-

Ford Explorer Community - Maintenance - Modifications - Performance Upgrades - Problem Solving - Off-Road - Street

Explorer Forum Covers the Explorer ST, Explorer Sport, Explorer Sport Trac, Lincoln Aviator,

Mercury Mountaineer, Mazda Navajo, Ford Ranger, Mazda Pickups, and the Ford Aerostar

Register Today It's free!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whitey turns red build thread!

- Thread starter sirhk100

- Start date

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

Przybysz

Well-Known Member

- Joined

- August 29, 2009

- Messages

- 335

- Reaction score

- 0

- City, State

- Its pronounced (Priz-biz)

- Year, Model & Trim Level

- '96 XLT

I'm holding off to sell the whole front clip as one complete kit. It is for sale though.

Link me!

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Slacked a little bit this weekend to be honest... The radius arms I'm using are shorter then the james duff arms but I liked the james duff trans crossmember that was already on red so I cut the radius arms I wanted to use, sleeved them and extended them about 2" longer. I could clean them up and make them so that you could never tell where I modified them but honestly, once they're painted 99% of the people aren't going to notice anyways so I didn't spend much time cleaning them up. They're strong for sure!

Roughly ride height. Obviously still the stock fenders. The fiberglass ones I have on order are 6" flairs.

Roughly what full bump will likely be.

Also rough... That's 17.5" difference between sides though and the shocks should allow it. This isn't final, the upper shock mounts aren't started but that's next. Was just getting ideas of what it would be capable of.

Both sides at full bump.

Roughly ride height. Obviously still the stock fenders. The fiberglass ones I have on order are 6" flairs.

Roughly what full bump will likely be.

Also rough... That's 17.5" difference between sides though and the shocks should allow it. This isn't final, the upper shock mounts aren't started but that's next. Was just getting ideas of what it would be capable of.

Both sides at full bump.

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

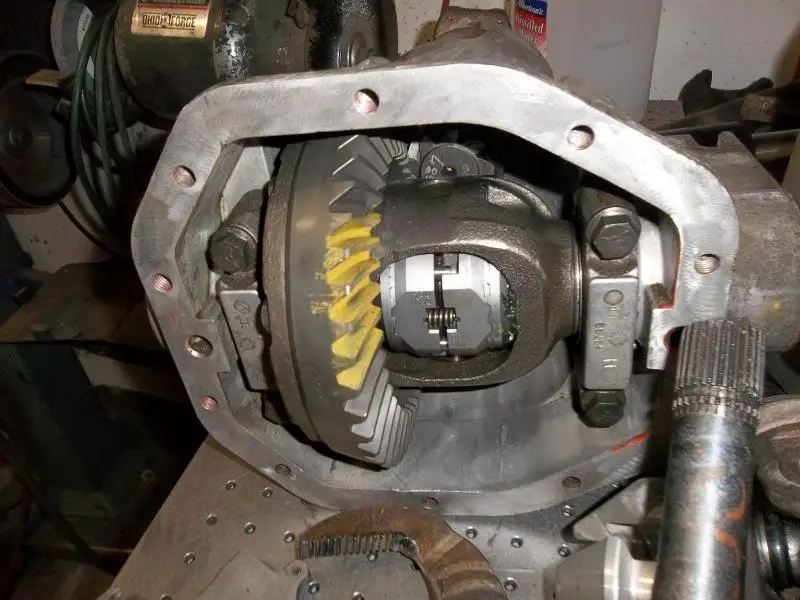

Picking up the front 3rd member today. It already had a brand new set of 4.56 gears in it but I had them toss a locker in it really quick too. I can get that put in, get my longer axles assembled to the outter stubs and slap the whole thing in place to cycle it and check for any clearance of the yokes or the beams for the travel I'm looking for... Couldn't have asked for them to finish that with better timing!!!

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Well parents rolled into town yesterday and will be around for a couple weeks so progress may slow a little bit but even with them around I still managed to get the new longer axles assembled to the short shafts. Tonight's goals are to toss the whole front driveline back into the beams and cycle it to check for u-joint binds and any interference between the beams and the axles.

Oh and yes, I broke my POS harbor freight vice last night too. Whoops... Guess I'll go buy a real one this weekend.

Ready for the front end to do some work...

