4.0

I did find a metal bracket hanging loose off this wire behind the A/C compressor. It is fairly big and U shaped with a hooked end. I can tell it is supposed to bolt onto something to hold the wires, but no idea where. I wish I had another 2nd gen 5.0 to look at to compare for all this crap I'm finding.

Gray is 5.0

Black is 4.0

I did find a metal bracket hanging loose off this wire behind the A/C compressor. It is fairly big and U shaped with a hooked end. I can tell it is supposed to bolt onto something to hold the wires, but no idea where. I wish I had another 2nd gen 5.0 to look at to compare for all this crap I'm finding.

- Joined

- June 17, 2004

- Messages

- 24,495

- Reaction score

- 5,098

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

Good find, the 4.0 wires will work if the ends and length match, good info. I think there is a plug wire hold down behind the AC compressor, I don't recall what it looks like.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

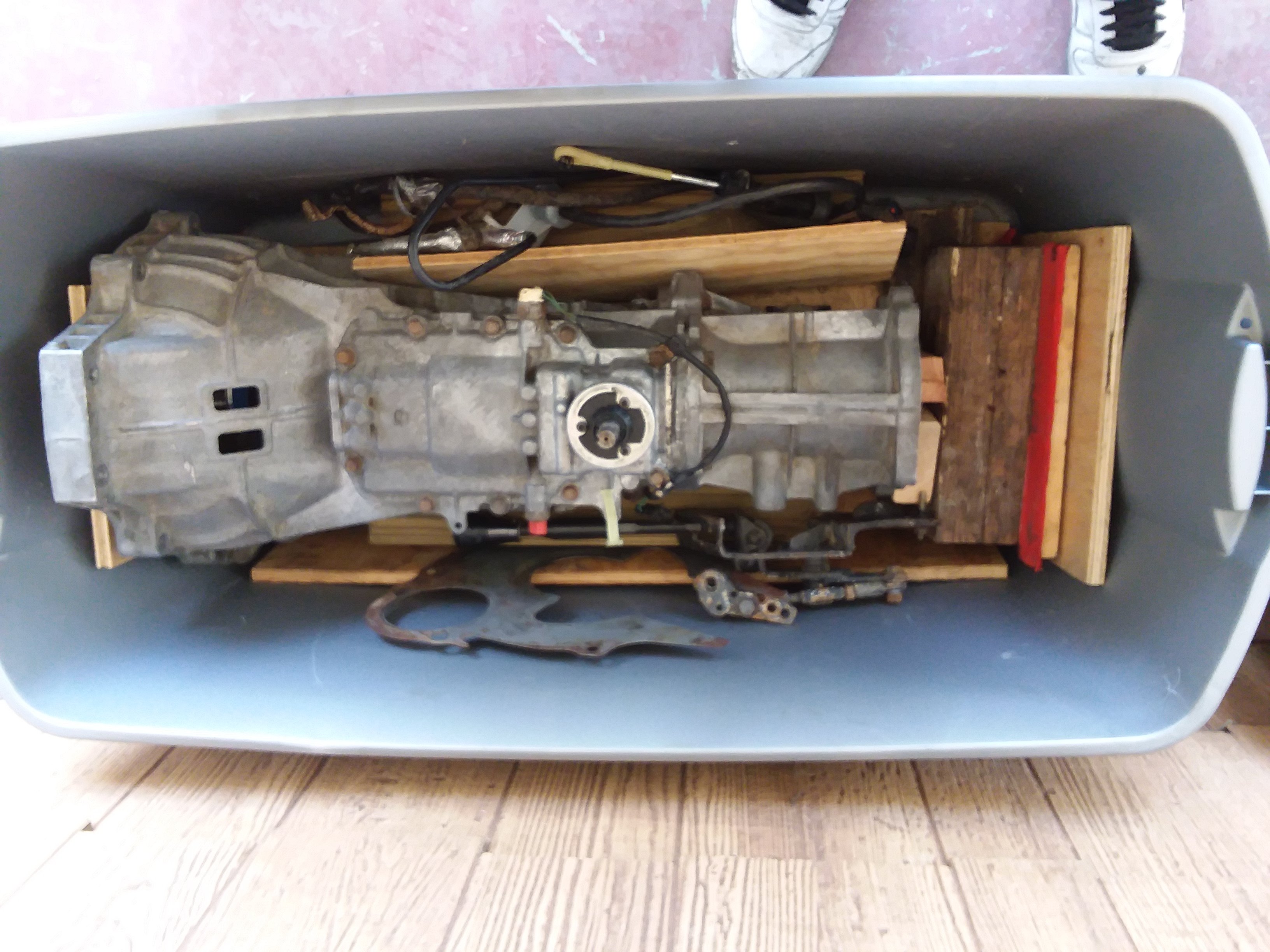

Good Used parts go neglected everyday in this world, and it can be avoided. (sad violins playing)

They get tossed aside, left out in the cold, put on a shelf, walked upon, strangled by vegetation, peed on by stray animals, and simply forgotten about.

