BenMar

Elite Explorer

- Joined

- July 25, 2010

- Messages

- 40

- Reaction score

- 0

- City, State

- Iowa City , Iowa

- Year, Model & Trim Level

- '96 XLT

Great project truck - it'll be worth the work !

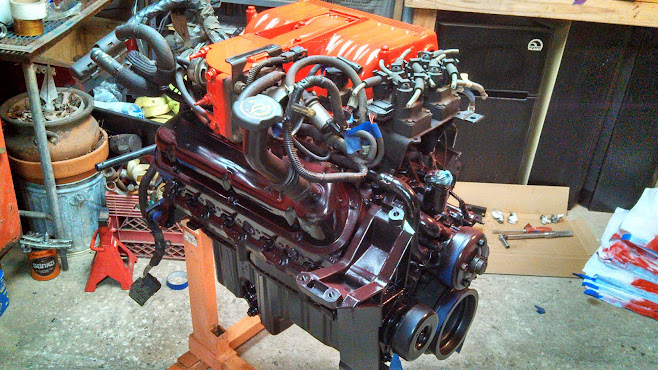

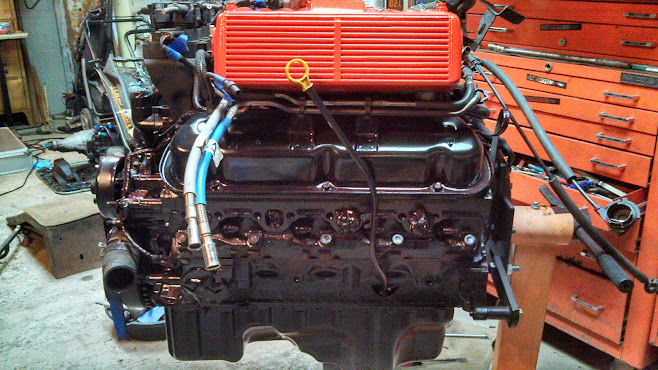

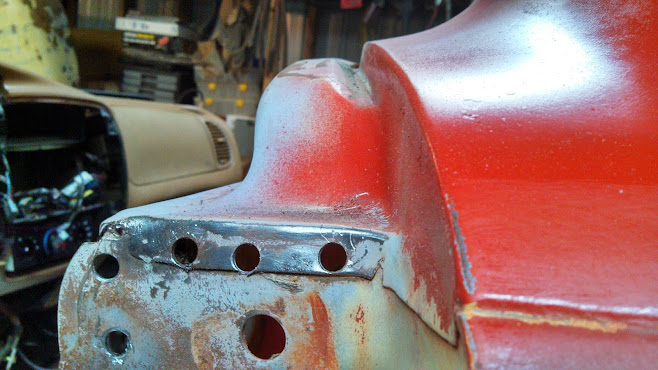

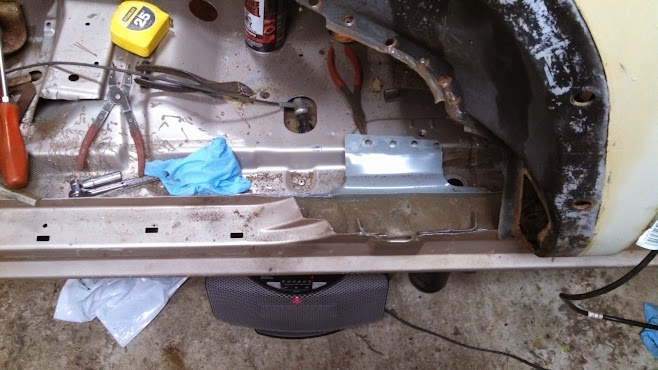

I've enjoyed reading thru the posts , and it's clear that many others have an interest in using the Explorer chassis under different vehicles. I found a '96 Explorer with 61,000 miles , that had been sideswiped by a semi while parked on a city street. Damage all high on the body. Saved it from the crusher ! Then placed a Studebaker body, with 64,000 miles on it, onto the Explorer chassis. Hardest part was sorting out the miles and miles of Ford wiring ! Had to use 1.5" wheel spacers to get the track out wide enough. This truck drives and handles like new.

If you guys are interested , I can also post pics of the chassis after it was restored, but before the body was placed on it. Just don't know if the interest is there ? Thanks - Best of luck to you.

I've enjoyed reading thru the posts , and it's clear that many others have an interest in using the Explorer chassis under different vehicles. I found a '96 Explorer with 61,000 miles , that had been sideswiped by a semi while parked on a city street. Damage all high on the body. Saved it from the crusher ! Then placed a Studebaker body, with 64,000 miles on it, onto the Explorer chassis. Hardest part was sorting out the miles and miles of Ford wiring ! Had to use 1.5" wheel spacers to get the track out wide enough. This truck drives and handles like new.

If you guys are interested , I can also post pics of the chassis after it was restored, but before the body was placed on it. Just don't know if the interest is there ? Thanks - Best of luck to you.