Oh and yes, I broke my POS harbor freight vice last night too. Whoops... Guess I'll go buy a real one this weekend.

Ready for the front end to do some work...

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

What? Doesn't everyone buy massive jugs of brake fluid? I have a clean brake fluid fetish with my vehicles and change it bi-weekly! LOL

Actually it's a gallon of shock oil. Between the race truck, my prerunner, and this expo with kings front and rear... I buy shock oil in the 5 gallon buckets and then when I'm actually working on them I use 1 gallon jugs cause it's a heck of a lot easier to pour with those then a 5 gallon bucket. I pulled the front coilovers for the expo apart Sunday afternoon to see what was in them for valving so I'd have a starting point and changed oil in them too. Just haven't put the oil away yet. Put it this way, in my driveway... I have 16 shocks total that get rebuilt and serviced as needed, with that many, you learn to do it yourself really fast rather then paying for it to be done! LOL

Actually it's a gallon of shock oil. Between the race truck, my prerunner, and this expo with kings front and rear... I buy shock oil in the 5 gallon buckets and then when I'm actually working on them I use 1 gallon jugs cause it's a heck of a lot easier to pour with those then a 5 gallon bucket. I pulled the front coilovers for the expo apart Sunday afternoon to see what was in them for valving so I'd have a starting point and changed oil in them too. Just haven't put the oil away yet. Put it this way, in my driveway... I have 16 shocks total that get rebuilt and serviced as needed, with that many, you learn to do it yourself really fast rather then paying for it to be done! LOL

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Double posting this a little as I just put it in another thread I have in the driveline section but just in case...

I got the whole front driveline installed last night and started cycling my front suspension last night.

Both sides at full bump, I'm fine...

Both sides at full droop, I'm fine... (once I massaged the center u-joint where the spring is for the extra angle I needed)

Driver side at full bump, pass side full droop, I'm fine...

Driver side at full droop, I start compressing the pass side and about halfway thru the travel the driver side starts lifting. It was a bit late last night when I got to this point and I called it a night shortly after without putting much effort into it but quick glance. It looked like my pass side axle was plunging too deep into the short shaft coming out of the diff at U-joint/yoke pivot. The yoke on the short shaft still has the dust cap in it and I think it's bottoming out into that and causing it to bind and therefore lift the drivers side.

Have people had success popping that dust cap out and just running it open letting the axle plunge thru it assuming it doesn't contact the ujoint itself?

I saw a post by Maniak in another thread where he says his boot has been torn up for quite a while with no problems so I'd have to assume his is exposed to elements and still holding up.

It's been 10+ years since I built my last expo but I for some reason vaguely remember having the same issue with it and having to pop out that dust seal. I'm not 100% though as that was a long time ago...

Any thoughts??? Would love a semi quick reply as this is tonight's project. If I can get it cycling good I'll probably get started on the engine cage tomorrow night so I can get my shocks mounted up...

I got the whole front driveline installed last night and started cycling my front suspension last night.

Both sides at full bump, I'm fine...

Both sides at full droop, I'm fine... (once I massaged the center u-joint where the spring is for the extra angle I needed)

Driver side at full bump, pass side full droop, I'm fine...

Driver side at full droop, I start compressing the pass side and about halfway thru the travel the driver side starts lifting. It was a bit late last night when I got to this point and I called it a night shortly after without putting much effort into it but quick glance. It looked like my pass side axle was plunging too deep into the short shaft coming out of the diff at U-joint/yoke pivot. The yoke on the short shaft still has the dust cap in it and I think it's bottoming out into that and causing it to bind and therefore lift the drivers side.

Have people had success popping that dust cap out and just running it open letting the axle plunge thru it assuming it doesn't contact the ujoint itself?

I saw a post by Maniak in another thread where he says his boot has been torn up for quite a while with no problems so I'd have to assume his is exposed to elements and still holding up.

It's been 10+ years since I built my last expo but I for some reason vaguely remember having the same issue with it and having to pop out that dust seal. I'm not 100% though as that was a long time ago...

Any thoughts??? Would love a semi quick reply as this is tonight's project. If I can get it cycling good I'll probably get started on the engine cage tomorrow night so I can get my shocks mounted up...

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

So with the "problem" post above looking for advice... Here's my update...

Got the front 3rd, and axles in place last night. Started cycling the front end and well, the story is above.

