- Joined

- January 14, 2001

- Messages

- 6,268

- Reaction score

- 291

- City, State

- Fresno CA

- Year, Model & Trim Level

- 86 ranger no more

- Callsign

- KK6TDL

If you didnt figure it out from the title I am trying to keep the stock 4.0 then put an NP435 transmission behind it then to duel ranger tcases. This will give me a 6.69 first 2.48 gearing in each tcase then my axles right now are 3.73. With lower gears in the axles you can easily end up with a crawl ratio in the 200 to 1 range. Not only that I am shooting for the NP435 and crawler box to be the same length as the stock ranger transmission so that my driveshaft lengths will be the same length as stock and I wont have to move my gas tank.

While I will be losing overdrive I will be picking up a super low first gear. My ranger is a second vechicle so highway manners are not as important to me. There will be a bit of a gap when shifting from second to third with the new tranny in. Hopefully it will be OK.

I am still kind of early into this project and havent figured out all the details on how to make it work. I also dont have access to a full machine shop. Pretty much my hightech tools include a $200 harbor freight drill press ( a real POS) a 4.5" grider and some drill bits. Hopefully I can get it all worked out. Anyway on with some pictures

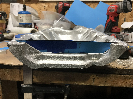

Here you can see the size difference between the np435 and the stock mazda 5 speed from my ranger. Should make a tight fit in the tranny tunnel for sure. Did I mention I am trying to do this without a body lift

While I will be losing overdrive I will be picking up a super low first gear. My ranger is a second vechicle so highway manners are not as important to me. There will be a bit of a gap when shifting from second to third with the new tranny in. Hopefully it will be OK.

I am still kind of early into this project and havent figured out all the details on how to make it work. I also dont have access to a full machine shop. Pretty much my hightech tools include a $200 harbor freight drill press ( a real POS) a 4.5" grider and some drill bits. Hopefully I can get it all worked out. Anyway on with some pictures

Here you can see the size difference between the np435 and the stock mazda 5 speed from my ranger. Should make a tight fit in the tranny tunnel for sure. Did I mention I am trying to do this without a body lift