For less than a cup of gourmet coffee/day, ( for 1.2 years) you could make a significant improvement to their way of life. (Insert Images of crying babies and sad old people here)

Free them from isolated captivity, bring them back together as one happily united family, and being productive once again.

They get tossed aside, left out in the cold, put on a shelf, walked upon, strangled by vegetation, peed on by stray animals, and simply forgotten about.

For less than a cup of gourmet coffee/day, ( for 1.2 years) you could make a significant improvement to their way of life. (Insert Images of crying babies and sad old people here)

Free them from isolated captivity, bring them back together as one happily united family, and being productive once again.

- Joined

- September 16, 2002

- Messages

- 9,319

- Reaction score

- 1,152

- City, State

- Virginia Beach, Va

- Year, Model & Trim Level

- 00 4x4 Mounty

LMFAO! I now feel the need to buy them and I don't even need them lol

- Joined

- June 17, 2004

- Messages

- 24,495

- Reaction score

- 5,098

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

Me too, I'm not a manual trans guy, but those look good in the big tubs. I bought one of those big ones to ship my intake and some parts to Jon, to shine up many years ago. I use it now since he shipped it all back, for a paper recycling tub. Those are heavy when you get them full.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

Between work getting crazy, my aching body, and a few different projects going on at the same time, I managed to find a couple hours tonight for this rig.

The Steel Uniballs have some rust on the BTF UCA's I installed a little less than 2 years ago. Rig has only put on a couple thousand miles in that time, and these arms have never been used in the last 2 winters, so no road salt/chemicals. Must be the high humidity here.

So I called Brandon (BTF), and asked him if he had any Stainless versions. He hooked me up, and had them to me in a few days. I managed to get one side installed tonight. The 95, (or this rig) has tight arm mount tabs, and getting the arms on, took a big dead blow, and many, many whacks to force them on. Knowing that, I left the arms on, and removed the uniball, using my big ball joint C clamp. After removing the C clip, I had to use a socket to push the ball out of the arm, and the impact on the clamp.

I cleaned everything up with some emery cloth, wiped it all down, and blew it out, with the air gun. I quickly learned that the clamp wasn't going to push it back in there. Think frozen Lower ball joint. After putting a thin layer of red synthetic grease, in the socket, and the new uniball, I hammered it in with the spacers from the ball joint clamp kit, and Thor's Hammer. I had to get after it. lol It seemed like it wasn't going to go in, then it did. Phew!!

I will be working on it some more over the weekend, to finish up the other side, and lot's more. EF member @TheBlackPearl (Kurt) and his buddy Jacob, are coming over to help me get a bunch knocked out, so we can all hit the trails next weekend. By Monday, there should be a few more progress posts here.

The 2 yr old old crusty Uniball.

Center Post before clean up. (Forgot to take a pic after)

New 1" Stainless Uniball. PN is stamped on it for anybody searching.

The ring on top that needs to be removed for swap.

Can't believe it got that bad, that fast. Might be from sitting so much, humidity, or a combo? At least the sleeve and post clean up real nice & easy.

The Steel Uniballs have some rust on the BTF UCA's I installed a little less than 2 years ago. Rig has only put on a couple thousand miles in that time, and these arms have never been used in the last 2 winters, so no road salt/chemicals. Must be the high humidity here.

So I called Brandon (BTF), and asked him if he had any Stainless versions. He hooked me up, and had them to me in a few days. I managed to get one side installed tonight. The 95, (or this rig) has tight arm mount tabs, and getting the arms on, took a big dead blow, and many, many whacks to force them on. Knowing that, I left the arms on, and removed the uniball, using my big ball joint C clamp. After removing the C clip, I had to use a socket to push the ball out of the arm, and the impact on the clamp.

I cleaned everything up with some emery cloth, wiped it all down, and blew it out, with the air gun. I quickly learned that the clamp wasn't going to push it back in there. Think frozen Lower ball joint. After putting a thin layer of red synthetic grease, in the socket, and the new uniball, I hammered it in with the spacers from the ball joint clamp kit, and Thor's Hammer. I had to get after it. lol It seemed like it wasn't going to go in, then it did. Phew!!

I will be working on it some more over the weekend, to finish up the other side, and lot's more. EF member @TheBlackPearl (Kurt) and his buddy Jacob, are coming over to help me get a bunch knocked out, so we can all hit the trails next weekend. By Monday, there should be a few more progress posts here.

The 2 yr old old crusty Uniball.

Center Post before clean up. (Forgot to take a pic after)

New 1" Stainless Uniball. PN is stamped on it for anybody searching.