This morning though I had to run across town for work and well, it worked out great cause I needed to get over there today after work anyways so 2 birds, 1 stone... While on my trip I picked up my new front fiberglass fenders so I've got those in hand now. I also got my tabs for the upper shock mounts on the engine cage that I'll hopefully be ready for maybe tomorrow night even or this weekend. Picked up cans to mount my front hydro bumps in. I also picked up some plates I had plasma cut for my passenger side steering swinger when I get to that point hopefully next week if things go well over the next few days. On top of all that I picked up a simple clamp to put on the axle for the spring people run on the pass side axle as a make shift c-clip eliminator. So basically got my hands on some decent parts this morning!

Tonights plans, spend some time with the parents and then hopefully get the axle binding issue I stumbled on last night figured out! If I can do that I'll still be very happy!!!! If that happens with time left before bed I'll probably pop the tie rod off my pitman arm and get going on my parts list for my steering system. I'm lagging on that bad and wanted to order that stuff a couple days ago. It may cause a delay on the front end completion but in the overall grand picture it won't be a big deal cause if I have to stop on the front end progress waiting for parts I still have more then enough work to keep me busy on the interior, mounting front fenders, buttoning up the final details on the rear fenders, etc... All stuff that needs to get done one way or another before I call it "done".

Got the front 3rd, and axles in place last night. Started cycling the front end and well, the story is above.

This morning though I had to run across town for work and well, it worked out great cause I needed to get over there today after work anyways so 2 birds, 1 stone... While on my trip I picked up my new front fiberglass fenders so I've got those in hand now. I also got my tabs for the upper shock mounts on the engine cage that I'll hopefully be ready for maybe tomorrow night even or this weekend. Picked up cans to mount my front hydro bumps in. I also picked up some plates I had plasma cut for my passenger side steering swinger when I get to that point hopefully next week if things go well over the next few days. On top of all that I picked up a simple clamp to put on the axle for the spring people run on the pass side axle as a make shift c-clip eliminator. So basically got my hands on some decent parts this morning!

Tonights plans, spend some time with the parents and then hopefully get the axle binding issue I stumbled on last night figured out! If I can do that I'll still be very happy!!!! If that happens with time left before bed I'll probably pop the tie rod off my pitman arm and get going on my parts list for my steering system. I'm lagging on that bad and wanted to order that stuff a couple days ago. It may cause a delay on the front end completion but in the overall grand picture it won't be a big deal cause if I have to stop on the front end progress waiting for parts I still have more then enough work to keep me busy on the interior, mounting front fenders, buttoning up the final details on the rear fenders, etc... All stuff that needs to get done one way or another before I call it "done".

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

I haven't made the leap out of the stone age yet and am still rocking like a 6 year old flip phone with a camera that is beyond trashed but hey... Here's some fuzzy fenders for the front end!

- Joined

- February 8, 1999

- Messages

- 35,467

- Reaction score

- 4,547

- City, State

- Wayoutin, Aridzona

- Year, Model & Trim Level

- '93 XL '20 ST

- Callsign

- AB7FH

If I remember right I ended up welding my cap in place

Can't say I recall anyone running without the cap, but that doesn't mean much... With all of the builds I have seen here it's hard to keep anything straight!!

Can't say I recall anyone running without the cap, but that doesn't mean much... With all of the builds I have seen here it's hard to keep anything straight!!

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Darn it!!! Forgot my camera... No pictures today.

The axle definitely plunged thru the yoke by about 1/8" or so. It was a combo of that plus forgetting that the window on the passenger beam would possibly interfere. I've got it almost to where I like it but still need to trim more. I've seen a lot of them trimmed out but I've got a feeling what I might be doing tonight will possibly be a little different then most at least. Has anyone actually physically needed the axle to drop down thru the beam a little bit? I'm already trimmed flush with the bottom of my beam and to the best of my calculations I still need to allow the axle another 1/4" or so of room to drop. This would be pretty easy except for the threaded bung for the lower radius arm inside the beam. I'll figure something out on it tonight but basically I'm close... I'm looking to get the last 2" or so of droop out of the drivers side beam and then I'm golden.

