Since my very first Hot Rod magazine subscription in 1992, I've been seeing ads for POR-15 claiming it's "Paint Over Rust" attributes. I've always thought it would be cool to try it out on trucks and other steel things I wanted to preserve to see how well it actually works. There are so many unseen places that are hard to reach, sand, scrape, or otherwise effectively halt rusting effects, and this is where I want to try it.

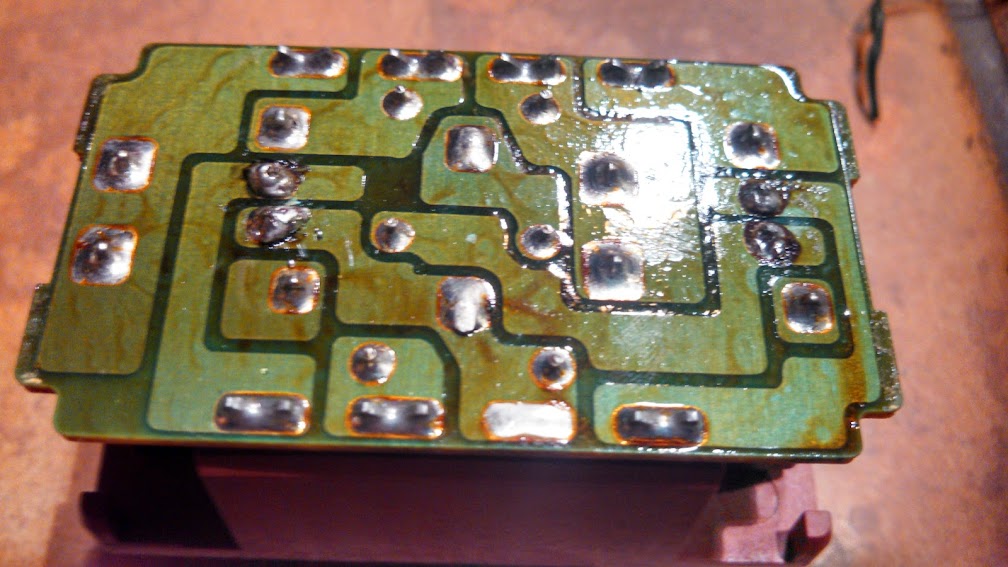

Some areas I've spent hours sanding and priming are starting to show rust ALREADY, but I know from research, primer isn't meant to stop this process; it has to be covered quickly with a finish coat. This is not available to me as I am working from the inside out, and small sections at a time, essentially. The inner fenders, frame, interior and places that aren't getting a final treatment after prep work need protection. I really hate doing work more than once, but I'm learning this by making the mistakes as I go along.

After seeing that LMC Truck is now selling POR-15, it made me re-visit the idea that this may be the ultimate solution for this project. It is not cheap stuff, in fact at $165/gallon or $50/quart it is somehow more expensive than my wife's makeup

Luckily for me, and anyone who wants to first try a sample amount, there is an awesome kit for $22 or so, which you can purchase online or find locally. I used their website:

http://www.por15.com/ to locate a local distributor that had this same kit priced at $20.08. Not only was it cheaper, I didn't have to pay for shipping, OR WAIT FOR DELIVERY!!!

This "Super Starter Kit" comes with all the necessities as they state: "You'll get a 4 oz. can of POR-15® Gloss Black (enough to cover 6 square feet with 2 coats), a half-pint of POR-15® Metal Prep, two wooden handle paint brushes, and a pair of our special high-dexterity surgical latex gloves, PLUS an 8-ounce bottle of our famous POR-15® Cleaner Degreaser, the world's greatest WATER BASED degreaser.

