SO I guess the time has came early for my 5.3L LS swap on The Black Pearl!!

LET THE HATE BEGIN!!!

I have a buddy that is a drag-racer but started working for a ****ty speed shop in the area and now he is burnt out from engines and all that; He is getting into guns and i have built a few ARs. We did some talking the other weekend and we figured that one of my ARs is worth about the same as his 400-450 horse Gen3 LM7 (706 heads, Gen4 internals. Titanium valve springs, retainers and guides)

Currently the piston rings are gaped and it has a cam setup for spray but he just hadn't gotten around to get nitro setup in the car yet. This is in a late 80s Monte Carlo BTW.

This are some pictures i loaded on my SAS build thread so i will post them up here to keep it all in one place.

This is just a general picture i found on google but thats pretty much the setup i am getting.

This is just a general picture i found on google but thats pretty much the setup i am getting.

I have some 2010 Camaro exhaust manifolds that will be used (IF they fit!) that he threw in as well.

I went to the wrecking yard last weekend and picked up a 2000 tahoe fuseblock, harness, MAF and PCM for $40.65 out the door.

Started pulling it apart and removing ALL un-needed circuits, Factory fuse block, A/C, EVAP, Trans and a few other circuits.

i also added a few circuits such as a secondary ground circuit for the Taurus 2-speed fan i have installed. The fans are controlled by the PCM, the PCM sends ground to the fan relays to turn them on/off at set temps (that will be programmed into the PCM when it gets tuned).

This is what we have left:

To clean things up in the engine bay i am going to use a Corvette style fuel system. There is no fuel pressure regulator on the fuel rail, it in in-line on the frame rail. It also uses a return-less system incorporated into the fuel filter, with the regulator.

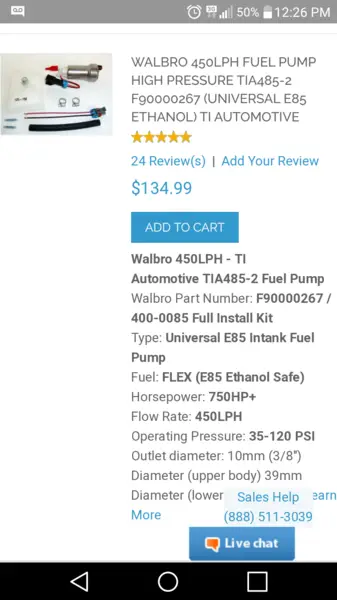

450 is overkill but this pump is a direct for to the explorer in-tank fuel pump according to Walbro.

This fuel filter will replace the factory Explorer fuel filter. It is a Corvette fuel filter with a built in fuel pressure regulator. With a return line back to the tank for unused fuel.

These engines require 60PSI fuel pressure and the 1gen explorers are only pushing around 30-40 PSI.

LET THE HATE BEGIN!!!

I have a buddy that is a drag-racer but started working for a ****ty speed shop in the area and now he is burnt out from engines and all that; He is getting into guns and i have built a few ARs. We did some talking the other weekend and we figured that one of my ARs is worth about the same as his 400-450 horse Gen3 LM7 (706 heads, Gen4 internals. Titanium valve springs, retainers and guides)

Currently the piston rings are gaped and it has a cam setup for spray but he just hadn't gotten around to get nitro setup in the car yet. This is in a late 80s Monte Carlo BTW.

This are some pictures i loaded on my SAS build thread so i will post them up here to keep it all in one place.

I have some 2010 Camaro exhaust manifolds that will be used (IF they fit!) that he threw in as well.

I went to the wrecking yard last weekend and picked up a 2000 tahoe fuseblock, harness, MAF and PCM for $40.65 out the door.

Started pulling it apart and removing ALL un-needed circuits, Factory fuse block, A/C, EVAP, Trans and a few other circuits.

i also added a few circuits such as a secondary ground circuit for the Taurus 2-speed fan i have installed. The fans are controlled by the PCM, the PCM sends ground to the fan relays to turn them on/off at set temps (that will be programmed into the PCM when it gets tuned).

This is what we have left:

To clean things up in the engine bay i am going to use a Corvette style fuel system. There is no fuel pressure regulator on the fuel rail, it in in-line on the frame rail. It also uses a return-less system incorporated into the fuel filter, with the regulator.

450 is overkill but this pump is a direct for to the explorer in-tank fuel pump according to Walbro.

This fuel filter will replace the factory Explorer fuel filter. It is a Corvette fuel filter with a built in fuel pressure regulator. With a return line back to the tank for unused fuel.

These engines require 60PSI fuel pressure and the 1gen explorers are only pushing around 30-40 PSI.