The axle definitely plunged thru the yoke by about 1/8" or so. It was a combo of that plus forgetting that the window on the passenger beam would possibly interfere. I've got it almost to where I like it but still need to trim more. I've seen a lot of them trimmed out but I've got a feeling what I might be doing tonight will possibly be a little different then most at least. Has anyone actually physically needed the axle to drop down thru the beam a little bit? I'm already trimmed flush with the bottom of my beam and to the best of my calculations I still need to allow the axle another 1/4" or so of room to drop. This would be pretty easy except for the threaded bung for the lower radius arm inside the beam. I'll figure something out on it tonight but basically I'm close... I'm looking to get the last 2" or so of droop out of the drivers side beam and then I'm golden.

crazyflights

Explorer Addict

- Joined

- August 31, 2008

- Messages

- 2,257

- Reaction score

- 22

- City, State

- St. Joseph, MO

- Year, Model & Trim Level

- 97 1 ton Jeep

I love it ,great work.

I have same jackstands and low pro metal harbor frieght jack.

I have same jackstands and low pro metal harbor frieght jack.

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Well I got my beams to cycle fully. Now I've gotta go back and patch up and build up the passenger side beam to make up for what I did to it! LOL I'll show pictures once it's done... But for now...

Hanging on the limit strap hiding behind the brakeline in this picture...

15" higher and fully stuffed into the compressed bumpstop.

And just some overall shots with the front fenders just sitting roughly in place.

Hanging on the limit strap hiding behind the brakeline in this picture...

15" higher and fully stuffed into the compressed bumpstop.

And just some overall shots with the front fenders just sitting roughly in place.

- Joined

- January 28, 2000

- Messages

- 19,704

- Reaction score

- 245

- City, State

- Huntington Beach, CA

- Year, Model & Trim Level

- 1991 Eddie

Your drooped and stuffed pics are the same. Missing the stuffed pic.

Looking good Khris! I like the 1st gen front clip so much more than the 2nd.

Looking good Khris! I like the 1st gen front clip so much more than the 2nd.

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

Your drooped and stuffed pics are the same. Missing the stuffed pic.

Looking good Khris! I like the 1st gen front clip so much more than the 2nd.

Uh yeah I knew that!!! I mean, wait, what are you talking about? No they aren't!!! You're high dude!!! LOL

Whoops!!!

I'm with you on the 1st gen vs. 2nd gen for sure! Considering I've got both in my driveway basically right now I've got the easy comparison and I know I've made the right choice for my tastes at least.

sirhk100

Explorer Addict

- Joined

- December 19, 2000

- Messages

- 1,770

- Reaction score

- 2

- City, State

- las vegas

- Year, Model & Trim Level

- '91

LOL, for anyone that thought I was high or something when I said I needed to make clearance for the axle to pass thru the bottom of the beam, here's proof... LOL this is the situation with my driver side at full droop and passenger at full bump.

You can see I plated the front face and also made that channel to support the bottom of the beam some where the axle is passing thru it. Along with that I have a hidden part on the back side that most won't even notice. It goes almost the full length eventhough it's a little hard to tell. It stops about an inch short of the uniball pivot.

I also got the bumpstops finalized and fully welded.

Officially I'm cycling exactly 15" with 7" of bump and 8" of droop from ride height basically. Shock tabs are cycling 11.5" and I'm running a 12" stroke shock so I should be golden.

Engine cage will start tomorrow afternoon. Have morning breakfast and house project plans with my parents first.

You can see I plated the front face and also made that channel to support the bottom of the beam some where the axle is passing thru it. Along with that I have a hidden part on the back side that most won't even notice. It goes almost the full length eventhough it's a little hard to tell. It stops about an inch short of the uniball pivot.

I also got the bumpstops finalized and fully welded.

Officially I'm cycling exactly 15" with 7" of bump and 8" of droop from ride height basically. Shock tabs are cycling 11.5" and I'm running a 12" stroke shock so I should be golden.

Engine cage will start tomorrow afternoon. Have morning breakfast and house project plans with my parents first.

Elite Explorer members see no advertisements, no banner ads, no double underlined links,.

Add an avatar, upload photo attachments, and more!.

Similar threads

Completed Project

Turboexplorer's Full Width SAS Build Thread

- Replies

- 984

- Views

- 287,704

- Replies

- 16

- Views

- 4,113

- Replies

- 14

- Views

- 5,036

- Replies

- 14

- Views

- 2,097