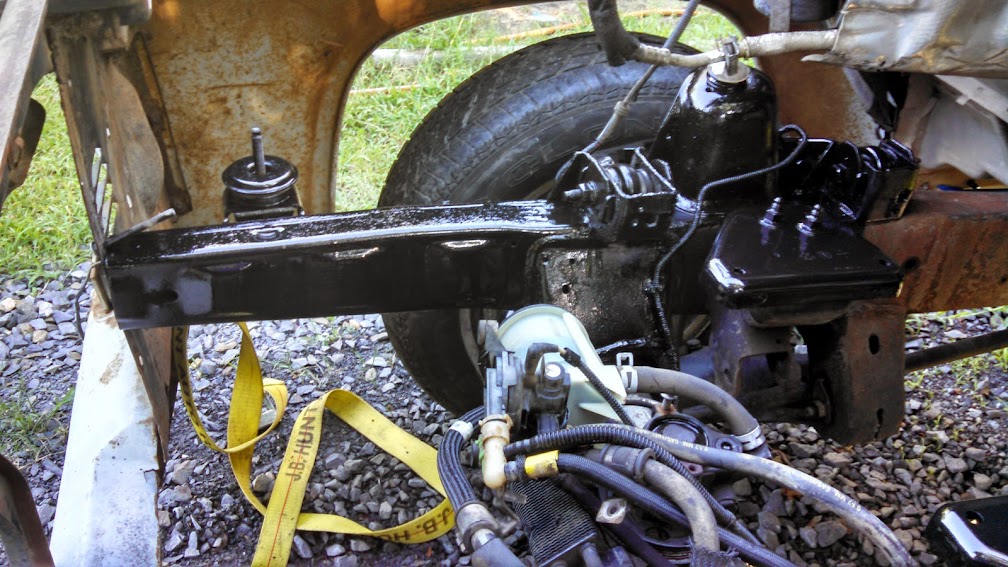

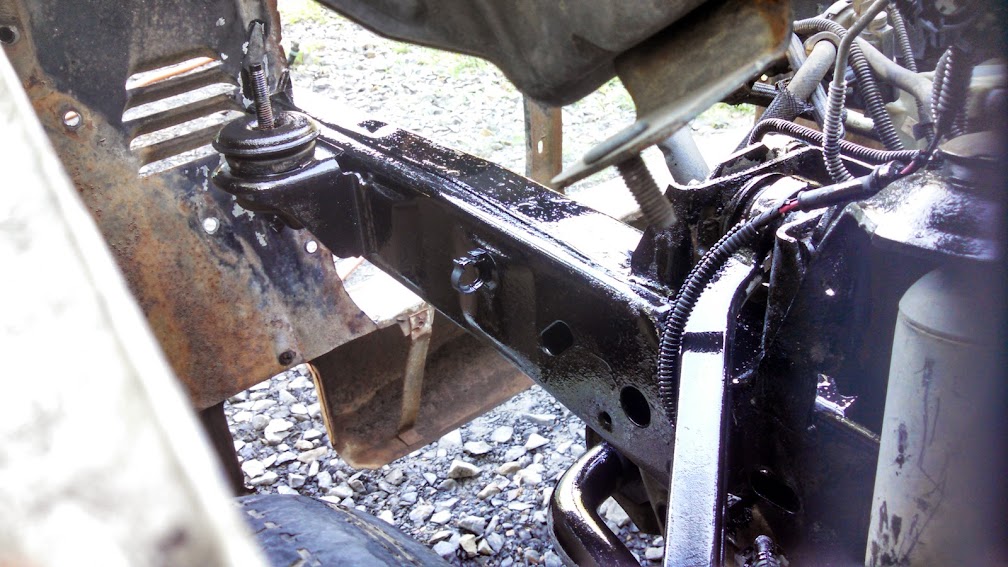

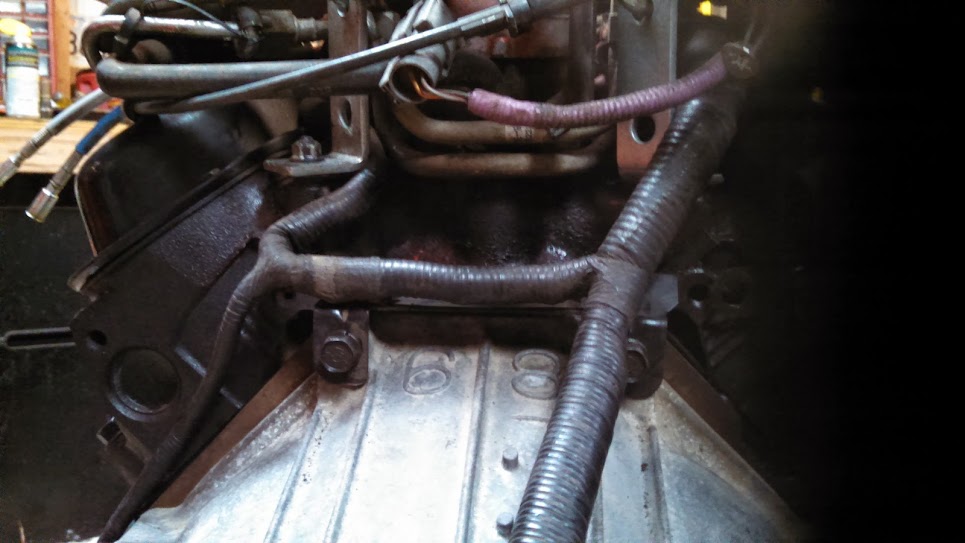

I have been using oven cleaner and degreasers repeatedly since the removal of the engine and I'm comfortable with any remaining amounts that are not noticeable as they surely won't be noticeable once everything is back in place. I think that once I get to the point where I am working on the suspension, brake components, and other individual sections, I will focus on those areas with this treatment at that time, but my main goal today was to prepare the engine bay area so that I can start the process of engine installation in the near-future (I'm excited about that!)

I started to clean with their degreaser, mixed 1:1 with hot water, ans sprayed it on liberally. I used a rag to keep it moist and working it into anywhere I would be soon painting.

The areas should remain wet with the cleaning solution for 15-20 mins and then rinsed off. Time to sit back and enjoy a break, or wash another car while you have a hose in your hand

Next, it was time to use the Metal Prep, I used a sprayer again to wet the areas and let it do its etching to ensure a proper bond for the final coating.

This is what they say about this step: "POR-15® Metal Prep provides the best adhesion for POR-15® Rust Preventive Coating on any metal surface, including aluminum and shiny polished metal surfaces. Our simple process gently etches metal, creating an ideal anchor pattern for coatings such as POR-15® Rust Preventive Coating, while simultaneously leaving a zinc phosphate coating to insure chemical bonding of paint and steel. Avoid other preps that may leave harmful residues which prevent proper adhesion. After thoroughly degreasing your work piece, apply environmentally safe POR-15 Metal Prep to both neutralize any rust and etch any clean bare metal. This will allow better adhesion of POR-15® Rust Preventive Coating or any other coating. POR-15® Metal Prep is not caustic, corrosive, toxic or flammable."