The ring on top that needs to be removed for swap.

Can't believe it got that bad, that fast. Might be from sitting so much, humidity, or a combo? At least the sleeve and post clean up real nice & easy.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

While I had the arm apart, I pulled the shock, and added a heavier coil, to make up for the added weight of the 5.0L. Went up another 50 lbs.

Ok, so this isn't just any coil, it was gussied up by none other than Turdle powder. Thanks Jon, it came out sick AF! Pics really don't do it justice. Screens and the camera lens do not catch how cool these Dark shadow Cherry translucent metallic coils actually look. They go from dark cherry to dark blood red in the sunlight.

I also installed some pretty neat washers made by QA1. A set of 3 washers, and the middle washer has a bunch of tiny roller pin bearings in it. When you turn the coil nuts, they spin instead of the coil, and make adjusting super simple. Once adjusted, the 2nd nut locks it all into place. If anybody has used coil overs for lift, they understand what I'm talking about. You get to a certain point tightening them, and the coils start to turn, making it harder to keep going. Wish I had these from the start!

I will post a pic of them installed after this weekend. For now, here is a teaser.

Ok, so this isn't just any coil, it was gussied up by none other than Turdle powder. Thanks Jon, it came out sick AF! Pics really don't do it justice. Screens and the camera lens do not catch how cool these Dark shadow Cherry translucent metallic coils actually look. They go from dark cherry to dark blood red in the sunlight.

I also installed some pretty neat washers made by QA1. A set of 3 washers, and the middle washer has a bunch of tiny roller pin bearings in it. When you turn the coil nuts, they spin instead of the coil, and make adjusting super simple. Once adjusted, the 2nd nut locks it all into place. If anybody has used coil overs for lift, they understand what I'm talking about. You get to a certain point tightening them, and the coils start to turn, making it harder to keep going. Wish I had these from the start!

I will post a pic of them installed after this weekend. For now, here is a teaser.

- Joined

- June 17, 2004

- Messages

- 24,495

- Reaction score

- 5,098

- City, State

- Knoxville, TN

- Year, Model & Trim Level

- 98 Limited AWD 302

Beautiful. Take care of those coil springs, they'll look good on my truck. I like the finish on the UCA's too, is that chrome or a SS polished maybe?

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

The arms came in a rattle can gun metal tan. I stripped them clean, and used POR15 gloss black, and silver /red on the name tags. They need some touch up. I am going to paint the knuckles, and will do it then.

So we got the new hood on. It makes the rest of the rig look like a turd. Hasn't had a bath in 6 months, and needs some love. After the hood is fully cured, I can do the final buff & polish on all of it.

My buddy who painted it, didn't see the picture I sent him, for the Black Hole graphic to work off of, and did it, to what he thought I explained. It's not what I expected, but it's done, and done. It's different, and unique, that's for sure.

The stripes are a dark cherry, with silver pin stripes, and a satin clear over them. The rear hatch will be getting the matching stripes some time in the near future.

So we got the new hood on. It makes the rest of the rig look like a turd. Hasn't had a bath in 6 months, and needs some love. After the hood is fully cured, I can do the final buff & polish on all of it.

My buddy who painted it, didn't see the picture I sent him, for the Black Hole graphic to work off of, and did it, to what he thought I explained. It's not what I expected, but it's done, and done. It's different, and unique, that's for sure.

The stripes are a dark cherry, with silver pin stripes, and a satin clear over them. The rear hatch will be getting the matching stripes some time in the near future.

WormsExplorer

Explorer Addict

- Joined

- February 14, 2015

- Messages

- 1,433

- Reaction score

- 603

- Location

- Brinnon, WA

- City, State

- Brinnon, WA

- Year, Model & Trim Level

- 94 Ford Explorer

Looks awesome

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

- Joined

- August 1, 2008

- Messages

- 11,618

- Reaction score

- 2,208

- City, State

- MO MO

- Year, Model & Trim Level

- 94 & 95 XLT's

Went back at this afternoon, and got the new dr side coil, and new SS Uniball installed. Re-set the limit strap to stop the arm, before hits the frame.

Took it for a ride to settle the coils, and I need to adjust them to get the ride height back. I just used the measure from the previous coils to give me a starting point. Unfortunately, the rains started, and I had to call it a day. I will get them dialed in one day after work this week.

Took it for a ride to settle the coils, and I need to adjust them to get the ride height back. I just used the measure from the previous coils to give me a starting point. Unfortunately, the rains started, and I had to call it a day. I will get them dialed in one day after work this week.

Similar threads

- Replies

- 5

- Views

- 13,381

- Replies

- 11

- Views

- 2,680

- Replies

- 3

- Views

- 305

- Replies

- 6

- Views

- 2,544