After application for 20+ mins, rinse off again. Once it's dry, a light haze (zinc phosphate) will appear.

Of course, none of this is as fun as the next step!!!

***WARNING*** The POR15 coating you are about to witness has possible undesirable effects; it will permanently stain fabrics, permanently coat solid surfaces, and stain your skin for several days. Use protective (but disposable) clothing and coverings on anything that may come into contact with this stuff. You have been warned!

This is the moment I have dreamed about for over 20 years! My first POR-15 coating!

I'll take more pics of it tomorrow evening after it's been dried and cured 24 hours to show how it looks. It should be somewhat glossy, but a matte finish is capable of being added as an additional top coat if desired.

Here's some additional info they say about it:

POR-15® Rust Preventive Coating is a high performance coating designed for application directly on rusted or seasoned metal surfaces. POR-15® Rust Preventive Coating is non-porous and seals and protects many surfaces from water, chemicals, salt, and other corrosive contaminants. POR-15® Rust Preventive Coating is an effective anti-corrosive and rust preventive coating that offers superior chemical resistance due to its dense, cross-linked molecular composition and non-porous attributes.

The secret lies in POR-15® Rust Preventive Coating's curing process. Most paints dry through evaporation, but POR-15® Rust Preventive Coating dries faster when moisture is present. It has the opposite chemistry of ordinary paints. Now add to that POR-15® Rust Preventive Coating incredible hardness, toughness, and flexibility and you have a coating that is practically indestructible. POR-15® Rust Preventive Coating is great for auto restoration, and protecting valuable equipment against rust and corrosion. You'll be amazed at the toughness!

There's a lot of cool stuff on their website as well as other places on the interwebs. Check it out and.....

TO RUST!!!

We 50's Ford owners are ELITE

We 50's Ford owners are ELITE